With the rising popularity of specialty coffee in global market, many people aim at the market of pour over specialty coffee which also brought up the trend of fresh roasted, fresh ground and fresh brewed coffee. However, speaking of a good cup of coffee, it all starts from the very first step, roasting.

There are so many coffee roasters on the market, and every manufacturer has been constantly making innovation. Then, how should the beginners, the veterans and the owners choose their perfect coffee roasters?

Contents

To choose a perfect coffee roasters for yourself, there are 17 key points that you should take into consideration:

⑩ Differences of infrared radiation

⑬ Exhaust

1. Purchase Price (Range)

There are a variety of coffee roasters on the market. Below is the comparison of the coffee roasters at each price range of 2022.

| Coffee roasters | Type | Cyclone dust collector | Approx. price (USD) | Capacity |

|---|---|---|---|---|

| Home coffee roasters | ||||

| SR540 | Electric fluid bed | no | <1000 | 120g |

| QUEST M3 | Electric direct / half direct fire | no | 1000 up | 250g |

| Bullet R1 | 100% Electric iron drum | no | 2700 up | 1kg |

| IKAWA V3 Pro | Electric half hot air | no | 5000 up | 50g |

| ROEST | Electric half hot air | yes | 5300 up | 120g |

| Rubasse Nano | Electric direct infrared | yes | 4400 up | 500g |

| Commercial manual coffee roasters | ||||

| Yang 801N | Gas half hot air | yes | 6400 up | 1kg |

| Sonofresco | Gas fluid bed | no | 7500 up | 1kg |

| Genio | Gas half hot air | yes | 20k up | 3kg |

| Stronghold S7 pro | Electric tower drum | yes | 15k up | 850g |

| Typhoon | Electric fluid bed | yes | 15k up | 2.5kg |

| Fuji Royal | Electric direct / half direct fire | yes | 18K up | 1kg |

| Probat | Gas half hot air | yes | 17K up | 1kg |

| Giesen | Electric / Gas half hot air | yes | 30k up | 1kg |

| Commercial full-automatic coffee roasters | ||||

| Rubasse Micro | Electric direct infrared | yes | 9.5k up | 1-3kg |

| Diedrich | Gas half hot air | yes | 37K up (with Zenith) |

1kg |

| Loring | Gas hot air | yes | 67k up | 7kg |

The price of each brand of roaster is collected in Taiwan 2022 and may vary from country to country.

2. Roast Capacity

On the market, coffee roasters can be generally categorised into home use and commercial use, and we can take the maximum roast capacity as a simple indicator.

Home coffee roasters: below 1kg capacity

For the beginners and veterans, most of the roasts are below 1kg. The home coffee roasters allow the veterans to try different roasting methods with an affordable price. The beginners may choose this type of coffee roasters as their stepping stone used for delving into more roasting techniques and for fulfilling home roasting and brewing purpose.

Commercial coffee roasters: more than 1 kg capacity with the cyclone dust collector

For coffee bean retailers or coffee shops roasting specialty coffee on their own, it is recommended to use the coffee roasters with more than 1 kg capacity and equipped with cyclone dust collector to meet their needs. A 1 kg capacity roster is capable of roasting 4 batches per hour. If it works 8 hours per day, there are approximately 30 kg roasted beans can be produced per day.

