Choosing a coffee roaster to buy could be a daunting task.

With seemingly endless options and information about a lot of those options being vague at best (you will be surprised about how little information most coffee roasting machine manufacturers are putting out)(at least online), those who want do make educated purchases could only hope to have some kind of “general guidelines” that could help them quickly decide whether one roasting machine is worth the money or not.

As a coffee roasting machine manufacturer, we couldn’t recall the numerous times people get in touch with us to ask “What is the best coffee roaster for me/my business?”

So here we try to put up a (very) condensed “coffee roasting machine buying 101” for all that is wondering “what’s the best machine for me?”

Let us carry on.

Table of Content

(Feel free to tap on and jump to the section you’re interested in)

The 20% that affects 80% of a roasting machine’s performance

The 20% that affects 80% of a roasting machine’s performance

Different Types of Coffee Roasting Machine

Different Types of Coffee Roasting Machine

General Rules

General Rules The Common Categories

The Common Categories

Outro

Outro

The 20% that affects 80% of a roasting machine’s performance

The Pareto principle: Roughly 80% of consequences come from 20% of causes.

This truly does apply to coffee roasting, even if the checklist you need to “get it done right” in order to roast good coffee seems to be endless at first glance.

For us, the “20%” of coffee roasting is, without doubt, the “heat source”.

How you apply heat on to the beans being roasted & how much control/precision you have on that heat is the most crucial aspect while roasting coffee. Period.

Starting from ancient times, human beings have developed numerous ways to apply heat to food that is cooking or things that need drying/burning/heating. While some applications still remain to have this ultimate freedom, for coffee roasting, we have converged to a handful of methods/equipment to help us get the job done.

Different Types of Coffee Roasting Machine

General Rule of Thumb

The simplest way to categorize any coffee roasting machine is by asking: "Does the roasting machine have a horizontally-placed, rotating roasting drum?"

If the answer is yes, you are dealing with a typical "drum roaster" (or a modern variant of it).

If the answer is no, you are likely working with either a "fluid bed" roaster or one of the (rare) more uncommonly configured roasting machines.

It's important to note that within the broad "drum roaster" category, several different types exist. How are these categorized? By the crucial “20%” which is the roasting heat source configuration, of course!

The Common Categories

< The Drum Roaster Category >

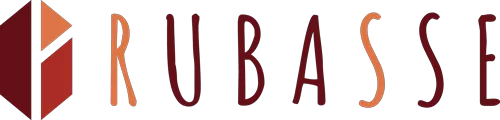

Traditional, single drum roasters

This is what most people picture in their minds when the word “coffee roasting machine” pops up.

The burner (main heat source) is located directly under the spinning metal roasting drum, and the flames from the burner may or may not be in direct contact with the drum metal.

