The various degrees of roast is the most fundamental element of coffee flavours. Therefore, the world’s leading specialty coffee qualification, Specialty Coffee Association (SCA) qualification, Coffee Skills Programme (CSP), mainly tests how to roast the correct degrees of roast.

After you can master the various degrees of roast, the next lesson will be how to roast the diverse flavours.

( Extended reading:Basic Coffee Roasting | Light Roast, Medium Roast & Medium-Dark Roast )

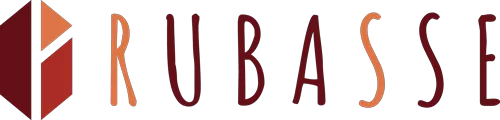

From the direct fire type, half hot-air type, hot-air type to the infrared roaster, each roaster has its own heat conduct method which results in a variety of roasts flavours.

For example:

1.The heat convection of the well-known hot-air roaster, PROBAT, from Germany and LORING from the U.S.

Relies on the hot air evenly covering every single bean. As for the flavour clarity, it is literally impeccable and is also exactly what many roasters are in pursuit of.

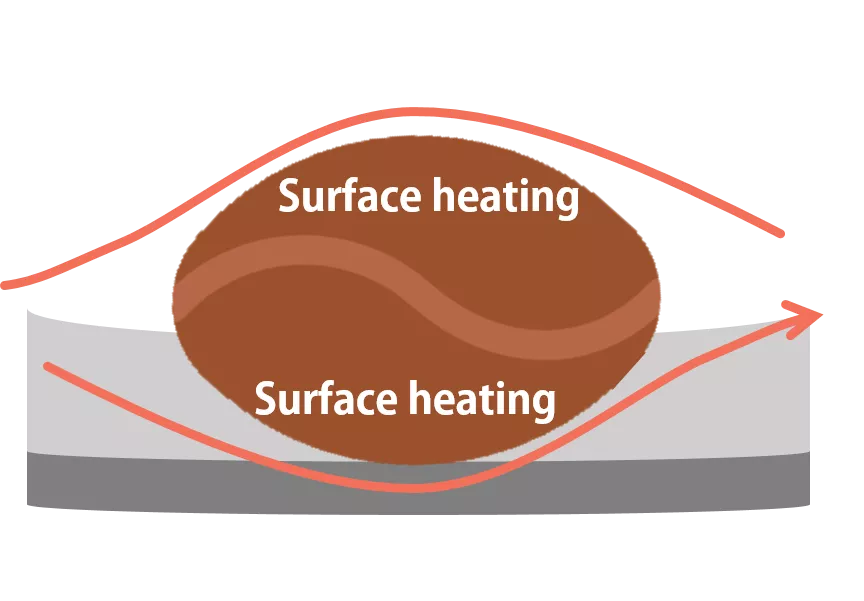

2.Direct fire type and half hot-air type roaster

Heat conduction is taken as the heating method. The beans are heated up by directly contacting the drum, so there will be a bigger temperature difference between the core and the surface of the bean.

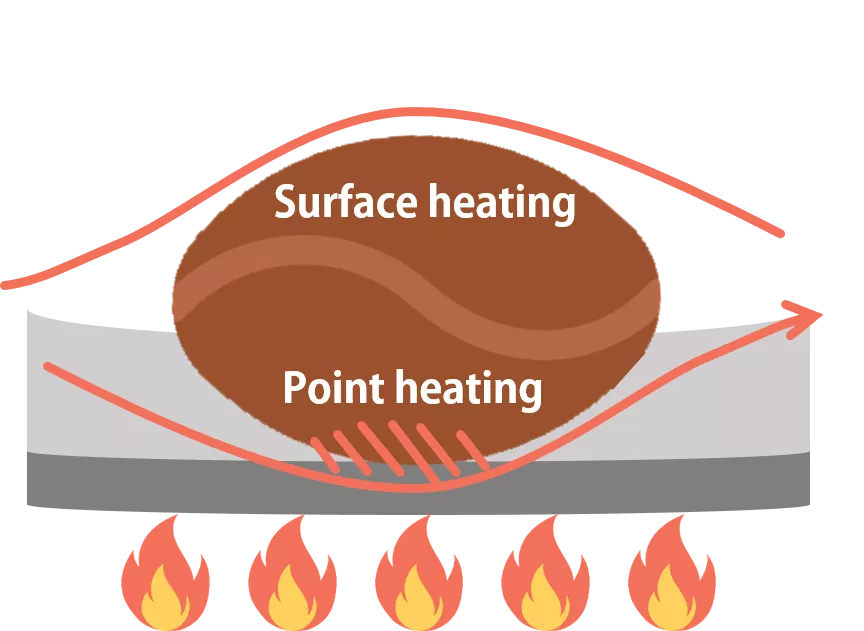

3.Rubasse’s shortwave Near-infrared roasting technology

The shortwave infrared can evenly radiate and penetrate every single bean and create the flavours with high degree of clarity.