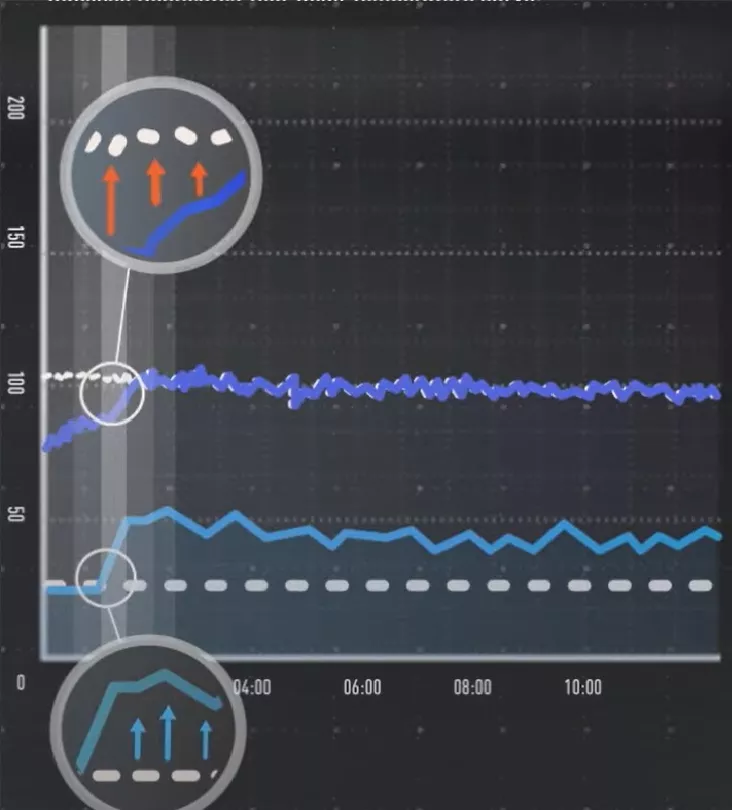

3. Profile Recording

What coffee roasters pursue is the consistency of quality, i.e., the replication of roasting. Keeping track of all the alterations and adjustments during the roasting process is the key to make the replication possible.

Record the roast profiles manually

The roasting result of a type of beans is determined by the coffee roasters himself/ herself to take notes for every detail during roasting, such as temperature and weight while loading and the turning point, the drum temperature of each minute, dehydration point, first and second crack, unloading time, dehydration rate, temperature rising rate, etc. With these details, we can draw the roast profile based on the correlation between temperature and time.

Artisan

Manual recording takes lots of efforts and time on observation and measurement. In order to let the coffee roasters dedicate to the roasting process, the software, Artisan, was thus launched.

Artisan is an open-source software that helps coffee roasters to create multifunctional roast profiles via computer as well as the sensing and recording system. This software is able to record all the information the coffee roasters needs to analyse and monitor the roast profiles. It is also a multilingual system which owns the highest usage rate in the field. Currently, Artisan is widely applied and supported by several coffee roasters.

Original Profile Recording System

The commercial used coffee roasters on the market are usually equipped with a default record system, such as:

- Probat: high-end fully automatic coffee roasters (approx. TWD 1.5 million) equipped with THE PILOT coffee roasters control system is able to manage and monitor all the actions of the coffee roasters.

- Loring: With the application of the programme, Autopilot, to record the profiles.

