Not conduction, not convection,

Now it is the era of

Radiation

Coffee Roasting

For the entire history of coffee roasting, we've fixated on using conductive (hot metal drums) & convective (hot air) roasting methods.

However, this means that for this entire time, one of the most efficient way of heat transfer has been criminally overlooked - namely, direct radiation.

Here at rubasse, we vision a future where coffee roasters around the world can harness the full power and benefits of radiation heating technologies.

With the new fully electric, NIR radiation driven Nano Pro 1s coffee roasting machine, Rubasse & our users thrive to obtain cleanness & sustainability both in the cup and for the earth.

Commercial electrical roasting machines usually gives the impression of being sluggish and slow, needing a lot of anticipation and "guessing games" when adjusting the roast controls.

The opposite could be said about our Rubasse roasters.

Since the appearance of our Micro 3kg roasters, with the help of our NIR heating technology, Rubasse roasters has become one of the most responsive and powerful roasting machines out on the market (including gas-powered machines!).

And now, bringing the roast capacity from 3kg to 150g, the brand new Nano Pro 1s small batch roaster promises to give roasters and coffee afficionados the same unique roasting experience - just in a more compact and agile form.

Roast it the way you like it

Backed by our cutting-edge Near Infrared (NIR) radiation roasting technology, the Nano Pro 1s achieved top-class roasting responsiveness, controllability, and stability rivaling professional specialty production roasters on the market — all while needing only a mere 1650W power input at most!!