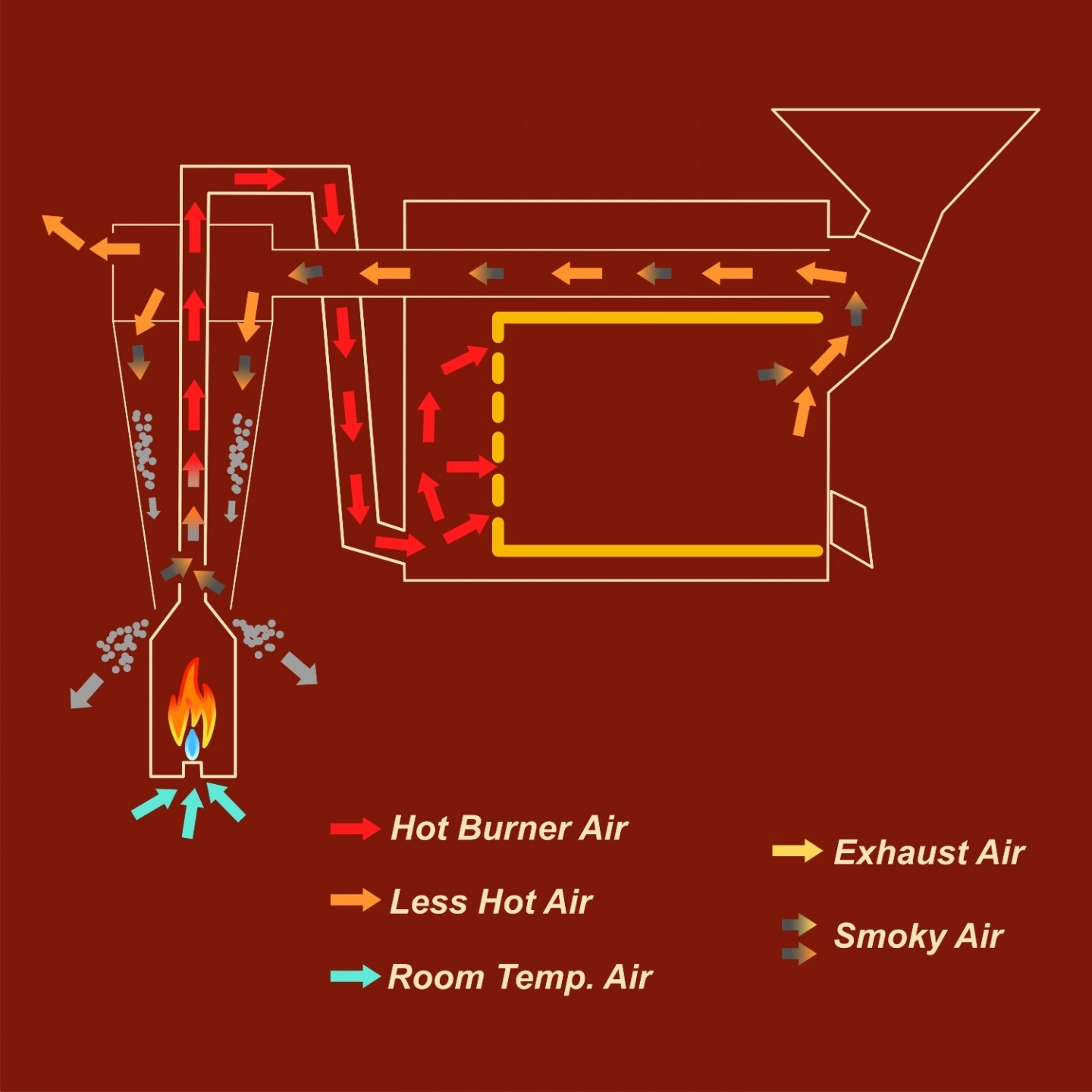

Airflow is designed to be first pulled through the burner, heated up, and drawn in from the back side of the roasting drum (the backside of the drum is usually perforated). Smoke, steam, chaff, and debris of lighter weight will be pulled out from the roasting drum by the exhaust (usually located at the front of the drum), and the exhaust air will be passed through a “cyclone” to separate the chaff, ash, and debris from the exhaust airflow.

Prominent examples of this type of machine includes: San Franciscan roasters, older models of Probat roasters, US Roaster Corp. roasters…etc.

Although the traditional single drum roaster is a time- and battle-proven design, one major issue plagues the majority of this kind of roasting machines:

The drum is easily overheated by the open flame (hence the drum is of red color in the graph), and this increases the “conductive” heat transfer ratio, making the final roasted products prone to overheating-related roast defects.

To battle this issue, manufacturers come up with the idea of the “double drum” design.

