The Roast-Master (RM) system: roasting with flexibility

One Roast Curve to Fit All Batch Sizes

TOC:

- The Roast-Master profile replication system: What’s new?

- Batch size-based automation system: Managing different batch sizes with only one roast profile!

- Tips and tricks for tuning and roasting with the RM profile replication & Batch size-based automation system

- Test Roasting using the Batch size-based automation system "with cupping results comparison" Closing words

“How often people speak of art and science as though they were two entirely different things, with no interconnection. That is all wrong. The true artist is quite rational as well as imaginative and knows what he is doing; if he does not, his art suffers. The true scientist is quite imaginative as well as rational, and sometimes leaps to solutions where reason can follow only slowly; if he does not, his science suffers.”

– Isaac Asimov

Coffee roasting is art. Just like culinary, roasters operate within the limits of their raw ingredients, searching for the balance that fits their preferred aesthetics and creating an experience that conveys their own interpretation of coffee. However, with the rise of data collection during roasting and the widespread usage of roast profiles, coffee roasting discussions these days sometimes seem more fit in a laboratory rather than a neighborhood cafe. With all the temperature profiles, rate of rise (RoR) curves, moisture content and density measurements, one might start to wonder: has the artistic part of specialty coffee been long gone?

For us, the answer is no. The artistic part of roasting, the craftsmanship, is definitely still a core element of specialty coffee. All this seemingly scientific and sometimes daunting technology only serves one sole purpose: allowing roasters to gain a more profound understanding so that they can roast with greater confidence and precision. Of course, there is also the possible benefit of being able to “replicate” a roast you like using the recorded data.

This brings us onto today's topic: profile replication.

Under most circumstances, when we talk about a roast profile, 99% of the time we are talking about the profile recorded by the “bean temperature probe”, which is the closest representation of the coffee’s temperature we can get throughout the roasting process.

So one might think: To do a replication roast, we should really focus on replicating the bean temperature profile, right?

The answer is both a yes and a no.

The reason why simply replicating the bean temperature profile might fail lies in the details: it turns out that “how” you attempt to do the replication is also a determining factor ( spoiler: it is probably an even bigger factor than whether the profile looks exactly the same! )

The Roast-Master profile replication system: What’s new?

To put it simply:Different from the commonly seen roast profile replication systems, The Roast-Master (RM) profile replication system wouldn’t simply aim for the “exact” replication of the bean temperature profile ( especially in the earlier stages of the roast ). This has multiple benefits, and a major one is that it greatly reduces the chance of a “runaway” roast in the later roast stages due to attempting to match the roast curves early in the roast and overcompensating the heat.

(This GIF demonstrates how the RM profile replication system deals with deviations from the intended profile.)

We can also touch on this from a more technical perspective:

In order to make profile replication systems come true, the majority of roasting machine manufacturers use an automatic control design that’s called PID ( Proportional–Integral–Derivative. Here’s the wikipedia link for the ones that are more geeky/tech-savvy ). Without going too much into the engineering details here, we can see this system as a way to more accurately “chase” a desired target ( for coffee roasting the target would be a certain temperature reading ).

However, if we only set the bean temperature readings as our sole target, the system may overcompensate the heat settings when the temperature is lacking behind, and then find out later that it has no choice but to dramatically drop the heat due to the roasting environment's total energy being too high already.

These kinds of large swings when adjusting roasting heat settings often leads to an unstable roasting environment and can be detrimental to the roast quality even if the final target temperature is reached at the same time as recorded in the target profile.

