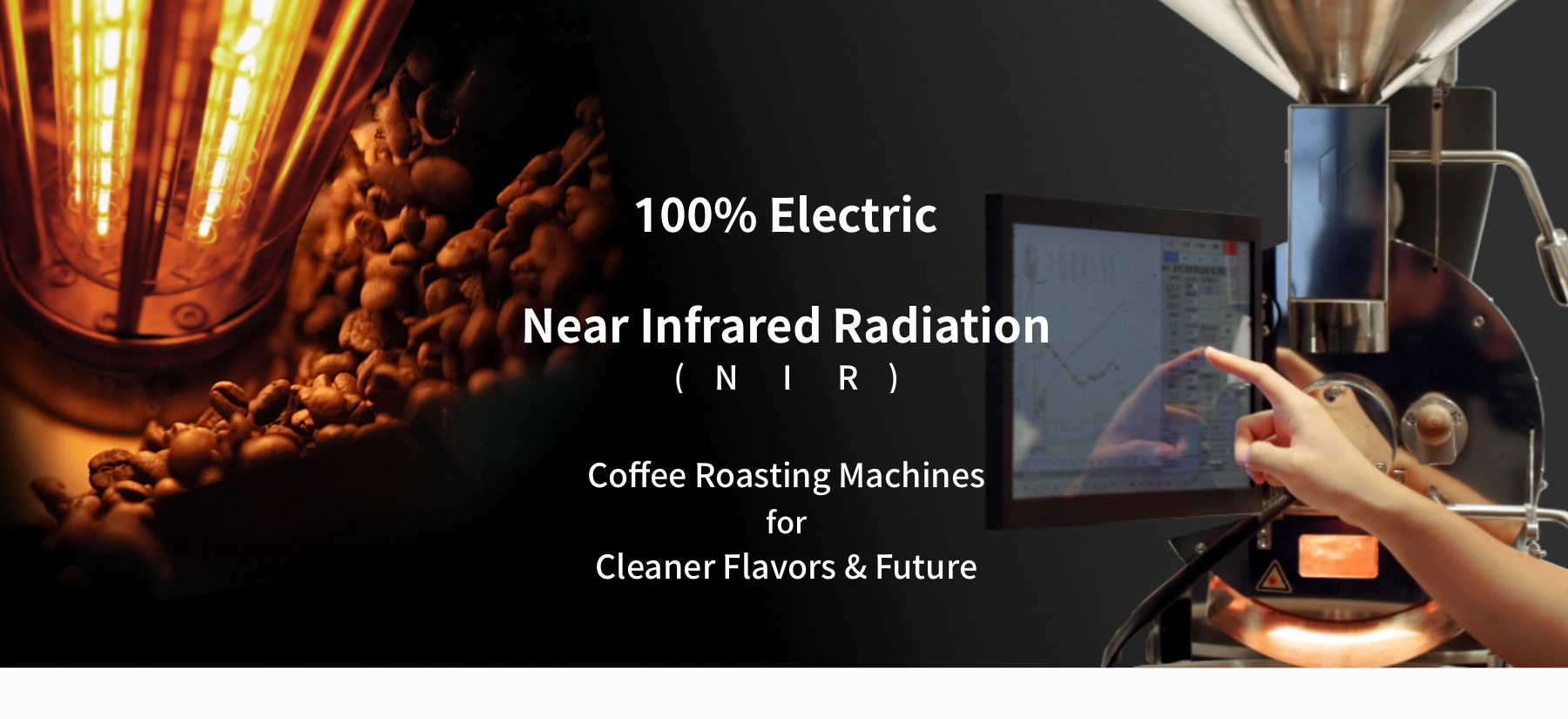

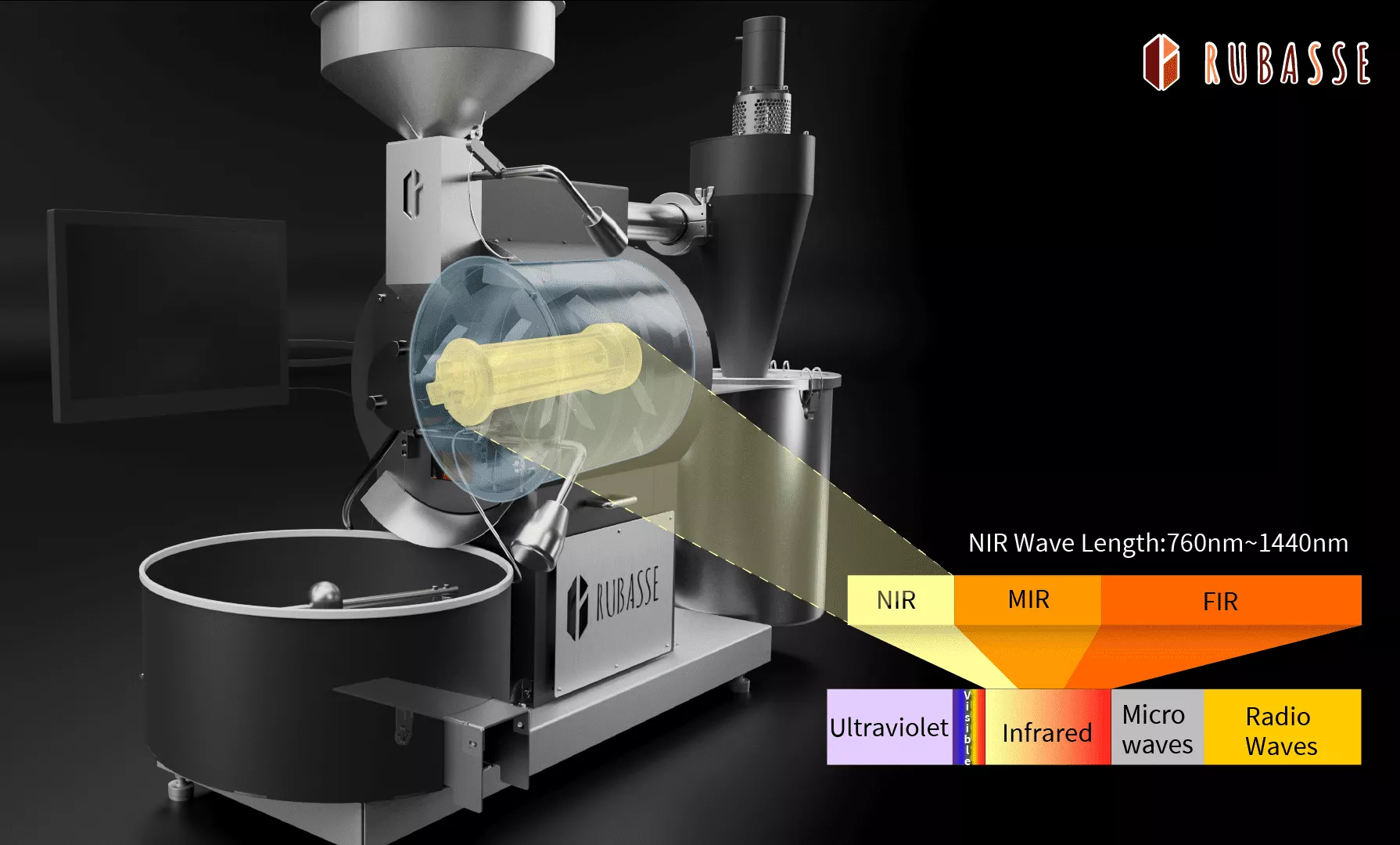

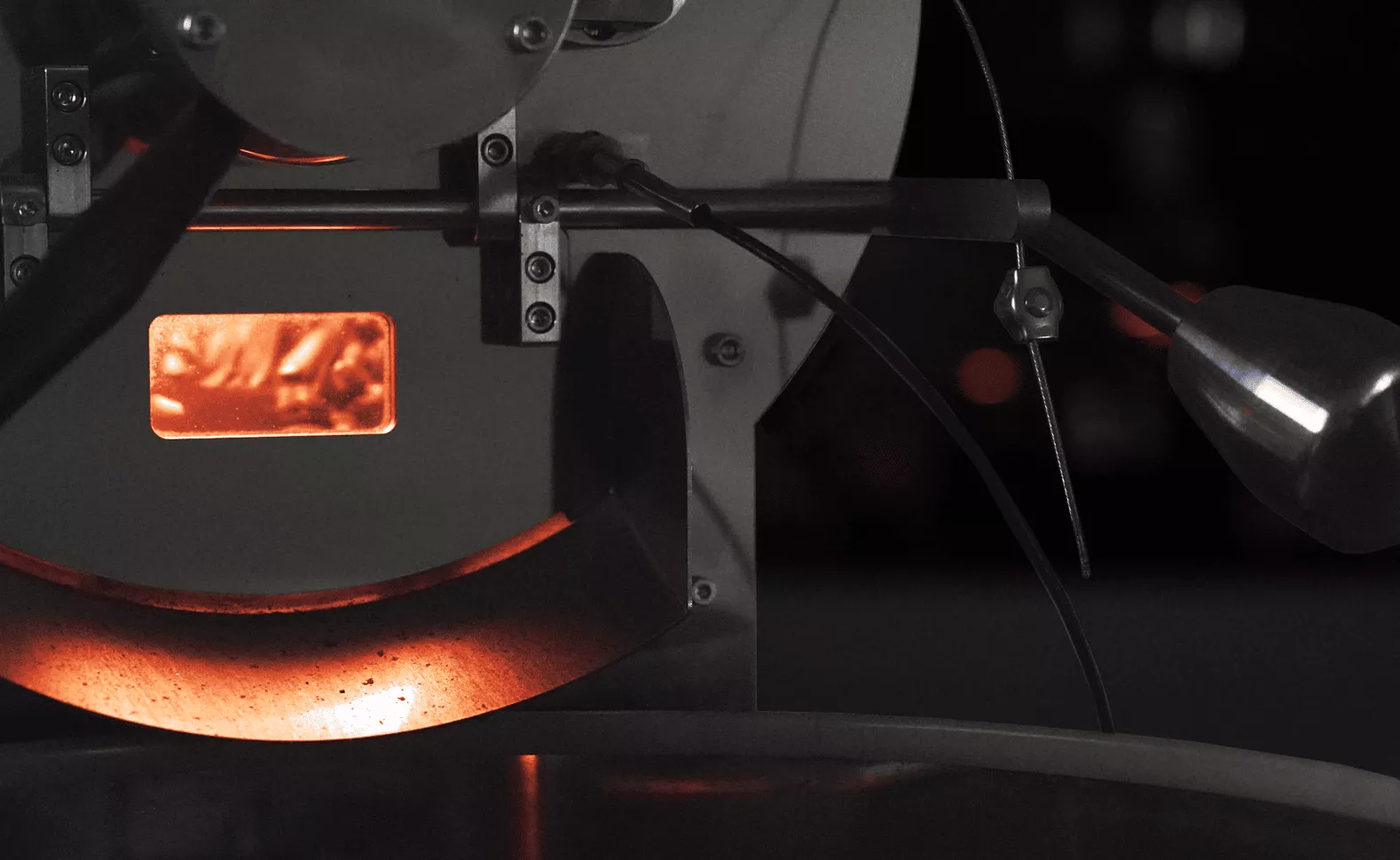

Near infrared (NIR) radiation is selected as the type of radiant heat on all Rubasse roasters due to its ability to be better absorbed by grains and its ultra-responsive and rapid heating abilities (despite being an electrical roaster which is traditionally linked with steady but sluggish heating). By placing the NIR heating element at the center of the drum and designing the roasting drum and airflow accordingly, we tremendously improved energy efficiency during coffee roasting when compared to traditional gas roasters.

Radiation roasting allows Rubasse roasters can easily roast their coffee beans evenly. This will highlight coffee flavor being more clean, clear, and vibrant.

One of the most important aspects when designing a NIR-based heating element is the selection of NIR wavelength. Rubasse roasters all have an NIR heating lamp that emits radiation energy having wavelengths between 750 nm to 1500 nm. Infrared energy lying in this area had been proven to be better absorbed by grain products (Zhongli, 2010).