Counter-top & hassle free

Fully electric

+

Small, adjustable footprint

+

25kg weight

+

110V / 220V household plug power supply

+

Industrial grade stability and controllability

=

Professional quality roasts conveniently and consistently

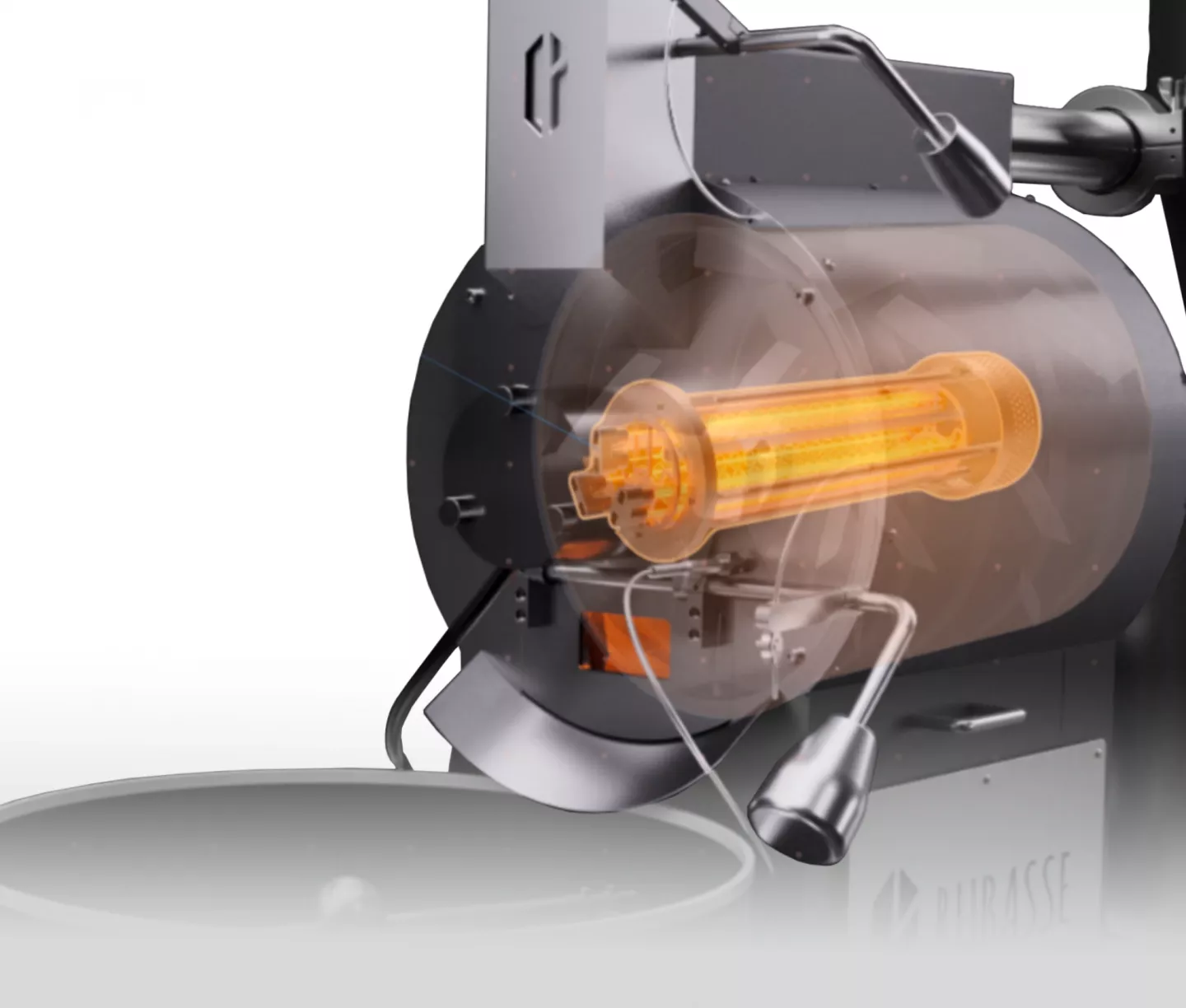

Center-placed NIR Radiation -

Powerful, Accurate, Efficient

By directly applying the roasting energy onto the beans via radiation, we made roasting more energy-efficient than ever.

This also gives roasters ultra instinct & straightforward control over the heat energy applied at any stage of the roast — simply by adjusting the heat setting with a touch on the control panel.

Precise control over your roast -

All at your fingertips

Just like our larger roaster models, all roasting functions are controlled via the touch panel, making live roasting adjustments straightfoward, easy, and swift.

The one-page interface design makes sure that all the adjustments are only one touch away at anytime during roasting.

200~600g roast capacity

Unlimited back-to-back roasting

The efficiency of our center-placed NIR radiation heat source minimizes heat energy waste & overheating of the stainless steel roasting drum & components.

This allows roasters to do back-to-back roasting throughout the entire roast day without worrying about overheated metal parts intefereing with both the roast controls & the final product flavor.

Focus on creation.

Let us do the repetitions.

Replicate your previous roasts in 3 easy steps :

1. Search and select the saved profile

2. Press "Auto", wait for automatic preheat to complete, then charge the beans

3. Drop the batch — your done!

Paired with the super-responsive heating of the NIR heat source, our specialized PID-based roast replication system automates the repetitive roasting process for you with precision & repeatability.

