Coffee Roaster Automation:The 4 different levels of automation nowadays & 3 things to consider before deciding which one to buy

Coffee Roaster Automation:The 4 different levels of automation nowadays & 3 things to consider before deciding which one to buy

You have finally decided to start your own coffee business. Congratulations. After deciding the ideal espresso machine, the best-tasting grinder(s)......etc., you now decide to take a good look at one of the cornerstones of a great coffee shop: the coffee itself.

If you decide to take matters into your own hands, you might already be looking for a coffee roaster. To aid the process of production roasting, you might even be looking for one that has some kind of automated functions. However, after searching around online, you might start to get the feeling that when a roaster manufacturer claims to include “automated function”, the level of automation could vary greatly.

We now would like to provide a quick and simple guide about the current levels of coffee roaster automation (from our point of view) for those looking for their ideal machine.

To make automated roasts possible

Before we start to talk about the different levels of automated functions, we have to address some of the basic requirements that must be fulfilled in order to achieve any kind of roaster automation:

-

Digitized controls: To let the roasting system roast automatically for you, important control features such as burner/power output, airflow settings, and drum speed must be digitally controllable.

-

Data recording: This is a must if you want to roast automatically using any kind of software/control systems. The quality (stability, reproducibility, precision) of the recorded data is also crucial.

-

Automated roaster functions: Imagine this: you had replicated an ideal roast curve perfectly using the best-tuned automation systems and data from the most precise temperature probes available. However, when the roast came to the desired ending point, the roaster didn’t automatically drop the batch of coffee for you because the discharge gate cannot be operated automatically. Since you were being occupied with other roastery tasks, you missed the dropping point. You had roasted the perfect batch with a perfectly replicated roast profile - however it was dropped 15 seconds later than expected. The coffee tasted darker than you prefer it to be. Not ideal.

This is where the seemingly basic idea of roaster function automation can have a big impact on your whole production flow. Definitely something we would recommend you to take into consideration.

The 4 different levels of automation

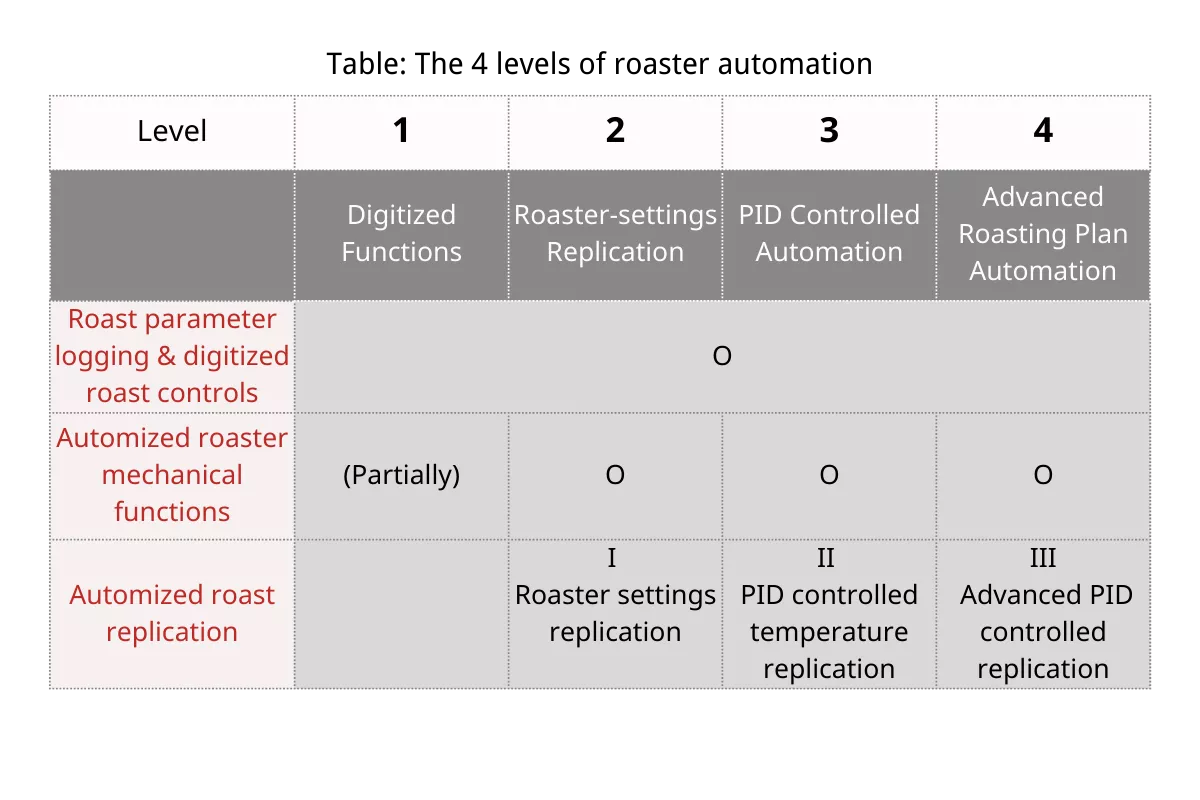

After covering the basic requirements that lay the foundation of automated roasting, we can now talk about the 4 different “levels” of automation.

Lv1 - digitized functions :

These roasters are no longer the traditional, manually controlled coffee roasting machines. It may have features such as roast data collecting sensors, digital display, digitized gas settings…etc.

Lv2 - roaster-settings replication :

Based on digitized controls, the roaster can now “replay” your recorded roast adjustments automatically for you. However, this does not guarantee that you can obtain the same profile again, let alone having the same results in the cup.

Lv3 - PID controlled automation :

To obtain more precise bean temperature replication, PID controlled roast replication systems will tweak the gas/power settings automatically, compensating for any deviations from the desired roast profile during automatic roasting.