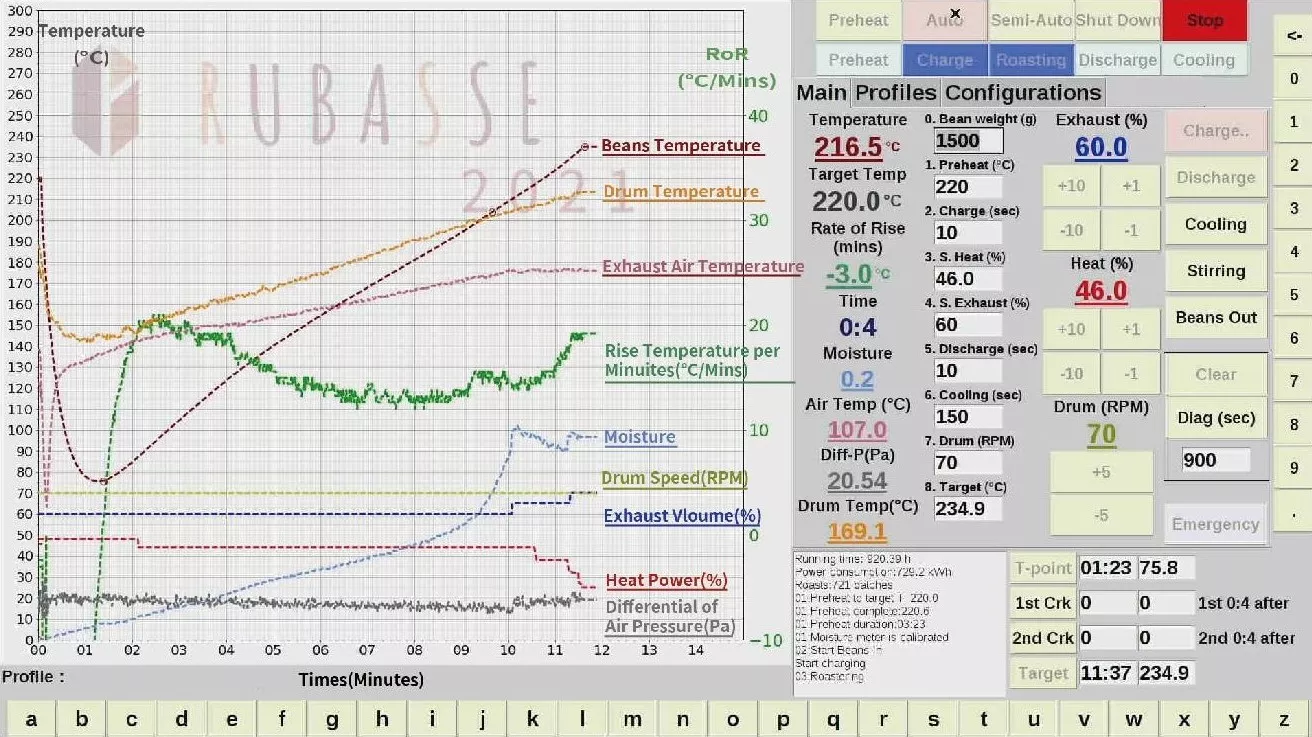

- Diedrich: With the application of Zenith Automation system which costs about TWD 400,000 and it needs to be purchased upon installation

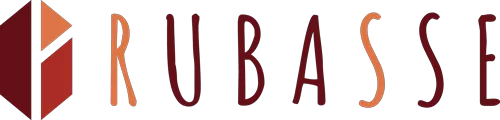

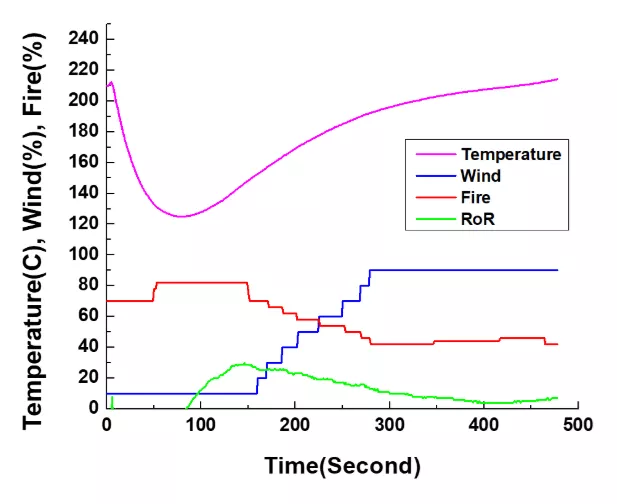

- Rubasse: With the application of self-developing record software which integrates all the operation on the touch panel. In addition to the record of the temperature fluctuations, it can also record the heat, wind speed, wind temperature and rotation speed of the drum, differential pressure, humidity, etc.

4. Method of Operation

Traditional physical operation button controllers

Photo taken from *Diedrich IR-1Traditional coffee roasters usually have physical operation switches and buttons on the machine, so the damper switch, gas valve, electronic thermometer, handles of load/ unload, etc can be seen. This kind of design is relatively simple that each motor has its corresponding controller. Generally speaking, it’s not easy to be damaged and more convenient to be repaired.

Digital Control Panel

These days, manufacturers tend to integrate the conventional switches to the control panel. The advantages of this kind of coffee roasters are: (1) to save space, (2) reduce the size of the machine, and (3) record all the operation process by computer, which provides parameters to be analysed for future adjustment reference.

*Rubasse Infrared Digital Coffee roasters

Photo taken from *Loring S7 Nighthawk

Photo taken from *Diedrich designed for both IR series and CR series

Mobile app connection

Nowadays, smartphones have a wide range of uses, and mobile application for coffee roasters are now available as well. With the app, you are able to control all the operation of the coffee roasters. Panel and buttons are removed from the machine of this type of design; by doing so, the manufacturing cost could be greatly reduced. The novel design is not only eye-catching but also a big selling point.