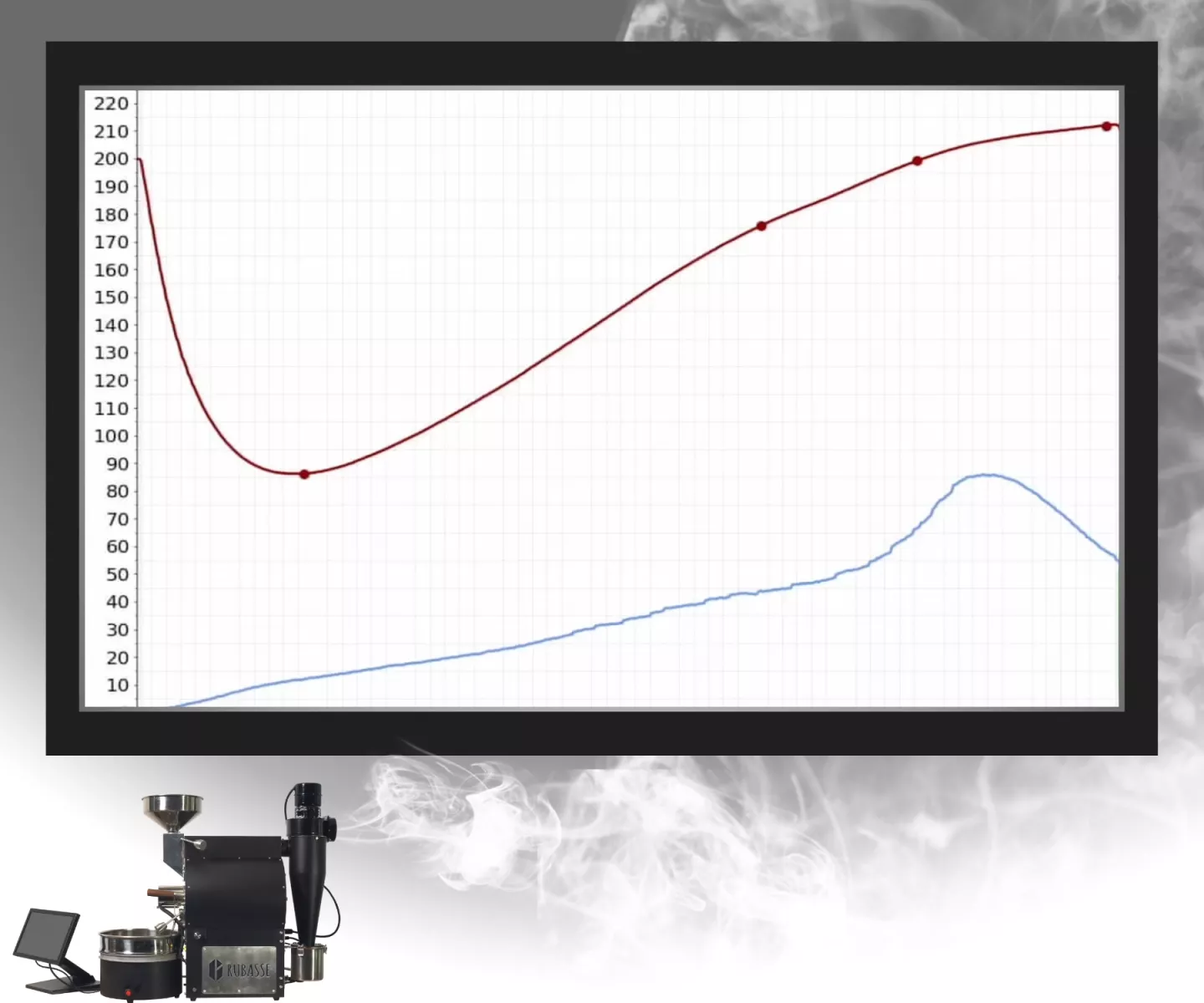

Roast moisture sensor

Opening up a new dimension of roasting control & profile design.

Roasters have long talked about the "drying phase", "dehydration", & "release of moisture" throughout the roast process. On the Nano Pro 1s, we actually visiualized it for you — with precision and repeatability, again.

With this special data now available, roasters might actually get a whole step closer to the essence of coffee roasting, opening up new possibilities regarding profile design, and push the boundaries of specialty coffee further once more.

Things that you can use the moisture sensor for :

1. Determine when the "first crack" actually occurs

2. Determine when it is best to end a roast for optimal flavor/tactile qualities

3. Determine when and how to adjust the airflow throughout the roast

......and possibly much, much more ( combined with the other roasting sensors, the potential here really is infinite!! )

Specifications

Electrical

Total power required : 1650W

Roaster voltage : 110 or 220V

Drum rpm : -100 ~ +100 rpm

Panel voltage : 100 ~ 240V

Overall

Max roast capacity : 600g

Min roast capacity : 150g

Cooling : specified exhaust

Roaster weight : 25kg

Cooling tray weight : 2.8kg

Footprint : L55*W30*H65 cm

Touch panel : 15.6 inch

Roasting Sensors

Comes with :

Bean temperature sensor

Air temperature sensor

Roast moisture sensor

Differential pressure sensor

Roasting Software

Lv.3 Rubasse profile replication system

(same level as our Micro Pro model roasters)