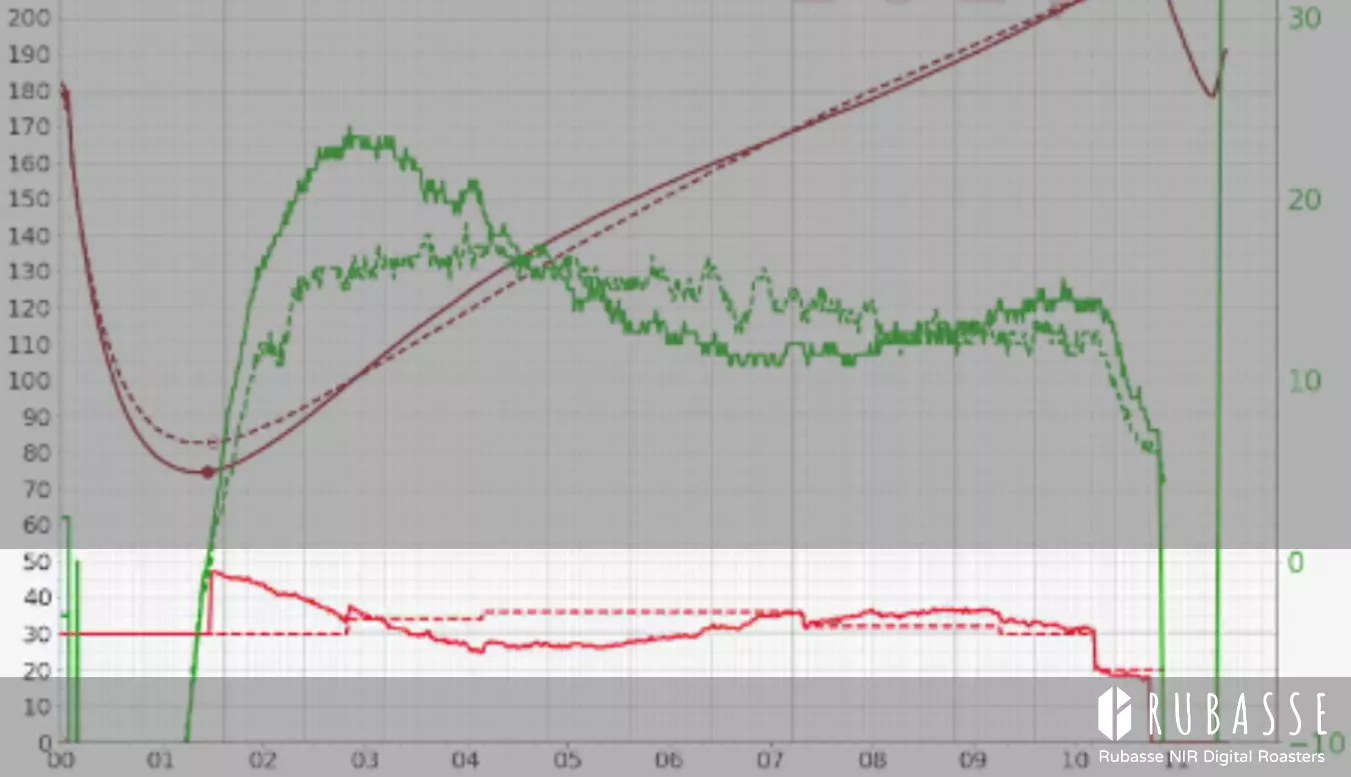

( As shown in the graph, when the turning point turns out to be lower than the profile’s, a common PID designed roast replication system overcompensated the heat settings, leading to the back-and-forth heat adjustments in the later stages throughout the whole roast. )

To counter this issue, the RM profile replication system takes additional roasting parameters ( such as “rate of rise” or RoR data ) into consideration when replicating a roast profile.

This additional design ensures the profile replication system would not only aim to hit the target temperatures but also would do it in a more “controlled” manner, making sure the roasting environment is under stable condition.