Lv4 - Advanced roasting plan automation :

On top of PID controlled bean temperature replication, the system will also take other roasting parameters into consideration when replicating a previous profile. The replication target might not solely be the bean temperature only. This can lead to results that are more “accurate” flavor-wise / roast color-wise when compared to the only PID bean temperature replications.

More about the difference between Lv2 to Lv4 automation

As shown in the table above, the main difference between Lv2, Lv3, and Lv4 automation mainly lies in “how” the system replicates the profile and “which parameters” are taken into consideration during replication. Below are some more info regarding the three main ways used in Lv2, Lv3, and Lv4 replication systems, respectively.

-

I Roaster-settings replication

-

As if “replaying” what you have done last time, the system only replicates the burner/power, airflow, and drum speed settings exactly as recorded in the profile.

-

The most basic form of roast replication. Results may vary greatly in both flavor and roast color due to differences and fluctuations in environmental conditions.

-

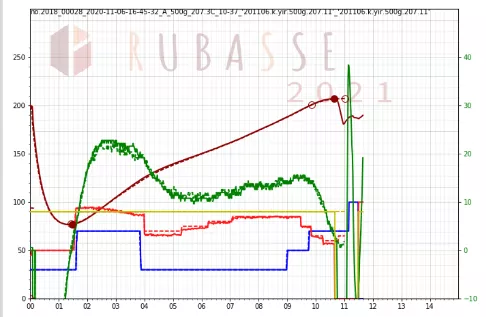

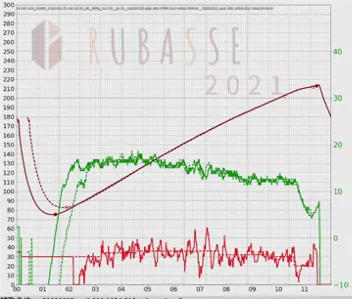

(The graph above is the comparison between a profile recorded during winter vs the profile resulting from settings-replication done during summer. One can see that under the same power, airflow, and drum speed settings, the roast still runs way faster during summer.)

- II PID controlled temperature replication

-

The system automatically adjusts the burner/power, targeting the recorded “temperature” reading in the profile. This could be bean, environmental, air, or any other temperature readings depending on the roaster's design.

-

Have the ability to neutralize differences in roasting environment conditions to a certain extent.

-

Most roast replication systems nowadays fall within this category.

-

(The PID controlled replication system compensates for the slight differences in the bean temperature profile, resulting in a much more closely followed replication of the bean temperature profile.)

-

III Advanced PID controlled replication:

-

Not only aiming for the replication of the selected temperature reading(s) in a profile, advanced PID controlled replication also manages to replicate differential pressure profiles and the desired rate of rise (RoR).

-

Has the ability to further neutralize differences in environmental conditions, allowing for even more precise roast replications. Also, these kinds of advanced replication systems opened the possibility of using the same profile to roast different batch sizes (of the same beans).

-

The 3 things to consider - what kind of automation is best for me?

-

Are you mainly selling darker roasted blends or specialty coffee?

-

For Specialty coffee: There might simultaneously be more kinds of different coffees on the menu. Also, freshness of the roasted beans is more important, and the usually lighter roast degree paired with the more complex specialty coffee flavors means increased difficulty when trying to replicate the same end product. [Recommended: Lv3, Lv4 automation]

-

For darker roasted blends/commodity coffee: Stability and automated roasting efficiency is the main goal. This means that any reasonable roaster automation might already be more than sufficient. [Recommended: Lv2 to Lv4 automation]

-

-

How long is your typical green coffee turnover?

-

If a certain bag of greens could be sitting in the corner for more than a month (even months), now you might have to factor in fluctuations in weather conditions & changes that may occur in the green coffee itself. [Recommended: Lv3, Lv4 automation]

-

If the turnover for a bag of greens is less than a month, fluctuations might not cause issues. [Recommended: Lv2 to Lv4 automation]

-

-

Roasted beans inventory management

-

If freshness is one of the main goals, you might inevitably have to roast in smaller batch sizes and roast more frequently, working on the same bag of green coffee for a longer period but still hoping to have similar final products every time. This means that you really must factor in fluctuations in environmental conditions and try your best to neutralize them. [Recommended: Lv4 automation]

-

Additional: Chasing the perfect replication

Although having excellent roaster automation functions and systems is really an important component of a great roast replication, having suitable, dialed-in equipment is only half of the work. To ensure good replication results over a extended duration, one should also aim to have:

-

Good, reasonable storage for the green coffee

Afterall, if the green beans that are being roasted aren't stable enough, we would always be chasing a moving target when we try to replicate last time's results.

Note: Regarding “how” to preserve green bean quality: It is a whole different topic that needs much more explanation than what can be fitted in here. (If you want to read more regarding this topic, here is an article for you)

- Ambient roasting conditions that doesn’t vary too drastically

If you want to have any kind of roast consistency over some period of time, then please make sure that you are not roasting outdoors. Having advanced automated heat compensation systems can mitigate the difference in environmental conditions to a certain extent, but if the ambient temperature or other conditions (e.g. humidity) differs too much, then asking any roasting machine to guarantee you a similar roast replication result is simply a task that is physically unlikely to be done.

Also, getting to know the stability of the roaster’s energy supply (no matter if it's LPG, natural gas, or electricity) can also improve your chances to successfully replicate roasts and maintain quality standards over time.

We all aim to serve our customers great, delicious coffee. With the aid of automation technologies, roasters can have greater confidence in producing their best coffee over and over again, making sure that the positive customer experience accumulated can be preserved and maintained.

As we come to the end of this article, we hope that you now have a better idea about the seemingly complex world of automated coffee roasters and what might be suitable for you and your business.