Except for the basic degree differences of roast, light, medium and dark, there are also bean core and surface roasting degree difference which makes the layers (colour difference).

Devided into:

High clarity & high uniformity

Looking at the section of the bean, if there is no much colour difference between the core and the surface, it means the beans are uniformly roasted and the flavour is relatively pure, such as the fruity flavour of light roast and the bittersweet taste of dark roast.

Multilayered

Looking at the section of the bean, if there is big colour difference between the inner and outer, it means the roasting degree varies. Therefore, for the flavour, you may taste the coffee with the complex flavour of light roast and dark roast, such as the Nordic style roasting; you can taste the fruity aroma from the light roast with the mellowness fragrance coming from the medium roast.

However, due to the different roasting degrees between the core and surface, if it is lightly roasted, the bean surface will look roasted but the core is actually not roasted yet. Then, there is a risk of getting the unroasted (grassy taste) coffee. Besides, the difference makes the core contains more water inside which causes the continual chemical reactions leading to the quick flavour changes. It is not easy to make it taste consistent.

No matter you prefer pure flavour or the flavour with more layers, it all depends on your preference and the applications of techniques.

After knowing the above two differences, are you eager to try it out? Then, how to create the two different ways of roast?

Learn the differences caused by techniques from a scientific point of view

From the principle of physics- heat transfer:

1. Heating by hot air, infrared radiation, etc are all highly uniform heating method so the flavour tends to be relatively pure.

2. The heating method of ‘contact conduction’ through the drum is to let the high-temperature drum contact the bean surface, and slowly transfer the heat to the bean core. The bean surface will be cooked first before the core, and the flavour will definitely be more layered.

It takes time to transmit the heat from the bean surface to the core so the roasting speed will be one of the most important factors to the layers:

1. Fast roasting: The faster the roasting speed is, the shorter the time it takes. Therefore, when the bean surface is cooked first, and the bean core is not, the taste will be multilayered .

2. Slow roasting: Conversely, if more time is given to allow heat to be transferred to the core even by simmering to even the heat distribution. The slower the roasting speed is; the higher the uniformity is; the higher the purity is.

After understanding the two basic factors, we can apply the principles of heat transmission and roasting speed to create different flavours:

1. Hot-air type roaster: Although there are not many heat contact points, the multilayered flavour can be created through the fast roasting technique. Taking Loring roaster as an instance, beans can be fully cooked within as fast as three minutes.

2. Traditional half hot air, direct fire: Simmering over low heat and turning down the damper facilitate the hot air conduction, and thus increase the uniformity and purity.

3. Traditional half hot air, direct fire: Increasing the layers of flavour by roasting with higher temperature and strong hot air in the iron pot.

4. Infrared roaster: High purity and high-uniformity can be achieved by infrared radiation heating technology.

Now, you probably have a query like: ‘Now that the infrared penetration heating technology has such a great feature of penetration, is it able to roast the multilayered beans?

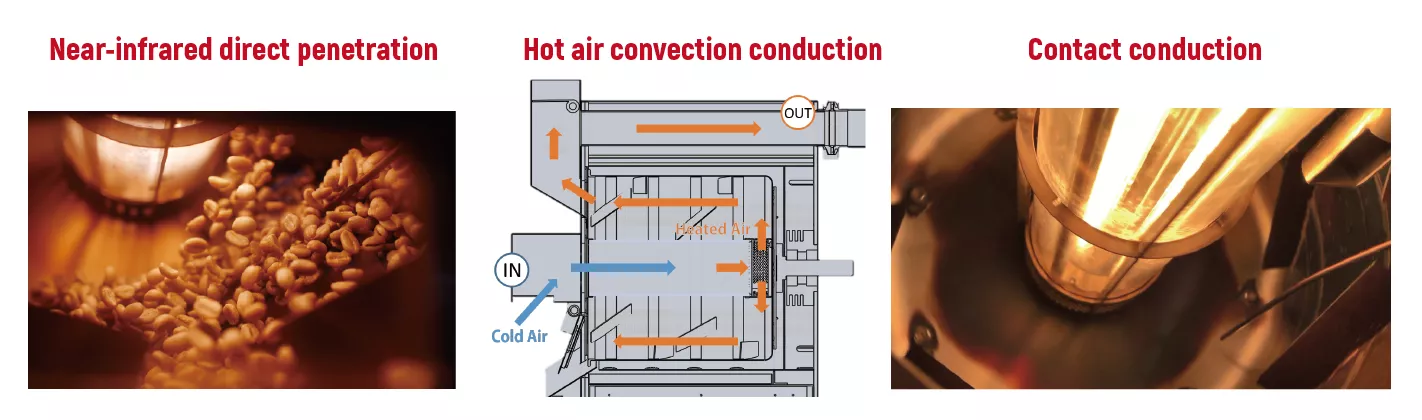

Rubasse digital infrared roaster has three main types of heating methods:

- Heating by shortwave Near-infrared direct irradiation and penetration: please find for more information 17 key points to Consider Before Purchasing your First Coffee roaster

- Hot air convection conduction: The main design concept of Rubasse convective exhaust system is that: the cold air passes through the glass tube in the centre part to cool down the heated infrared lamp and the cold air will therefore turn into hot air. The hot air spreads from the end of the glass tube to the drum and finally is exacted away from the front end. In addition to the complete utilisation of all the heat generated by the lamp, the heat dissipation also extends the life of the lamp. More importantly, through the adjustment of the fire and the damper, we can control the proportion of the hot air in the heat energy

- Contact conduction:

1.Conduct the heat through the glass tube in the centre: Because the infrared needs to penetrate the glass tube in the lamp to irradiate the beans, the glass tube will be heated to high-temperature condition.

2.Heat conduction through drum: Because the entire drum is a confined space, infrared rays cannot penetrate the iron pot.

Except for heating the beans through infrared irradiation and penetration, the remaining infrared will irradiate the iron pot and thus heat up the pot at the same time. If it reflects by the iron pot and repeatedly irradiates the beans or the pot until the infrared radiation is fully absorbed, eventually, the iron pot of Rubasse roaster will be burning hot so there will be a lot of contact heat.

Through the adjustments of the fire and the rotation speed of the drum, the proportion of he heat conduction can be controlled.

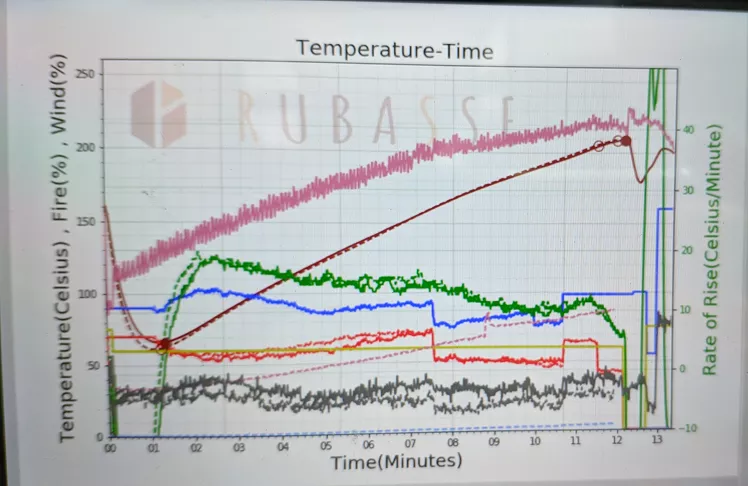

(Installing the infrared temperature probe on the Rubasse roaster can measure the temperature of the boiler surface (the pink curve). During the roasting process, the drum the temperature increases about 50℃ from the beginning and it is nearly the same as the others.)

Through regulating the damper to control the convection proportion, adjusting the drum rotation speed to control the contact heat proportion and adjusting the roasting time to control the heat conduction to the bean core, Rubasse roaster is capable of creating the diversity of flavours no matter for multilayered or high purity flavour.

( Exdended reading:北歐快烘手法│「DYC咖啡」分享 (Still in translation progress) )

Multi-layered roasting

- Drum with low-speed rotation: increase the heat conduct proportion

- Exhaust with low-speed rotation: multi-layered roasting technique.

- Fast roasting: to create and facilitate the differences between layers.

- Turn down the damper: to reduce the convection proportion.

High uniformity roasting

- Drum with high-speed rotation: to cut down the radiation proportion of infrared.

- Exhaust with high-speed rotation: high purity roasting technique.

- Low roasting: to create and facilitate purity, fragrance and sweetness.

- Turn up the damper: to increase the convection proportion.

Sharing of Multi-layered Roasting Technique by Users

Generally speaking, roasting techniques are roasters’ creation with lots of efforts and are also their trade secret.

We invited the special guest roaster, Sam, to share his high-multilayered flavour creation experience. Sam is a very experienced roaster with more than one-ton production every month.

Sam:

During each roast, it is important to present the nature and specialty of its growing background of the raw beans through different techniques. The common-seen fast roasting and slow roasting ( according to the total roasting time), degrees of roast (light, medium and dark) and the choice of roaster are the keys.