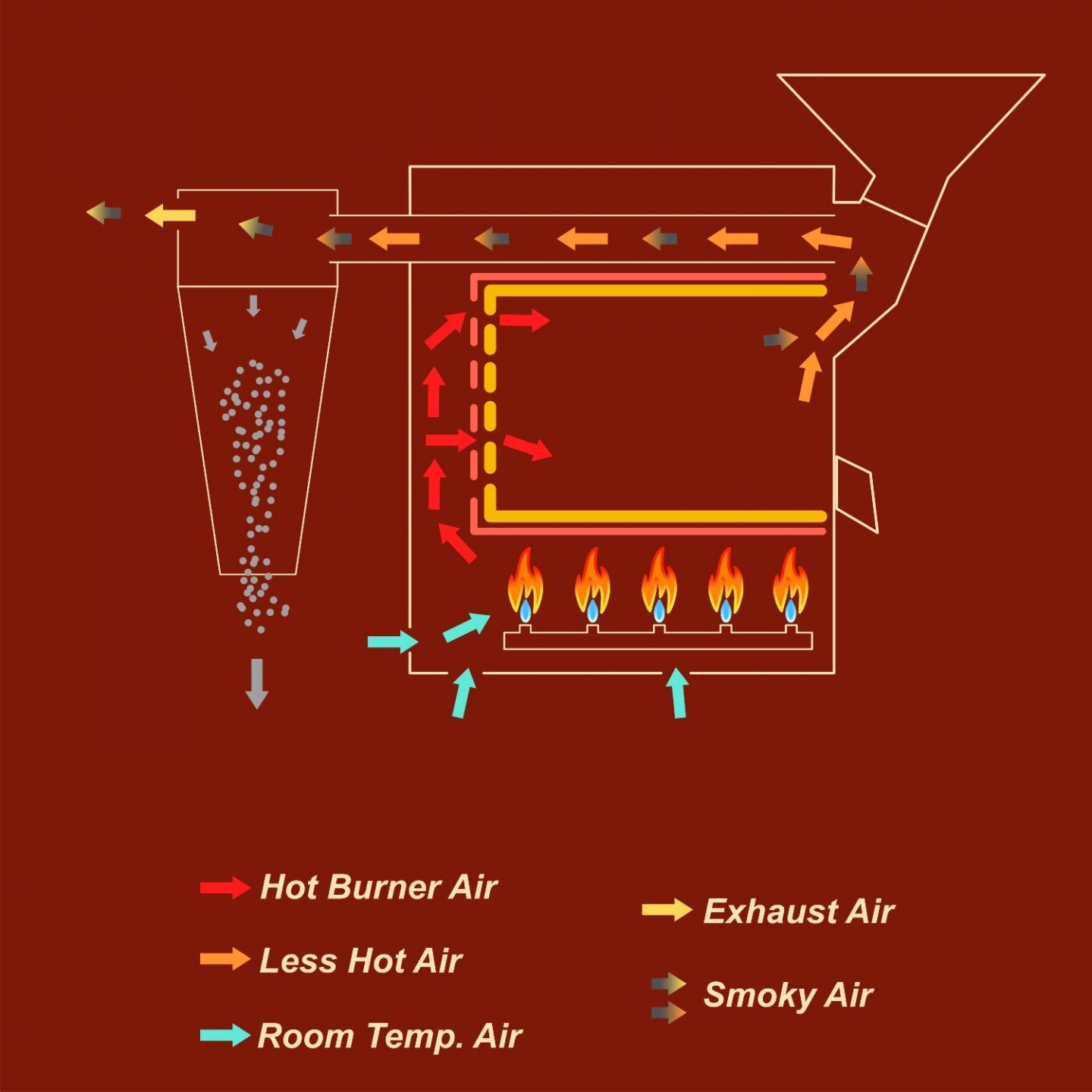

double drum roasters

The one and probably only difference between a traditional drum roaster and a double drum roaster is, as the name implies, that the double drum roaster has a rotating drum that has “two layers”.

The outer drum and the inner drum aren't in direct contact with each other, and the open flames from the burner can only touch the surface of the outer drum (hence in the graph the outer and inner drum is of red and yellow color respectively).

This effectively lowered the conduction ratio during roasting and systematically increased roast quality of the traditional drum roaster design.

However, please note that this does not mean that the double drum roaster is a “convection” roaster nor does it behave like one while roasting.

Since the whole roasting drum is still in contact directly with the burner's flame, the outer drum can still get very hot, and roasters still have to carefully control and manage the heat stored on and released from the hot metal parts during the later stages of a roast.

