Contents

-

Radiation roasting: Why and how its done

-

Test roasting: The Yirgacheffe natural “runaway” profile

-

Takeaways

Conduction, convection, and radiation. Anyone trying to learn coffee roasting probably already stumbled across numerous contents about how these three different methods of heat transfer are utilized during coffee roasting. Once having gone through one or two blog posts or some forum discussions, one should quickly notice that the majority of these contents are focused on “conduction v.s. convection”, “the best way to maximize convection on a certain brand/kind/model of roaster”...etc. Through all this time, although it might be occasionally mentioned here and there, radiation seems to always be the one that's left out of the spotlight.

Not anymore.

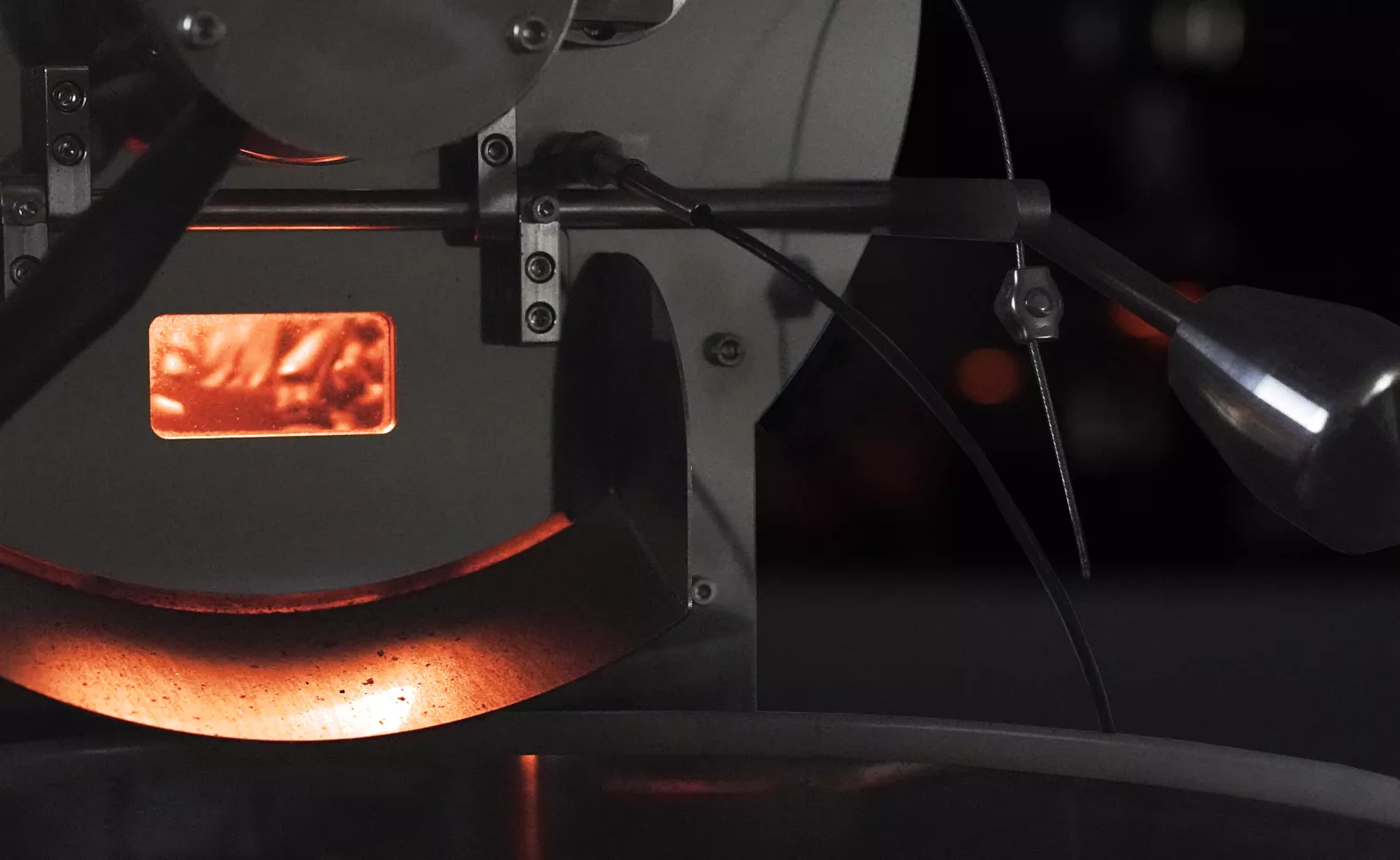

Here at Rubasse, we actually design and manufacture fully automatic shop roasters that use center-placed near infrared radiation as the single roasting heat source. As we see it, using radiation really is an efficient, exciting, and overall wonderful way to roast coffee - here’s why.