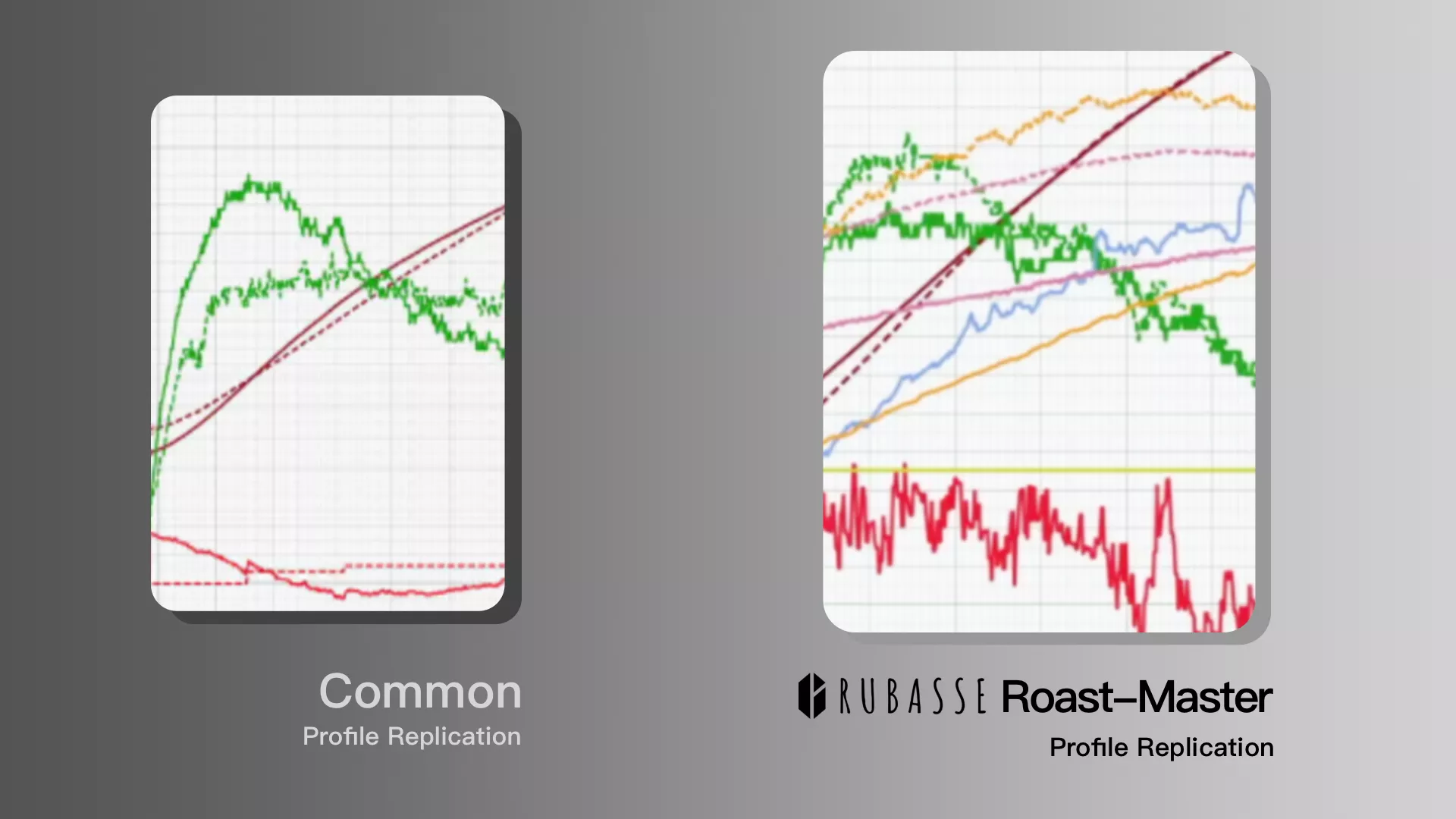

Besides tasting the final coffees ( which in our opinion greatly manifests how different the two systems can be ), the difference between a common profile replication system and the RM profile replication system can also be clearly seen when comparing how the system adjusts the heat application settings. Readers can take a look at the two replicated profiles below to see it for yourselves.

(Profile comparison for a common profile replication system and the RM profile replication system. Notice the difference in how the two systems adjust the heating power setting in particular. The normal profile replication system adjusts the power more gradually, but has an overall “trend” to over/under adjust the power; The RM profile replication system has a power profile that oscillates more, but the overall trend remains in a more “neutral” position.)

Batch size-based automation system: Managing different batch sizes with only one roast profile!

Now since we have covered what the RM profile replication system is, it’s about time to talk about something even more unique and interesting: the Batch size-based automation system.

First, please allow us to make some huge claims:

With the Batch size-based automation system, roasters can now roast different batch sizes of the same coffee (on the same roasting machine) and obtain very similar flavors – and all the roasts are fully automated!

