The roasting curve is useless. Yes, no need to go back and check the previous sentence, you heard us right.

Well maybe not, we probably exaggerated it a little bit too much, but ask yourself: how many times did two roast batches with very similar (some would even claim “identical”) roasting curves turned out to be tasting……well……anything but identical?

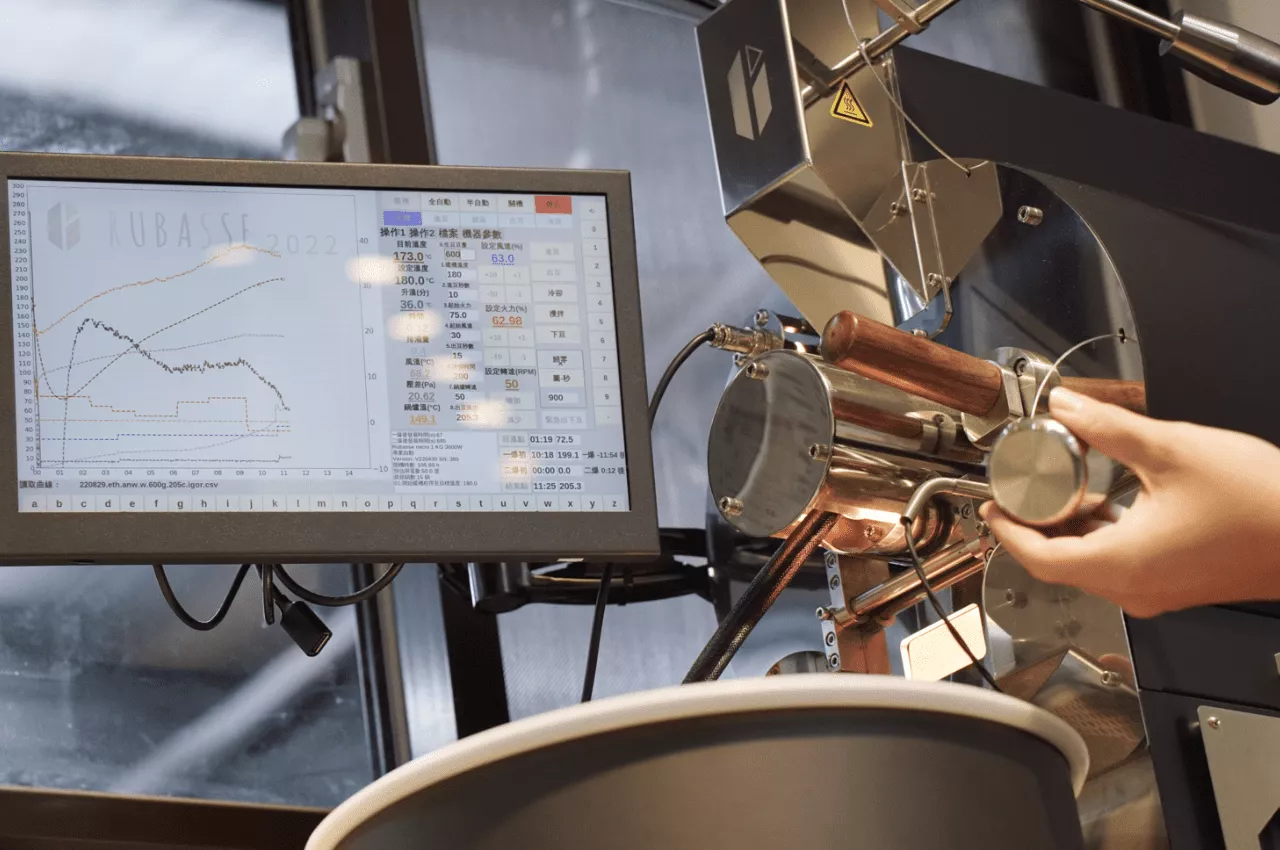

Back in earlier days, we did run into these kinds of situations now and then, but after countless hours doing research and development, now when we experiment with coffee roasting using our Rubasse Micro roasters, we do not only record the commonly seen bean temperature curve. Our extra sensing devices on our roasters nowadays keeps track of:

-

Outlet airflow temperature

-

Drum inner-surface temperature

-

Pressure difference between the roast chamber and environment

-

Exhaust airflow moisture content (which is then calculated using our own researched formula and displayed as amount of water content vaporized)

When the roast results don't come out as expected, although the frustration (and the post-cupping depression) still exists, we can now do our post-roast troubleshooting much faster and with more insight compared to the days when we only had a bean temperature thermocouple.

Besides troubleshooting, having more roasting variables under close monitoring may give us a better chance to have a peek at the “truth” of coffee roasting. Utilizing the sensors on our roaster, we can gain some of the following benefits:

-

Have an idea about the difference in green bean initial water content (you probably still don’t have a moisture meter, and good news, you probably can live without one if you roast using one of the Micro series roasters!)

-

Know the “actual” airflow while roasting (and you can control it easily by keeping an eye on the differential pressure sensor)

-

Obtain indicators regarding the different methods of heat transfer during roasting, i.e. the drum temperature and the exhaust air temperature can give you overall ideas about the conduction and convection heating during your roast

-

Monitor the roasting environment with much better precision, drastically decreasing the chance of having an unexpected “runaway roast” with a disastrous outcome (and probably unpalatable coffee)

However, these accurate sensing tech devices are only half of the story.

Imagine this: you now have all of the most advanced sensing tech gadgets installed, but every time you try to make some heat adjustment according to the data you obtained, you couldn’t really accurately control the gas valve to be exactly where you want it to be. Yeah I know, I personally experienced similar frustrations numerous times before. So when I first started using the Micro roasters, I quickly found that the fully digitalized control over all roasting variables (heat application, exhaust fan speed, drum speed…etc) actually have helped me to experiment and learn much faster. The precise control and ample data collected by the roaster combined with sensory feedback and cupping experience really opened up a whole new dimension of playing around with flavors and roasting for me.

With all that being said, if you are now interested in knowing more about the roaster mentioned above or even personally trying out one of the Rubasse Micro roasters, feel free to shoot us a message using the form below and start experimenting and creating excellent coffee with your roasts in a even more scientific manner!!