Radiation roasting: Why and how its done

Radiation is the only method of heat transfer that is penetrative in nature, and this is one of the main reasons that we think it is probably the most suitable for roasting coffee. Why?

Well, though the “sear and grill” technique might give you excellent pork chops, for coffee, what we really want is adequate and sufficient heat applied as evenly as possible; While most can appreciate and enjoy the seared crust on the outside of a grilled steak, “searing” coffee would only add annoying harshness and bitterness to the cup, resulting in unbalanced or even unpalatable coffee.

This is where penetrative radiation heating really gets its chance to shine. Ideally, by using radiation as the main heat source of roasting, we could reap its benefit and get more evenly roasted beans, avoiding over-developing the surface and/or under-developing the inner.

However, that is easier said than done.

To design a roaster based on radiation heating, one needs to come up with a roaster design that allows efficient use of the radiant energy, select the correct type of radiation and suitable heating elements, and combine all things together and make sure it roasts as you wanted. The result: the world’s first near infrared (NIR) digital coffee roaster.

Below are some of the important design features and its benefits:

-

Near infrared (NIR) radiation is selected as the type of radiant heat on all Rubasse roasters due to its ability to be better absorbed by grains and its ultra-responsive and rapid heating abilities (despite being an electrical roaster which is traditionally linked with steady but sluggish heating).

-

By placing the NIR heating element at the center of the drum and designing the roasting drum and airflow accordingly, we tremendously improved energy efficiency during coffee roasting when compared to traditional gas roasters. (We have planned to release updated consumption testing results and more details regarding energy usage later this year. Please stay tuned if interested.)

Test roasting: The Yirgacheffe natural “runaway” profile

We have now talked the talk about roasting with NIR radiation, and the time has come for us to actually walk the walk. Afterall, just like most theories and new inventions in coffee, what really matters is the ability to produce real world results that cater to the palate of we coffee drinkers.

Here, we especially want to share one particular roast we have done on our roaster. Although we also roast “normal” roast profile coffees on a daily basis, we kept hearing our R&D team talking about a “forbidden profile”, which (allegedly) represents “the essence of near infrared roasting”. So not long ago, we finally tried it out. The results are shared below:

Green coffee information:

-

Origin: Gedeb, Yirgacheffe, Ethiopia

-

Producer: Wote Konga washing station

-

Variety: Heirloom

-

Grade: G1

-

Processing: Natural

(The Wote Konga natural Heirloom before and after roasting)

Roast profile overview:

-

Charging ¼ of full capacity

-

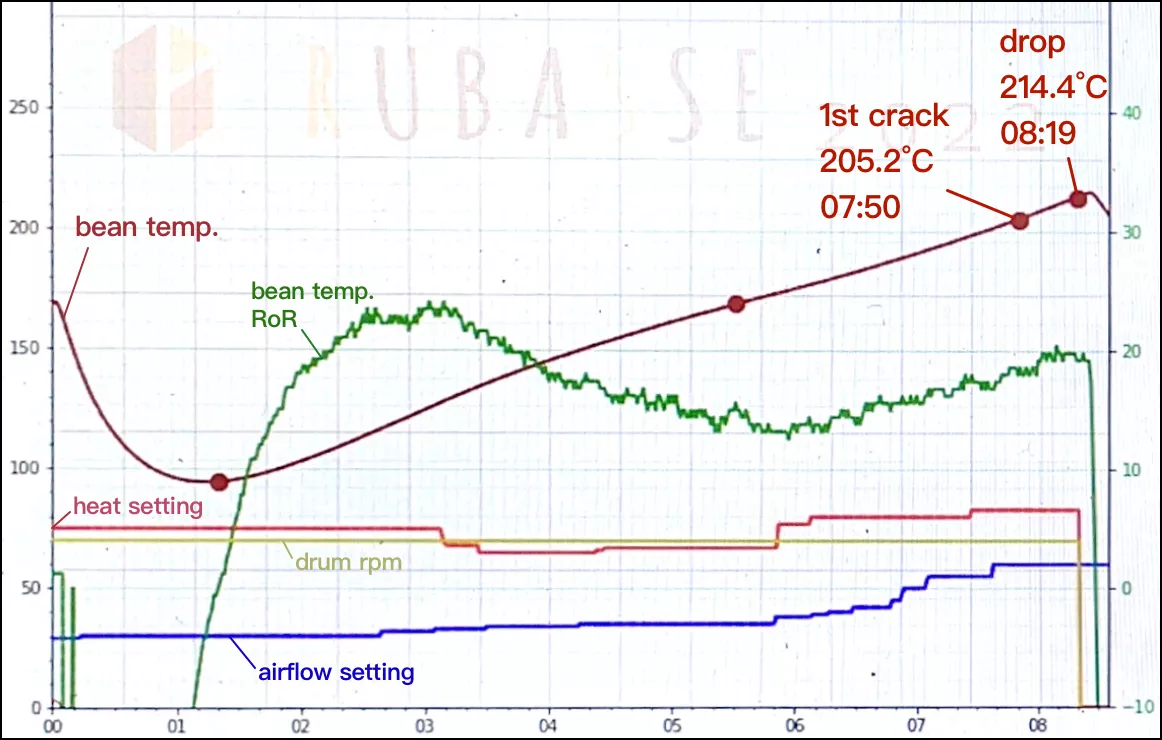

Bringing the batch to 1st crack at around 8:00

-

Time from 1st crack to drop: around 30 seconds

-

Enter 1st crack with a 18-20°C/min rate of rise

-

Dramatically increase the amount of airflow towards the end of the roast

-

For those who measure roast color, the final product reads 77.2 / 90.7 (whole bean / ground) on the Agtron color scale.

Ok, we know that under conventional coffee roasting wisdom, this profile is screaming “trash coffee” that’s probably ashy, burnt on the outside, and very underdeveloped on the inside.

But the truth is, this is actually a quite enjoyable cup starting from day 1 after roast.

Sensory notes:

Cupping right after roasting, we find white florals, blueberries, peach-like fruitiness, and rich toffee flavors along with a smooth medium body and almost velvety texture. Of course, the mouthfeel is interrupted by some gassy sensations since it's freshly roasted, and some hints of caramel popcorn-like flavors make us start to think that the roast might be underdeveloped a bit.

But after 7 days of rest, we cupped the coffee again. This time not only the popcorn-like flavors disappeared, the cup is actually very vibrant, the flavors are defined, and the body is full, round, but also very clean. Some tropical fruit notes also appeared. One of our team members (who is a certified Q grader) even insists that the floral aroma is so defined that it “smells exactly like my lily of the valley scented candle”.

That sure does sound like an interesting cup.

Discussions:

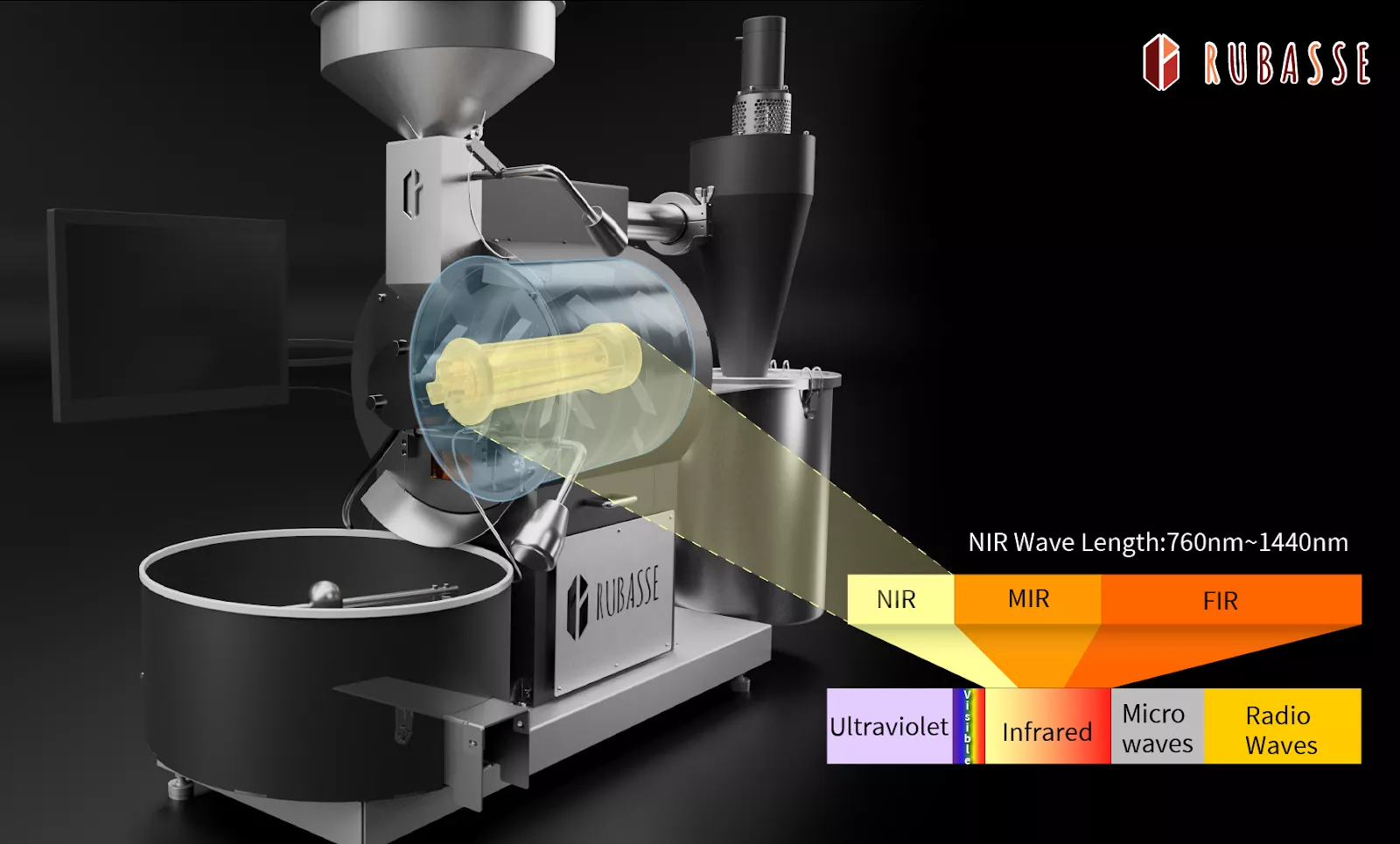

From the roast profile, we can see that the main difference is that we actually continuously increased the heat setting towards the end of the roast. At the same time we also increased the airflow setting all the way up to 60 (For reference: normally for a similar batch size, the airflow setting would be around 30~34).

The reasoning behind these operations is to maximize the proportion of radiation heat transfer towards the end of the roast (hence “the essence of NIR roasting”). By increasing airflow to an almost ridiculous amount, we are trying to lower the overall temperature of both the airflow itself and the metal drum. On a common drum roaster, this probably looks like a guaranteed recipe for disaster, but since the center-placed NIR radiation heating element is working at almost max output and pumping heaps of radiant energy onto the coffee beans, we actually can still develop the coffee well enough using mainly radiation (and obtaining high RoR values towards the end of roast as shown on the profile).