Examples of a “double drum” roaster includes: Giesen roasters, newer models of Probat roasters (the P series and some others), newer models of Diedrich roasters…etc.

Direct fire drum roasters (perforated drum)

This kind of roaster is another twist from the traditional drum roaster design.

The most significant difference of a direct fire drum roaster is that, instead of the backside only, now the whole drum is perforated.

This has several impact that makes a direct fire drum roaster roasts very differently from a traditional single drum roaster:

- The flames have the chance to directly contact the roasting coffee beans, and the perforated drum decreases the metal mass in contact with the bean batch. Since the “flames” are essentially gas that is heated to very high temperatures, combined with the lower mass of hot metal in contact with the beans, and we can say that direct fire drum roasters have the potential to roast with a much higher convection-conduction ratio than the traditional drum roaster. However, keep in mind that overheating of the drum metal is still an issue here.

- The distance of the burner to the drum will dictate how much of that burner flame will be in contact with the drum/roasting beans, so getting this variable right is of utmost importance if you have a direct fire drum roaster

- Chaff and debris have the chance to drop through the holes of the perforated drum and be directly combusted by the burner (as shown on the graph). This could create some (or a lot of) unwanted smoke, and may influence the flavor of the final roasted coffee.

- The direct fire design gives roasters a very agile control over the roasting process, but in the case of an unstable gas supply, also increases the uncertainty while roasting.

These characteristics make the direct fire design a kind of roasting machine that is very distinctive, and users of this kind of roaster also usually have very strong opinions about their performance.

Famous examples of “direct fire” roasting machines are: Fuji Royal “direct fire” roasters.

Also, note that some other roasting machines also uses perforated drums but doesn’t have burners directly under the roasting drum. Such examples are: Hottop roasters (electric-driven home roasters), Behmor roasters (electric-driven home roasters), Quest M3 (electric-driven home roasters), IMF roasters (perforated drum but has a totally different heating system)…etc.