Since we know that different batch sizes in the same roasting machine would react differently to the heat applied, if we want to roast the same green coffee and obtain a similar end product, merely making sure that two different roasts with different batch sizes both track along the same bean temperature profile could not give you the results you want.

This is where the RM profile replication system comes into play. With the help of the RM profile replication system, automated roasts now obtained the ability to “compensate” for the various differences that come with roasting different batch sizes. The result: two different-looking roast profiles for the two automated roasts but great similarity in the cup.

( For those who want to look into the details regarding the tasting results, cupping results comparison would be given later in this paragraph. Unfortunately we cannot let every reader have the chance to taste the coffees by themselves, so for now, you have to trust us on the tastings and comparison results. )

In the next part, we would take our readers through how exactly the RM replication system and the Batch size-based automation system works.

Tips and tricks for tuning and roasting with the RM profile replication & Batch size-based automation system

When we design the Batch size-based automation system, the first thing that came into our minds was to streamline the whole batch size adjustment process.

So, when roasting with the Batch size-based automation system, the user only needs to read a previously saved profile, change the batch size setting from the touch screen control panel, and simply press “Auto”. The roaster, now controlled by the Batch size-based automation system, will use the loaded profile as reference and adjust various different roast parameters by itself.

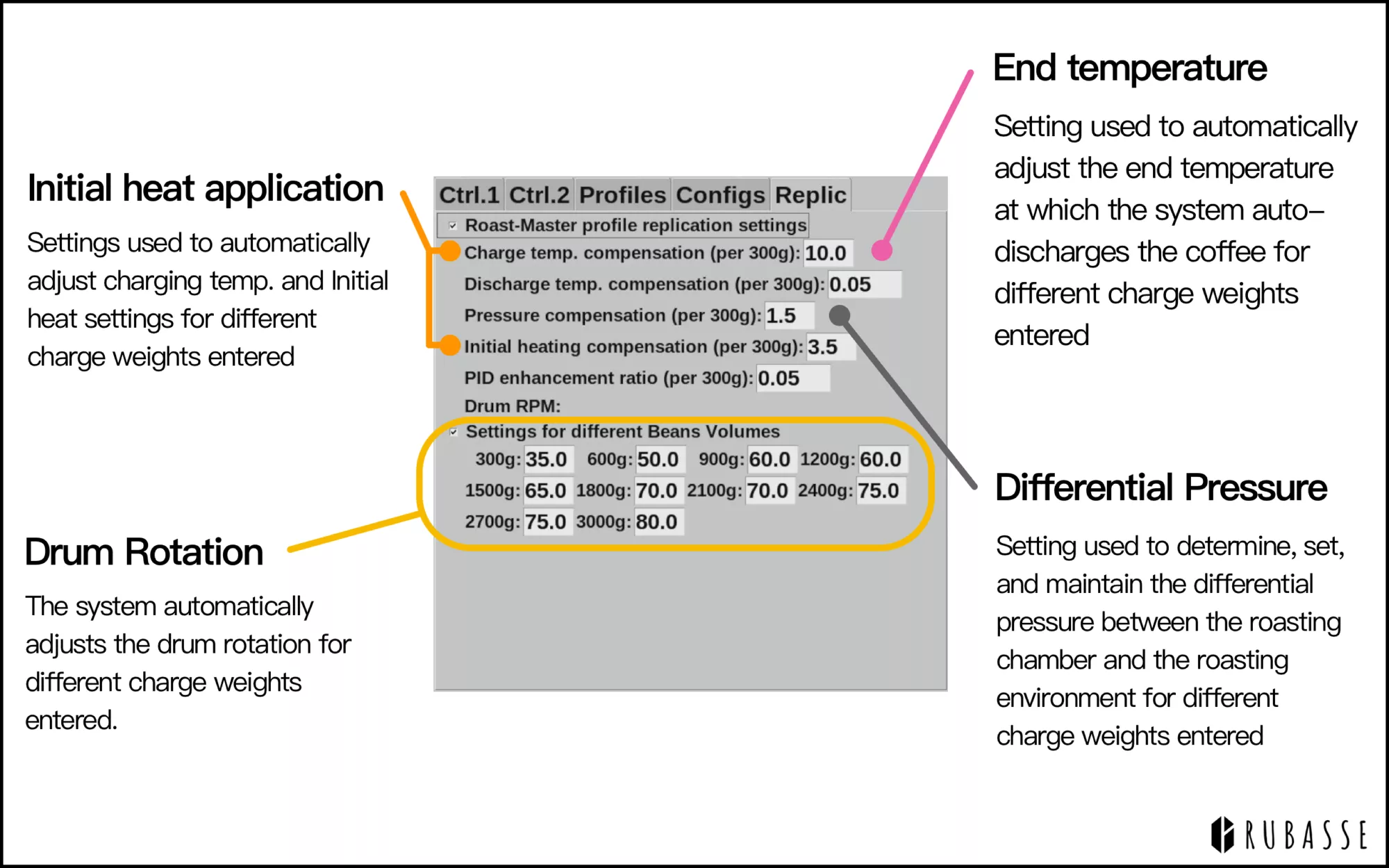

Below are a list of the parameters that the system will automatically adjust:

- Charge temperature & Initial heat setting: For a larger batch size, the system will up the charge temperature and the Initial heat setting.

- Drum RPM: For a larger batch size, the system will use a higher drum RPM when roasting.

- Pressure compensation: For a larger batch size, the system will adjust the exhaust fan speed and maintain a higher pressure reading. The “Pressure” here means the differential pressure between the roasting environment and the roast chamber. Details about this setting would be elaborated in the following paragraphs.

- Discharge temperature: For a larger batch size, the system will discharge the batch at a higher end temperature reading.

Those who are paying close attention to the control panel layout might have discovered that all the parameters are compensated on a “per 300 grams” basis. That means, the logic behind batch size compensation is that for every 300 grams increased, the system will adjust and compensate a certain set value for each of the roast parameters considered. Also, some might find that the values of compensation parameters are adjustable, too.