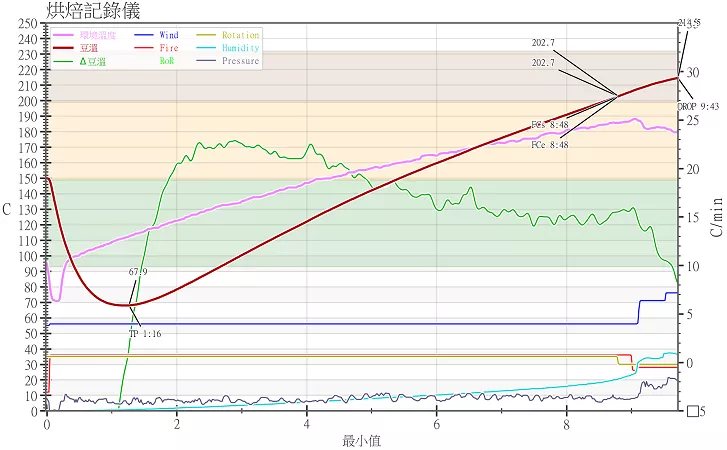

This time, Rubasse Digital Infrared Roaster was used to roast Yirgacheffe 500g. The total roasting time was about 10 minutes which ended when the temperature reached 215 ℃ and cooled down within 2 minutes. During the dehydration and Maillard reaction period, the same parameters were applied until the first crack. As entering the first crack, adjustments were made to control the development period within 1 minute.

When entering the first crack in intensity, turn up the damper to let the steam which was emitted from the first crack go off and turn down fire to quickly slow down the ROR. Here, I would like to share a tip for increasing the roasting degree of the bean surface. When I was conceiving the roast, I hope the beans can absorb more contact heat of the drum by slowing down the rotation speed to 30 RPM at the first crack and increasing the contact time of beans and the drum. (Please refer to the following curve chart for the above technique)

Parameter setting:

1. Roaster used: 3kg Runasse Infrad Digital Roaster

2. Weight: 500g

3. Charging temperature: 150℃ (low temp. charging)

4. Roasting technique: fix the exhaust, fire and rotation speed the First crack and then decrease the fire, increase the exhaust and slow down rotation speed.

5. Total roasting time: 9 minutes 43 seconds

6. Discharge temperature: 214.5 ℃

We tried to minimise the cumbersome operation through the above roasting technique. The roasted beans are measured Agtron: 65.5 with CM-100 and the Coffee power is measured Agtron 82.9. Through the simple calculation, we can find that the Agtron number difference between beans and powder is 17.4, which is a good result.

For the electric roasters, it seems mistaken by many people that the tastes it makes tend to be lack of ‘layers’

This is also the doubt raised by many people in the field. However, through the practical operation, it can be seen that the speed, damper and firepower of the drum on the roaster are adjustable. It is not difficult to roast with diverse techniques only if you are willing to practise with your beans.

Instead, as the roaster is too adjustable, you might have no idea how to get it start. As for the creation of multi-layered flavour, except for the subjective cupping, the most common and objective method of testing is to use scientific elements to detect. From 100 degrees to the end of roasting, take samples every 10 degrees, then take a section shot to observe the profile state at each stage.

Surprisingly, as can be seen in the first picture below, when the temperature is 170℃, the Maillard reaction is intense, and the effect of heating by infrared radiation penetration is remarkable. The deepest layer is thought to be like the colour of the unripe coffee germ but it is actually darker compared with the green bean core. The lighter layer in the middle, during the roasting process, the profile of the coffee beans (see the following second picture), also turned into a darker brown colour which makes us relate to the beautiful Caramelization reaction.

(PS: The brewing and cupping result shows the rich sweetness with the fragrance of orange peel, tangerine peel along with oolong tea fragrance, rich in layers and flavours.)

(Sample of coffee beans at 170℃)

(Sample of the roasted coffee beans)

When I firstly contact with the Rubasse infrared digital roaster, I used to have doubts about its firepower and its potential to create multi-layered flavour. Until the actual operation, I found that it is highly flexible and the ROR control is also accurate and intuitive. Thanks to my curiosity with some challenge-taking motivation, I did not miss this effective and convenient roaster.

Of course, each model has its pros and cons. Below is how I feel about the flavours created by each type of roaster. For example, the direct fire type tends to be mellow and rustic, the half hot air type tends to be more fragrant, the hot air type tends to be pure and fresh, and Rubasse infrared digital roaster combines all the characteristics of the above. The design of Rubasse allows extremely flexible functionality and adjustability which enables the roasters’ roasting concept can be realised as much as possible.

Besides, the simple operation and intuitive display enable the roaster to operate with ease and to concentrate on the adjustments of ROR, damper and fire, as well as the observation of their following reactions, which is the most impressive advantage to me.