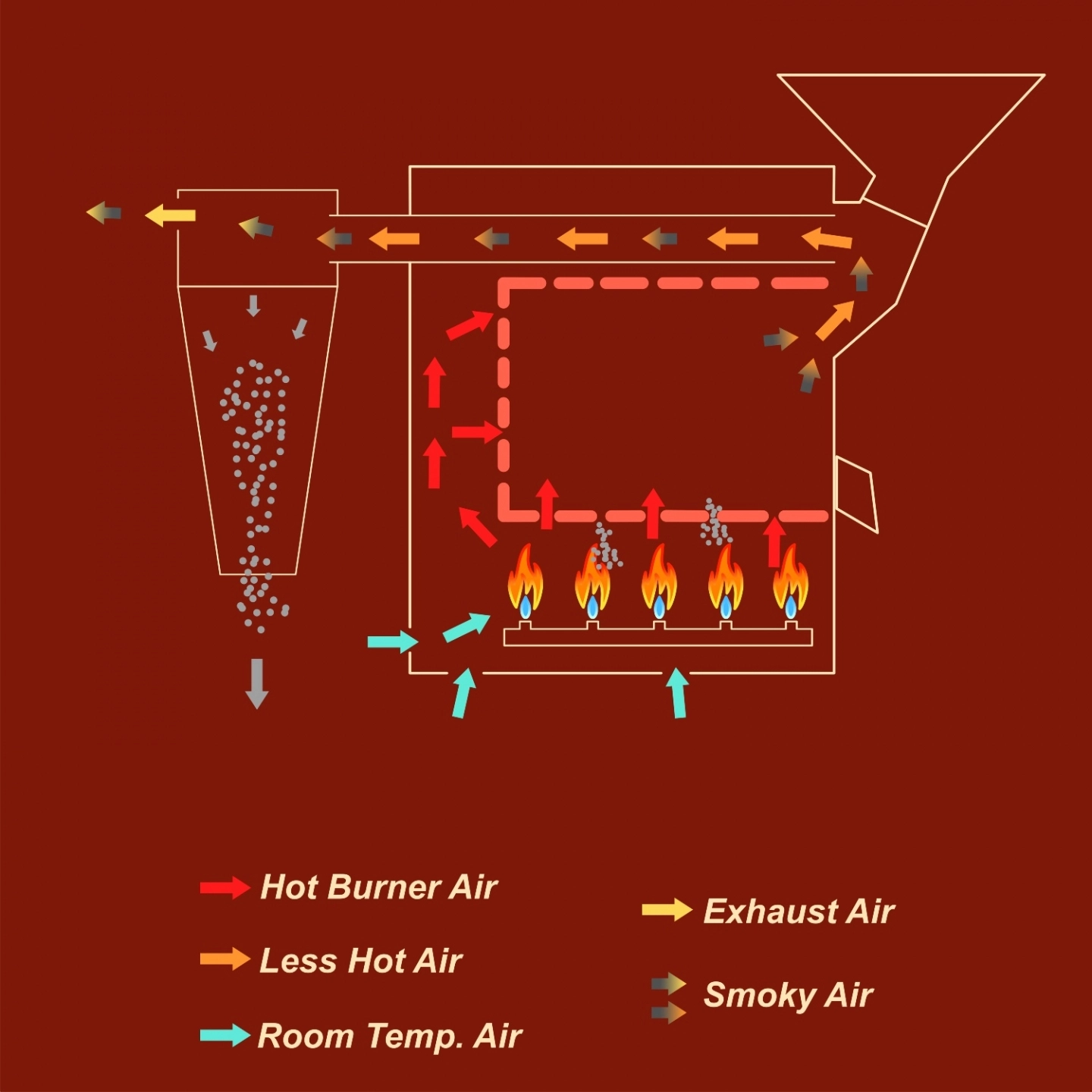

Separate burner chamber drum roasters ("hot air" drum roasters)