Here, we want to let our users know that the Batch size-based automation system is not a rigid, fixed system.

We fully understand that, even when using the same roasting machine, different people roasts differently. When designing the system, we would design, test, and verify some engineering parameters and set them as the “recommended” parameter configurations. These settings are the ones that we don’t recommend users to adjust by themselves.

However, to let the users have enough freedom and adjustability to not only do automated roasts but also do it while maintaining their own unique “roasting style” (even when changing the batch size automatically), we left the Batch size-based automation system’s compensation parameters to be fully accessible and adjustable by the users.

For the following parts, we would like to share our experiences when adjusting the Batch size-based automation system’s different parameters.

For start, the first parameters we would be tuning are Drum RPM and Discharge temperature compensation.

Drum RPM

The drum RPM parameter is a roasting variable that is still under investigation: What we do know is that changing the drum RPM would affect more than just the churning rate of the beans.

However, what we found out that matters most when adjusting drum RPM using the Batch size-based automation system is: focus on trying to make the 1st crack temperature reading for all batch sizes be (almost) identical (for one particular green coffee, of course).

Here we urge users to pay additional attention when roasting a 300g batch. It has the tendency to have a 1st crack temperature that is a bit higher than other batch sizes. Increasing the drum RPM setting for 300g batches can remedy this issue to a certain extent.

For batches that are 600g and larger, all 1st crack temperature readings tend to be quite identical. So for maximum accuracy when roasting automatically with the Batch size-based automation system, 600g is the smallest ideal batch size.

Discharge temperature compensation

Anyone that has the experience of roasting more than one batch size probably knows this: for a larger batch (again, on the same roasting machine), you have to drop the batch at a slightly higher end temperature in order to make it taste similar to the same coffee roasted with a smaller batch size.

The same principle applies when using the Batch size-based automation system. However, for roasters with different roasting styles, the ideal discharge temperature compensation value differs.

Generally speaking, roasters who like to enter 1st crack with a larger RoR (faster) might find that setting the discharge temperature compensation value larger suits their roasting better; whereas roasters that roast with a more “converged” roast profile style (the profile looks more like it asymptotes towards a certain set temperature) might find that a smaller discharge temperature compensation parameter is more ideal and gives better roast replication results.