▼ Patented Heating Technology

By altering the input wattage, users can achieve precise heat power control (%). However, steady heat supply is a challenge on traditional gas roasters. Several reasons would influence gas burning, such as humidity and …etc.

Ultra Responsive Power Control

The near-infrared heating applies heat quickly. It only takes 3 seconds to react to the coffee beans. In contrast, a conventional coffee roaster takes over 1 minute to heat up.

-

Differences in heat sources between Rubasse and other coffee roasters

Heat penetration and responsiveness

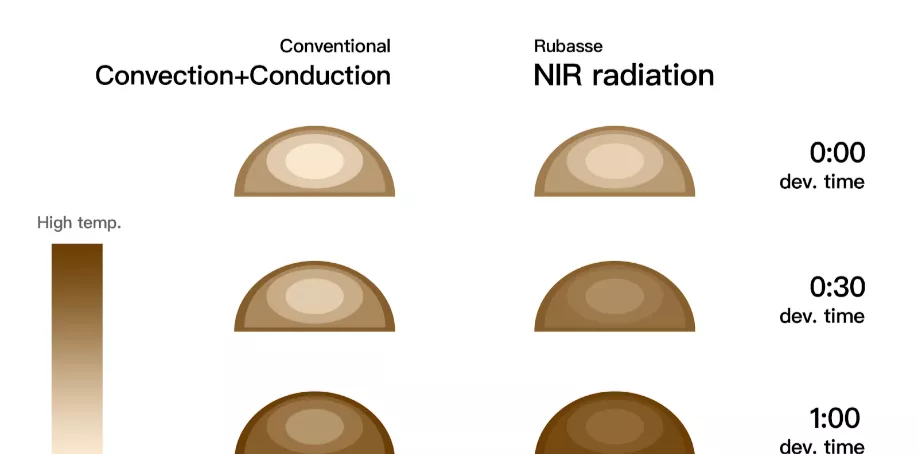

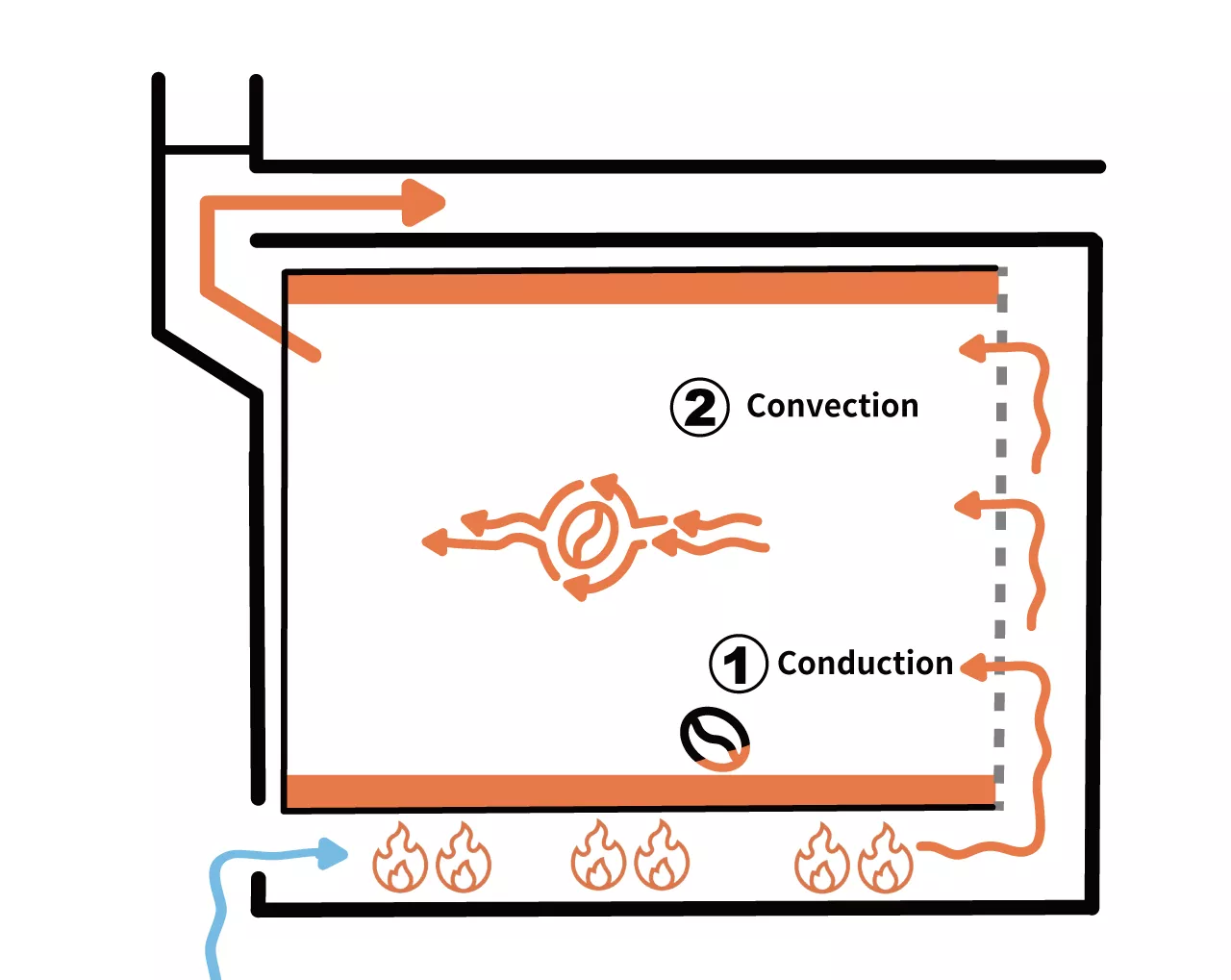

Conventional coffee roasters

Drums must be heated first, and coffee beans are roasted through conductive and convective heat. Heat must be transmitted layer by layer to the core of the coffee beans. There is no radiant heat, and the heating is not responsive and difficult to control.