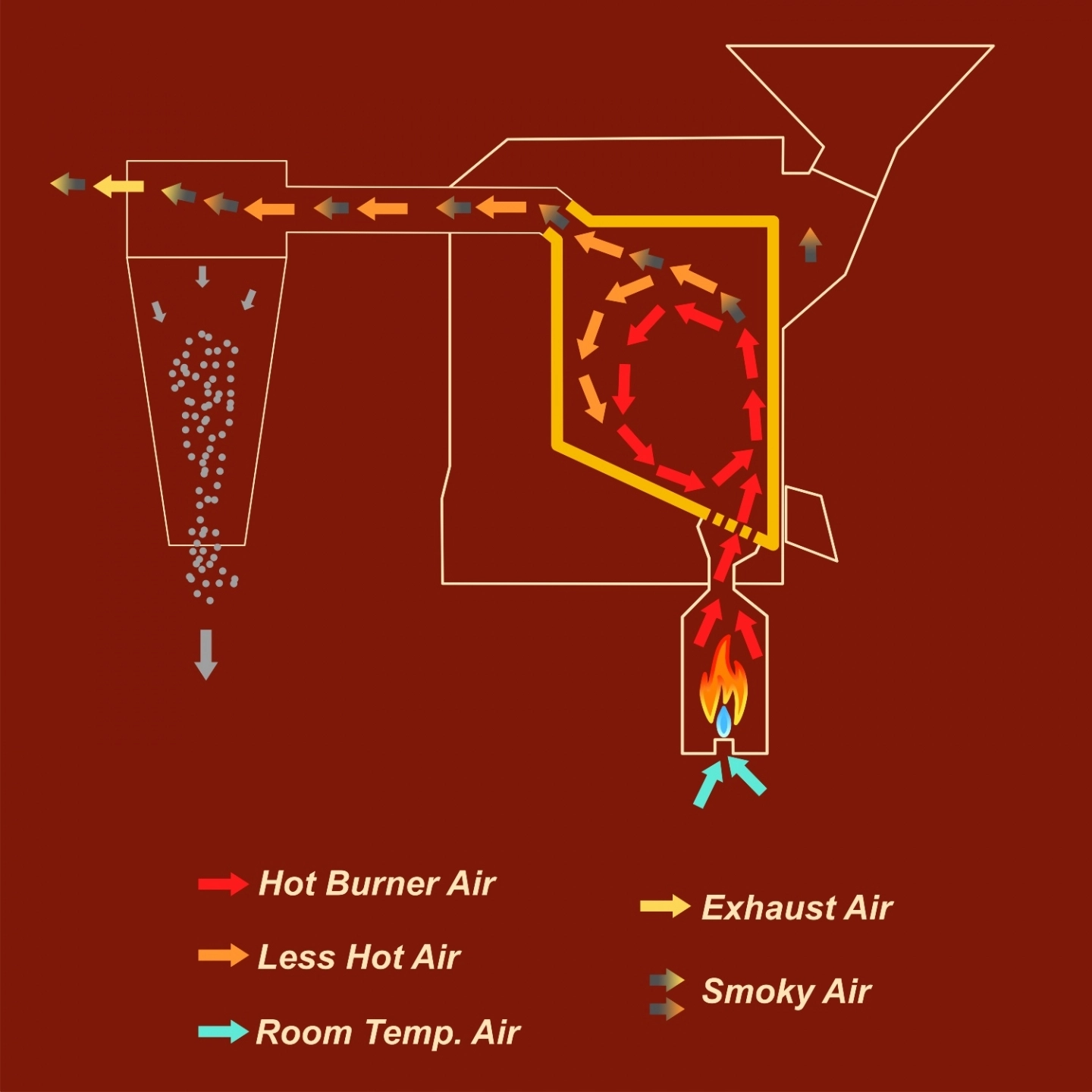

One way to solve the “overheated roasting drum” issue is to simply make the burner not be in any contact with the roasting drum.

This is largely how a separate burner chamber drum roaster works.

The burner is located in a separate “combustion” chamber, where the airflow is first drawn in and heated up. Then the heated airflow will be pulled into the “roasting chamber” where the roasting drum is located. After that, the airflow goes through a similar route as the other drum roaster configurations.

But this change in burner position did effectively and promptly solved the overheating issue, and also allowed manufacturers to start using stainless steel to make roasting drums that are lighter in weight and more durable and rust-proof over time.

However, the one downside of this design is the decrease in energy usage efficiency during roasting. This additional moving distance of the roasting airflow allowed much more opportunities of heat loss during the process.

This may also be the reason that, although the idea seems pretty solid, there aren’t many roasters (especially roasters that have a capacity larger than 1kg) that currently uses this design. One more popular example is: Roest roasters (200g, electric sample roasters).

To combat the energy efficiency issue, entered “Recirculation burner” drum roasters.

Recirculation burner drum roasters

Now we truly entered the more “modern” era of coffee roasting machine design and manufacturing.

Recirculation burner drum roasters added 2 major tweaks to its predecessor:

- an afterburner (basically a burner that operates at even higher temperatures than a traditional coffee roaster heat source burner, and has the ability to “burn away” the smoke particles inside the roast exhaust air, essentially cleaning up that air to make it smokeless)