The GIF below demonstrates the process of using the Batch size-based automation system with different discharge temperature compensation settings. In both scenarios we want to roast a 3kg batch with a 1kg profile, however, notice the different target end temperature between the two scenarios.

Also, here we would like to elaborate a little bit more on the test roasts that the readers will be reading in the later parts of this article. Since the roasting style of the test roast leans more towards the “converged” profile style, we found out that a discharge temperature compensation value of 0.15 fits our usage better (the default value is set to 0.25°C/300g increment).

How did we end up with this value, you might ask? Well, actually there is no secret method better than the good ol’ roast, cup, taste, adjust roast adjustment cycle.

The same goes for tweaking all other parameters, too. Afterall, the truth will always lie in the cup itself, so don’t be too hesitant to try out different settings: just remember to taste them all fairly and in a controlled manner (cupping is our preferred method, and weighing the ground AND water weight you put into each cupping bowl can further elevate your controllability over the testings ), you are soon going to find out what suits you and what does not.

After tuning in the first two Batch size-based automation system parameters, now we would move on to the remaining 3 other parameters: Charge temperature compensation, Initial heating compensation, and Pressure compensation. Below are some important points regarding how and why you should adjust these parameters.

Charge temperature & Initial heating compensation

It goes without saying that, when roasting different batch sizes, the initial energy requirement is going to be vastly different. This is why when roasting with the Batch size-based automation system, roasters should adjust these two vital parameters that can affect the start of any roast.

When users enter a different batch size than the original profile’s, the Batch size-based automation system will automatically do:

- Raise the charge temperature 5°C for every 300g increased.

- Add 3.5% initial heat setting for every 300g increased.

Since the Rubasse Micro RM-3 roaster has a thin, stainless steel roasting drum, the drum itself does not preserve too much heat energy. Hence, in order to adjust the different levels of initial roasting energy applied, we recommend users to leave the charge temperature compensation setting as it is, and focus much more on fine-tuning the initial heating compensation parameter.

For example, if you judge that you should apply more initial heat energy for every 300g increment in batch size, instead of setting the charge temperature compensation parameter larger, we would recommend you to use a larger initial heating compensation setting.

Note: After changing the batch size on the control panel, the initial heat setting WOULD NOT DISPLAY THE CHANGE at first. Only after the user starts the roast, the initial heating setting would automatically be set to the desired value according to the initial heating compensation parameter and the actual batch size roasted.

Pressure compensation

First, before talking about “why” you should compensate for the pressure setting for different batch sizes, we need to first know “what” exactly does the “pressure” parameter represents?

For those who already know the concept of differential pressure (or the “underpressure” as some roasting machine manufacturers call it), you can skip this part (or bear with us while we try to explain it). So here we go:

Setting the exhaust fan or exhaust damper setting to the same value will not give you the same airflow when roasting. This is due to variations in the roasting environment’s ambient pressure, temperature, and even a gust of wind might throw your airflow setting off sometimes. To maintain identical airflow throughout the roast, what one should really be monitoring is the “pressure difference between the roasting environment and the roast chamber”. Since the difference in air pressure between two different spaces is the driving force of air flowing from one space to another, If we can maintain identical pressure differences between the roasting environment and the roast chamber, the actual airflow can also be maintained better than only setting the exhaust fan/damper setting the same every time.

One could imagine that when roasting a larger batch of coffee, it’s reasonable to use more airflow. So from this viewing point, some kind of compensation must be made when roasting larger and larger batches on the same machine. However, since the magnitude of the adjustments would at the same time affect both the amount of airflow used and the temperature of the air within the roast chamber, things are far more complicated than simply just setting the fan incrementally larger along with the increasing batch sizes.

So our default Pressure compensation setting (the value being 1.5) is set due to safety reasons and not because this particular number gives the best roasting results.

This is a parameter that we recommend every roaster should really try to adjust by tasting the roast results. We would try to use values within the range 0.5 to 1.5 (of course, you might find other values out of this range to suit you better)

Caution: Here we would also like to note that the “PID enhancement ratio (per 300g)” setting you can find on the “Replic” adjustment panel is an engineering parameter. We highly recommend users to LEAVE THE SETTING AS IT IS. We designed this parameter to be adjustable by our users, but if you are not sure about it, changing it could severely hinder the performance of both the Batch size-based automation system and the RM profile replication system.