-

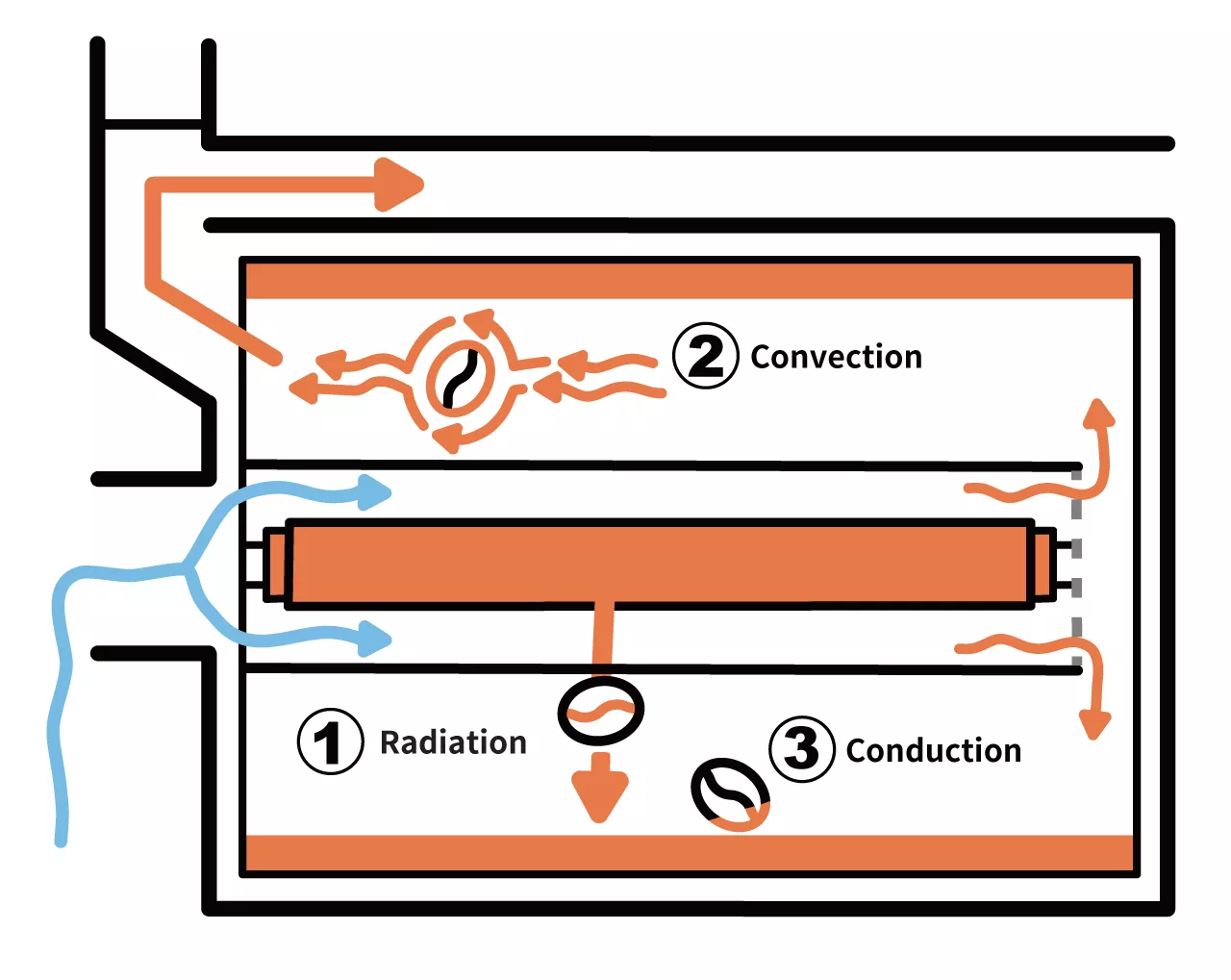

Rubasse Roasters

The world's first near-infrared center heating, using convective heat, conductive heat, and radiant heat to roast coffee. The unique radiant heat can penetrate up to 1 cm of coffee beans, allowing the surface and core of the coffee beans to be heated evenly and simultaneously, with an extremely fast heating response speed. The heat source is at the axis of the drum, directly using radiant heat to heat the coffee beans, with a fast response speed. Radiant heat can heat the surface and core of the coffee beans simultaneously

Thermal Efficiency and the extraordinoray RoR

A common coffee roaster mainly relies on heating the drum and air to roast coffee beans, resulting in a lot of heat loss. The roasting environment temperature will rise, and gas roasters are easily affected by weather factors. In contrast, a traditional electric roaster can only achieve a maximum heating rate of 10°C/minute by roasting a full pot.

Rubasse near-infrared radiation is released from the center of the drum, and the heating source will a. Directly heat up the coffee beans, b. Reflect and then heat the coffee beans, c. Heat the drum wall, d. heat the air inside the drum, forming a optical cavity that continuously converts inside the drum. According to the second law of thermodynamics, all the heat sources will eventually transfer to the lower-temperature coffee beans. This resonance structure allows Rubasse to achieve ultra-high thermal efficiency. Roasting a full 3kg batch, the maximum RoR (rate of riase) can reach 25°C/minute.

▼Rubasse optical cavity heating system keeps all the heat sources inside the drum, achieving high thermal efficiency

Stability and controllability of the heat source.

A typical gas coffee roaster can only control the heat source by regulating the gas flow. However, the purity of gas, the proportion of propane and butane, the oxygen content in the environment, the completeness of combustion, the humidity and the atmospheric pressure in the environment cannot be precisely controlled, and indirect roasting of coffee beans through heating the boiler not only wastes energy but also makes it difficult to control the coffee roasting process.

Rubasse near-infrared heat source design only requires controlling the electrical power to control the heat source. The heating halogen is located at the axis of the drum, and the radiant heat directly heats up the coffee beans, allowing for very precise control of the heat output.

Safety of the heat source.

Conventional gas roasters use gas as fuel and can pose risks such as incomplete gas combustion, carbon monoxide poisoning, gas explosions, and flash fires in poor roasting environments with excessive dust. In contrast, the Rubasse coffee roaster uses electricity as its heat source, eliminating the risk of gas-related safety issues and any open flames.