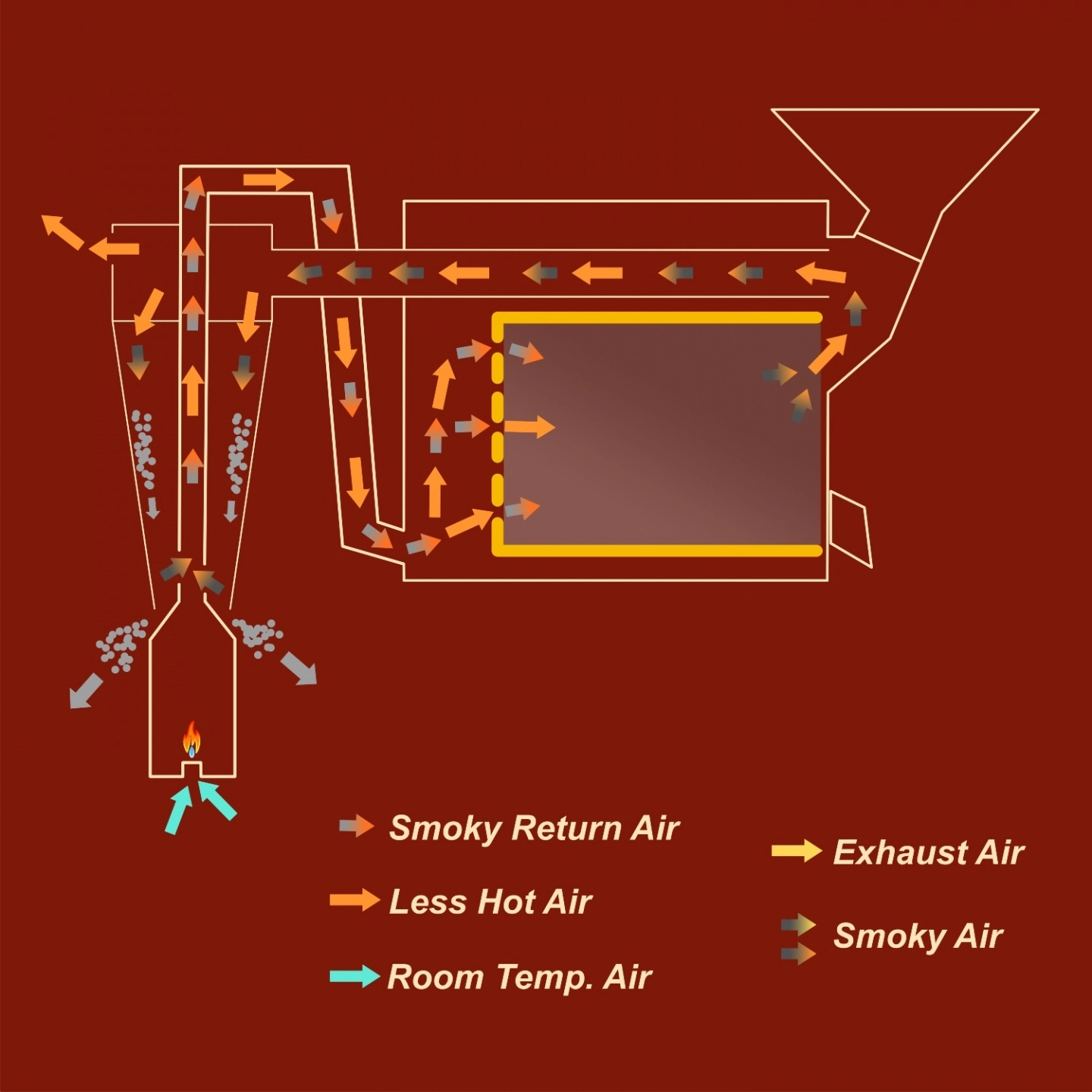

- a recirculation exhaust piping design (as shown in the graph, readers can compare it with the graph of the “separate burner chamber drum roaster”)

The main upside of these recirculation burner roasters are their improved roast energy efficiency. Since the exhaust air leaving the roasting chamber is still of very high temperatures (easily 200°C or more), if the exhaust air can be “cleaned up”, we can just slightly heat it up a bit and reuse it for roasting again.

On a recirculation burner roaster, the cyclone (just like in other types of drum roasters) takes care of the ash, chaff, and debris while the afterburner burns away the smoke and other gaseous by-product of the roasting process, making the exhaust air clean and ready for reuse.

However, as illustrated in the graph below, one issue of this very clever system is that the cleanliness of the recycled air relies on the afterburners ability to burn away the smoke.

If the afterburner’s temperature drops below a certain point, it may no longer be efficient in cleaning up that roasting air, and smoke could start to be recycled into and build up inside the roasting chamber.

And since we usually have to apply less heat at the end of the roast, this could potentially be a bigger issue than one first thought of it. At the end of the roast is also when the beans start to increase in porosity, so if the roasting air is tainted with smoke during this stage, the final roasted product has a high chance of carrying over that smoky trait into the cup.