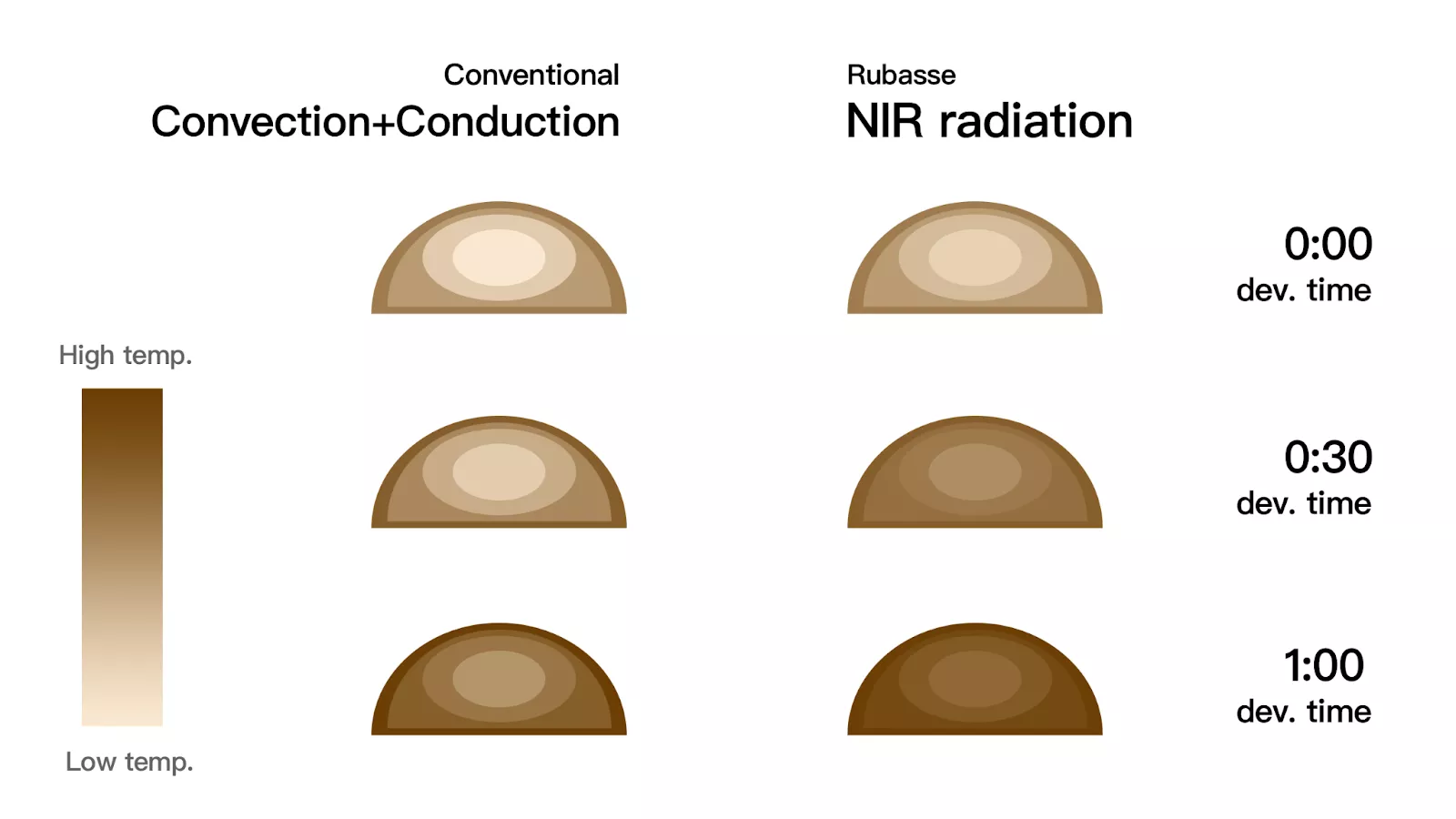

Also, some of the readers might already notice that the time after 1st crack to drop (or what’s usually called “development time”) is relatively quite short. The reason behind this also links back to the use of radiant energy for roasting. Put simply: What the traditional convective and conductive heat transfer can do in a certain amount of time, radiant heat transfer can obtain similar results in a shorter duration (mainly due to its penetrative nature). The graph below is here to further illustrate the reasoning behind this idea.

(Note: Although the numbers are taken and modified from the results of several studies, here they are only presented for illustrative purposes.)

As shown on the graph, under the two different kinds of heat application, when the beans reach similar surface temperatures at identical timings, their inner temperature can actually vary. The inner bean temperature “catches up” faster with the surface temperature when the heat applied is mostly in the form of radiation.

The implication is that coffee beans could be roasted to a level that is considered “done” in a shorter period under radiation roasting. This probably is the reason why this Yirgacheffe natural can have an unconventionally short development time yet not bearing any underdeveloped green/grassy/raw-nutty flavor notes.

This characteristic of NIR radiation roasting not only allows roasters to worry less about underdeveloping the coffee they are roasting, but also opens up new possibilities when fine-tuning the balance between flavor, acidity, and body. For this particular green coffee used in our test roasting, though our previous, more conventional approach also yielded good results, but without doubt it’s the seemingly reckless “runaway” profile that gave us a much more stunning cup and deeper insights into the potential that this coffee might have packed.

Lastly, another point worth mentioning is that when designing this profile, we intentionally sped up drum rotation. This is to help the batch of coffee “spread out” better and be more evenly exposed to the radiation emanating from the center-placed NIR heating element, hoping to maximize the possible benefits of a radiation-driven roast.

Takeaways

Due to its penetrative nature, radiation roasting enables roasters to apply heat to both the outer and the inner of the coffee bean more evenly. This allows roasters to have more options and freedom when designing roast profiles that have the ability to bring out the best of each coffee or create some unique balance that truly impresses. The method of roasting demonstrated in the previous test roasting part is by no means the only way to utilize radiation when roasting, and we are also still constantly trying out new profiles and looking for new, possibly better ways to roast and express the wonderful flavors of different coffees.

So now, we would like to happily invite you to join a new era of coffee roasting. Or simply, by using the powers of radiation heating, roast better coffee.