Test Roasting using the Batch size-based automation system

(with cupping results comparison)

After walking our readers through how the RM replication system and the Batch size-based automation system works, it is now the time to actually go roast some coffee.

Here we would do test roasts for 3 of the possible scenarios where the Batch size-based automation system might be greatly helpful. These are:

- 300g profile, 3kg roast: from sampling to full capacity production

- 1kg profile, 3kg roast: 3 times more efficient, unchanged quality

- 3kg profile, 1kg roast: Roasting the last bits of a green coffee with precision as usual

For cupping comparison, we decide to let two of our colleagues taste through all 3 sets of the test roast results, and we simply record what they have to say and share it with you.

Here, we can save you some time and tell you that the target and the replicated batch all taste very similar for each of the 3 experiments (of course, if it didn’t taste similar, we wouldn’t bother writing a whole article and sharing it, right?).

However, If you want to know what subtle differences there might be when doing side-by-side A/B comparisons of the target batch and the Batch size-based automation system replicated batch, feel free to dive into the details of the cupping notes.

Green coffee info:

- Region: Antigua, Guatemala

- Estate: Bella Carmona

- Processing: washed

- Variety: Caturra, Catuai, Bourbon

The selected RM replication system and Batch size-based automation system parameters:

- Discharge temp. compensation (per 300g): 0.13°C

- Pressure compensation (per 300g): 0.5

The rest of the system's parameters are left untouched. That means we use the system's default settings for Charge temp. compensation, Initial heating compensation, and Drum RPM.

300g profile, 3kg roast: from sampling to full capacity production

Sample roasting is a great way to test a newly received green coffee and know its limits. Tuning the development time (or time after crack), end temperature, and the other aspects of the roast curve using 300g is way more economical than using 3kg straight from the first go.

Here, we have found a sample roast profile that we’re happy about, and instead of translating the profile to a 3kg full capacity roast by ourselves, we let the Batch size-based automation system do the job for us.

Color reading and tasting results:

左右滑動看表格

左右滑動看表格|

300g sampling profile |

batch size enlargement |

3kg actual roasting |

|

ground agtron 69.3 |

ground agtron 71.2 |

|

|

A: The smell is more lively, feels lighter but also “spreads out” better. B: The smell seems to be a bit lighter. |

Fragrance |

A:The smell is “sweeter”, and also it feels better defined to a certain degree. B: A sweeter smell, more solid fragrance notes. |

|

A: The aroma sustains longer when smelling. As the temperature drops, this cup seems to be roasted a bit lighter. B: The aroma feels a bit more dull. |

Aroma |

A: The aroma gives a more rounded impression, and seems a bit sweeter. As the temperature drops, hints of ripe tangerines become clearer. B: The aroma seems to be more defined. |

|

A: The flavor spreads out a bit wider, with the weight of the liquid being lighter on the palate. B: Tastes good. |

Flavor |

A: A bit juicier than the other cup. Interestingly, the flavor differences between the two cups are even smaller than what the smell hints. B: Overall still tasting good, but the bitterness for this cup is slightly more profound. |

1kg profile, 3kg roast: 3 times more efficient, unchanged quality

If the roaster already have a 1kg profile that they really like but doesn’t want to only roast 1kg per production batch, no worries, the Batch size-based automation system is designed exactly for tasks like this.Simply load the 1kg profile, change the batch size to 3kg, and press “Auto”. Below is what it looks like when doing 3kg automated replication roasts using a 1kg profile.