Luckily, manufacturers of this kind of roaster have invented ways to avoid this problem. Without going too deep into each particular roaster’s design, we can conclude that the main idea behind each solution is pretty similar: to maintain the afterburner’s temperature at all times and try to control the input roasting air temperature without needing to (drastically) adjust the burner’s operating temperature.

Famous examples of these types of recirculation burner drum roasters include: Loring roasters (technically the drum doesn’t rotate on a Loring, but overall the idea is similar), IMF roasters (with a perforated drum also)...etc.

< Other Types of Roasters >

Fluid bed coffee roasters

Also known as “hot air roasters” or “popcorn roasters (when the capacity is small)”, fluid bed coffee roasters function just like a popcorn machine, blowing hot air into the roasting chamber to heat up & mobilize the coffee beans at the same time.

This design gives the roaster a very simple heat transfer characteristic, relying heavily on the hot air to transfer the roasting heat via convection onto the roasting beans and hence has the potential to produce extremely uniform roasted products. Also, it is very straightforward & uncomplicated to control while roasting (just adjust the temperature of the input hot air), making roast control also easy & straightforward.

However, the main disadvantage is that the mobilization (churning & mixing) of the coffee beans & the roast energy supply is tightly tied together. On less refined versions of a fluid bed roaster, users might find themselves wanting to lower heat towards the end of a roast but fearing that the mixing of the beans will become too uneven. However, a handful of modern variations of the classic fluid bed roaster (Typhoon roasters, for example) already solved this issue by introducing an independent mixing/churning system

Another potential problem with the fluid bed roasting system is “ roast energy efficiency”. Since the “throughput” of the hot roasting air is significantly larger compared to traditional drum roasters (due to the fact that the airflow also needs to be sufficient to agitate the beans), fluid bed systems remain one of the more energy-consuming roasting methods. This could be remedied with a hot air recirculation system, but currently most fluid bed roasters don’t bear this design.

Well-known examples of the fluid bed roaster category includes: Ikawa roaster (small electric sample roaster), Fresh Roast SR540 roaster (small electric home roaster), Nucleus Link roaster (small electric sample roaster), Sivetz roasters, Typhoon roasters…etc.

Center-placed Infrared roasters

Some modern roasting machine manufacturers have started to implement “radiation heat transfer” in order to roast the coffee beans more effectively & efficiently.

Since radiation does not need to first heat up the air and then use the heated air to transfer heat onto the roasting beans, manufacturers that uses this kind of technology tends to design the roasting chamber in a way that the radiant heat from the heat source can directly beam onto the coffee beans thus minimizing heat loss.

One of such designs is a “center-placed Infrared” roaster (as shown in the graph below).

![]()

Bearing a look very similar to the traditional drum roaster, the essential difference of a center-placed Infrared roaster is the placement & design of the heat source. While radiant heat emitted from the heat source can directly heat up the beans & the drum’s inner surface, the airflow, which is designed to flow over the whole center-placed infrared heating element, balances out the temperature of the heat source & creates hot air that can give some convective heating.

Also, the drum material selection and inner surface treatment creates a “heat resonator” design, making sure that the radiant heat energy would either:

1. Be absorbed by the coffee & be used for roasting directly

2. Transmit through the bean, and be reflected by the drum inner surface, or

3. Be absorbed to heat up the drum

By "resonating" radiant heat energy within the roast chamber AND drastically decreasing heat energy wasted by unnecessarily hot exhaust air, this kind of roaster design achieved unprecedented energy efficiency and is said to have the potential to use almost 50% less energy per kilogram of coffee roasted.

Examples of the center-placed infrared roasters include: Rubasse roasters (600g, 1.2kg, & 3kg capacities available).

Outro

By now you probably have a rough idea about the main types of coffee roasting machines out there on the market.

However, If you are still wondering about whether you should get a roaster powered by gas or electricity, here is an article that you might be interested in:

Coffee Roaster Buyers Guide 2025 | Pt.2 - Gas or Electric? What You Should Know