Color reading and tasting results:

左右滑動看表格

左右滑動看表格|

1kg profile |

batch size enlargement |

3kg actual roasting |

|

ground agtron 70.9 |

ground agtron 73.5 |

|

|

A: The smell is very similar between these two cups. Probably this one has a bit more nutty notes (?). B: OK. This one is hard to tell apart. |

Fragrance |

A: Maybe this one has a slightly fruitier tone (?). B: As said before, it feels the same for me. |

|

A: The aroma is “layered” out better. As the temperature drops, smells of almond and white floral seem to pop out more. B: Still hard to tell. Sorry. |

Aroma |

A: The aroma has more of a caramel hint. Otherwise, it is very similar to the other cup. As the temperature drops, caramel and some roast notes become clearer. B: Still hard to tell. Sorry. |

|

A: The fruitiness mid-tasting seems to lack a bit, and the sweetness following it has more of a “caramel-like” feeling. Slightly more bitter aftertaste. B: Slightly more bitterness for this one. |

Flavor |

A: Fruity flavors, especially the yellow stone fruit ones, is more profound for this cup. B: At first taste, this one seemed to be a bit more acidic. |

3kg profile, 1kg roast: Roasting the last bits of a green coffee with precision as usual

Imagine this: your normal production batch size has always been 3kg. This time, you got a beautiful geisha coffee of the highest quality, and after several batches, you got only 1kg of the green coffee left.

This is really not a coffee that you would want to waste any bit of it, however, not being familiar with 1kg batch sizes, you also fear that you would simply ruin the roast.

This is one of the rarer times where one would actually want to do batch size reduction. Luckily, when using the Batch size-based automation system, one would only need to (again) change the batch size settings, and our roasting machine will have you covered.

左右滑動看表格

左右滑動看表格|

3kg production profile |

batch size reduction |

1kg actual roasting |

|

ground agtron 73.5 |

ground agtron 73.0 |

|

|

A: More caramel-like. Toffee, caramel sauce smells seems fuller. S: Fruitier with hints of apple-like smells. |

Fragrance |

A: Smells lighter. S: The fragrance seems to be more vivid. Heavier impression of “sourness/acidity”. |

|

A: Same like the fragrance, the aroma for this cup has more of a toffee/caramel sweet smell. However, after breaking the crust, this one also gives a bit of a roasty smell. S: Overall a sweeter-smelling cup. However, after breaking the crust, the roastiness is a little bit more prominent, with hints of oolong tea. |

Aroma |

A: Toffee hints are also there, but this cup seemed to feel a bit lighter. The “layers” of the aroma seemed to be more organized(?). S: Better layering of the aroma notes. After breaking the crust, some roasted nuts notes also exist, but overall this cup gives more of a fruity impression. |

|

A: First this cup seems to be the flatter one between the two. But as the cupping went on, it soon turned out to taste quite identical with the other cup, giving off notes of apples, mandarin, and orange zest. The sweetness lends more towards a “caramel” feeling. S: Heavier notes of caramel. Interestingly, although the overall feeling is heavier, it has a lighter note that resembles floral aromas. |

Flavor |

A: The fruity acidity in this cup is more prominent. But as the temperature cools down, the two cups become very similar. S: The overall impression is still lighter. However the difference is very small (kinda like the difference you might feel when brewing the same beans in the morning and then the afternoon.) |

Closing words

Congratulations. You have (finally) made it to the end of this rather long piece.

In this article we have covered what the RM profile replication system is, how it differs from other profile replication systems, and how it contributes to the development of the Batch size-based automation system. Also, we gave 3 different example uses and their result comparisons.

Safe to say, the majority of this article has been dedicated to the technical details, diving into the various details of the complicated world of coffee roasting. For some, it might even be a little bit tiring/daunting.

However, before ending, here we would like to remind our readers: the reason that we want to build these new roasting systems is not to make coffee roasting more complicated than it already can be; we simply want to liberate roasters from the burden of the various chores that’s required to adjust and tune the coffee roaster to a stable, operable condition. With the help of these systems, roasters of different experience or coming from different backgrounds can all focus more on what matters the most: roasting coffee itself and expressing their own concept of what a coffee can be.

Coffee, no matter how complicated the roasting process is or how advanced the different gadgets used during production are, is a product that’s meant to be drunk. What matters the most is and always will be whether you like the final cup or not. And that is totally up for you to decide.

What we can do, however, is to make sure that once you find your desired flavor profile, you will be able to experience and share the beauty of that spectacular cup over and over again. This is what we at Rubasse hope to achieve through our coffee roasters and the systems we develop.

Lastly, thank you for reading through. Hope you have a great day (and a great cup of coffee), and if you want to know anything more about our roasters or its systems, feel free to contact us. We are honored to be at your service.