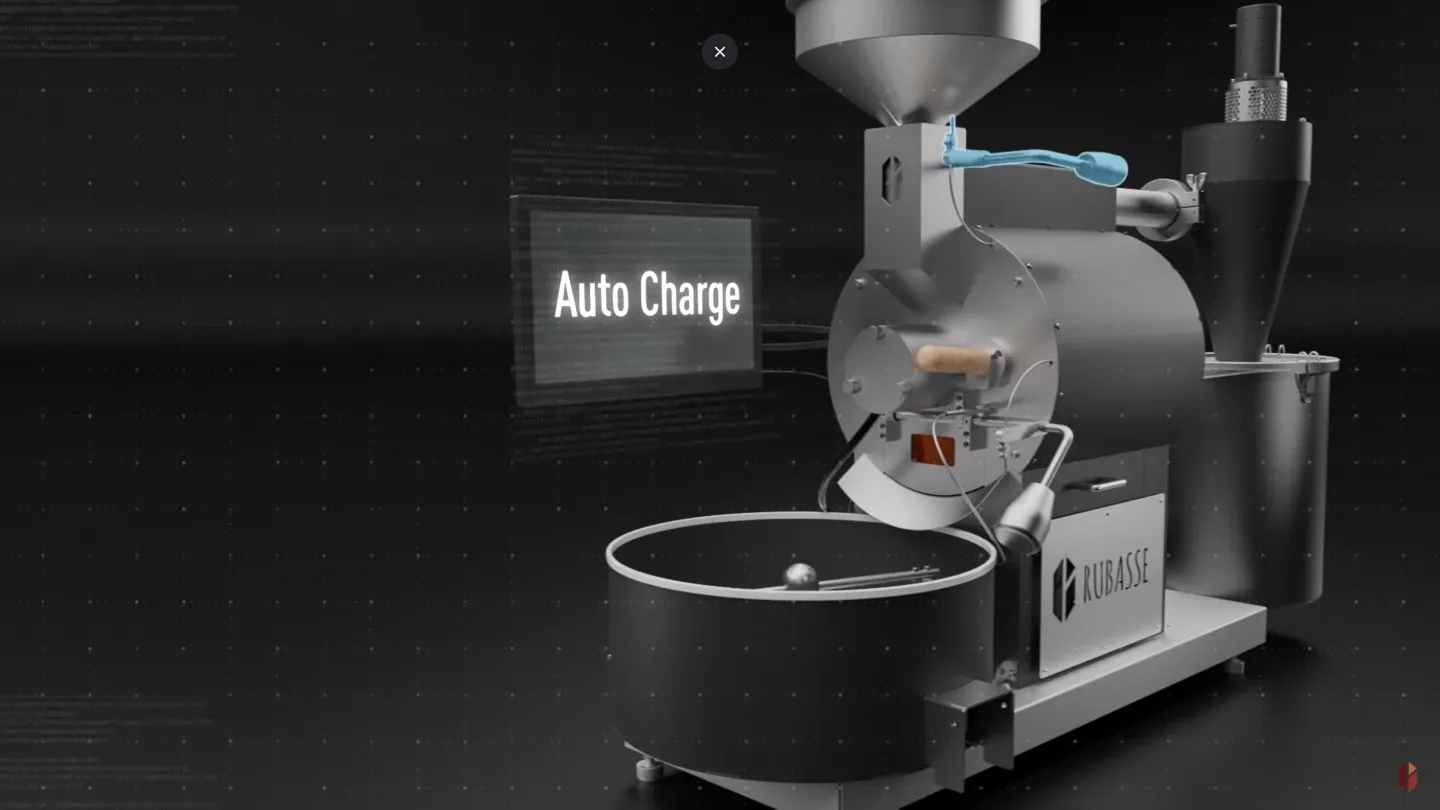

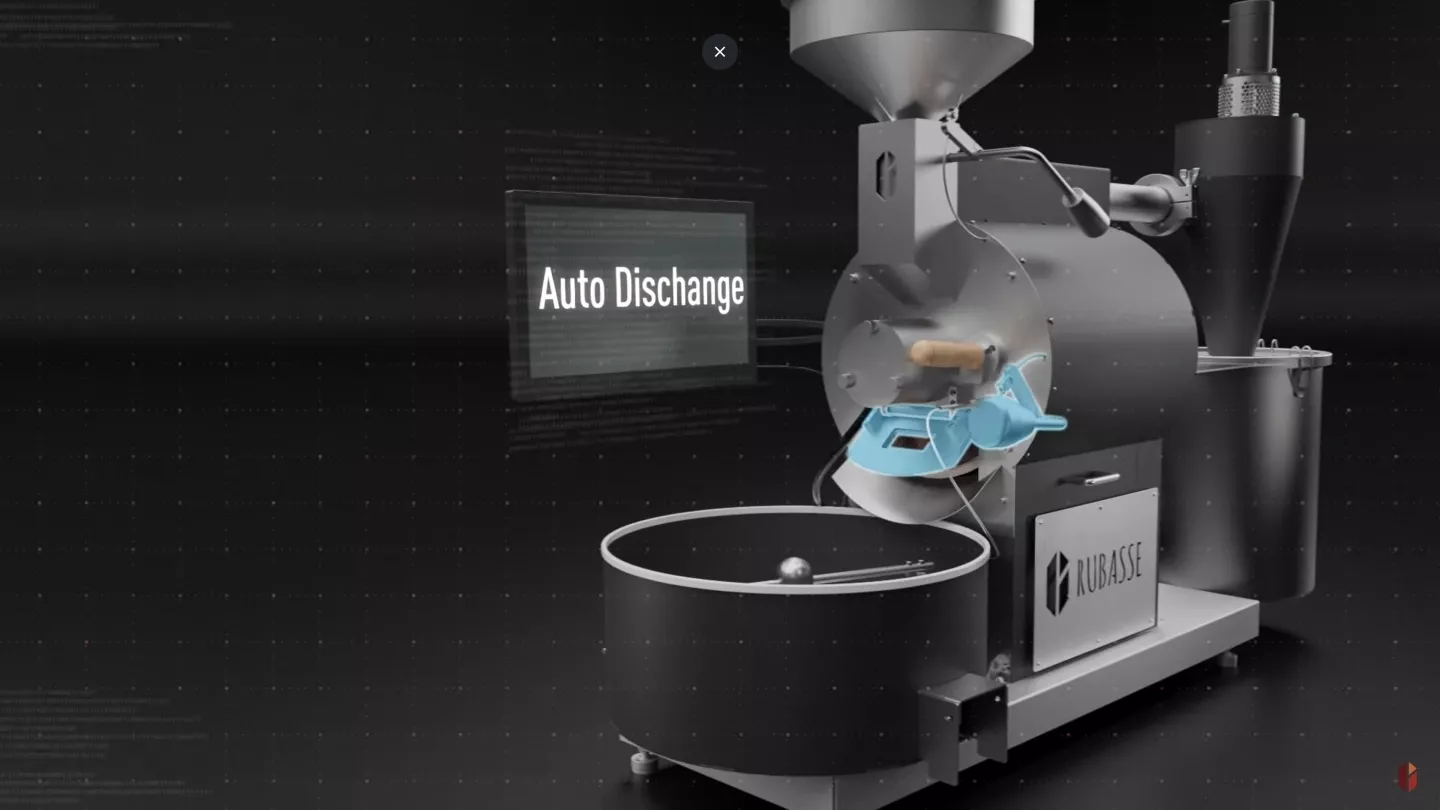

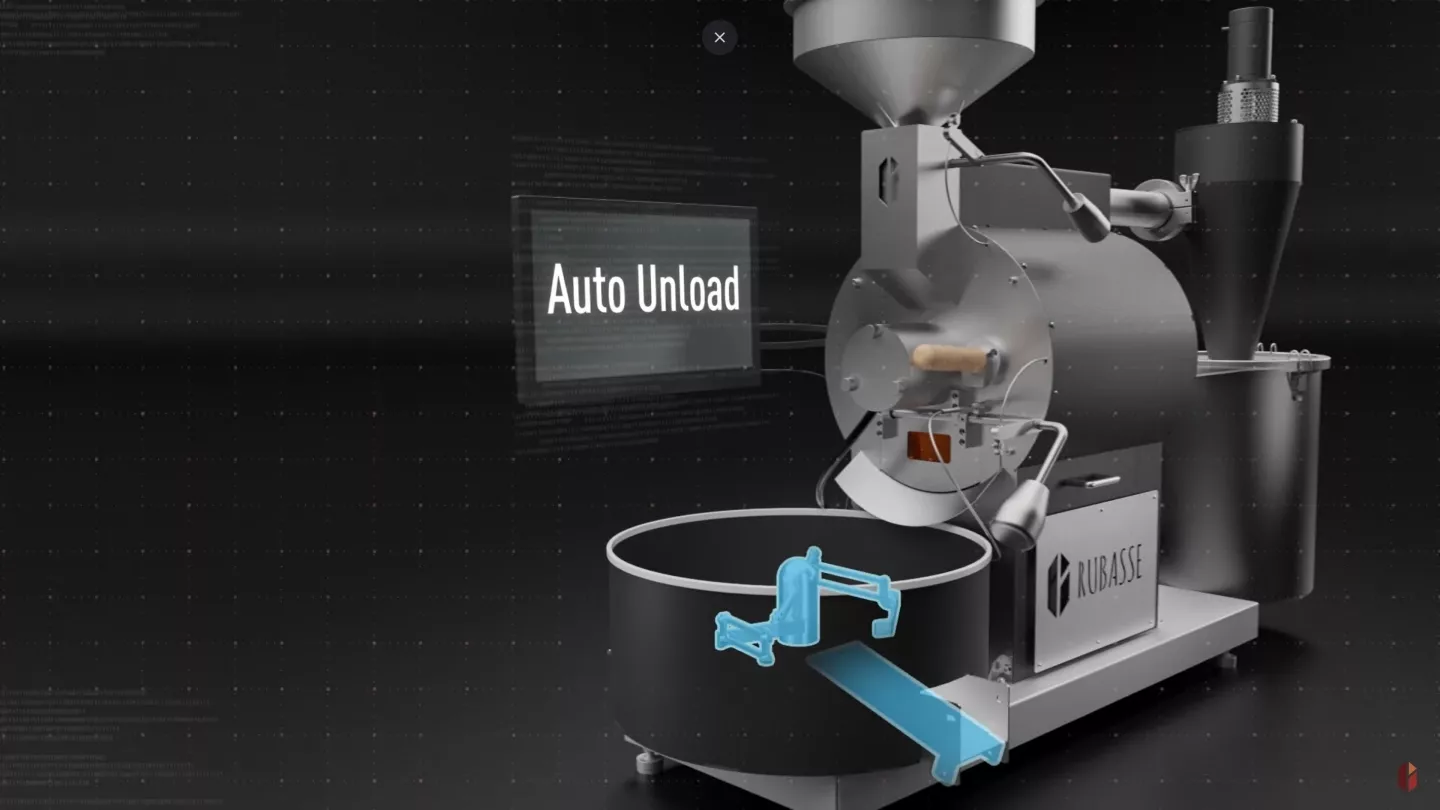

5. Programme Automation (Charge, discharge & Unload)

Charge: To pour green beans from the hopper to the drum.

Discharge: To discharge the roasted batch from the drum to the cooling tray.

Unload: To release the roasted batch from the cooling tray to the container.

Loading, discharge and unloading are the simplest steps in the roasting process and also the steps that do not require professional manpower. If it is full automation, an operator standing by the side of the coffee roasters is then unnecessary.

- Loring coffee roasters are all equipped with automatic loading and discharge valves

- The programme of Probat rasters, the PILOT coffee roasters control system, controls over automatic loading and discharge.

- The programme of Diedrich coffee roasters, Zenith Automation, control the valve of discharge gate through the control panel.

6. Flavour Reproduction

Following the set-up profile through the computer, the coffee roasters (person) does not need to conduct any operation during the roasting process. The functionality of replicating the profile enables the veterans and the owners to save lots of efforts on maintaining the consistency of the taste and flavour.

Auto coffee roasters

There is one type of auto coffee roasters on the market which functions to automatically reach three different roast degree, light, medium and high roast. After starting the coffee roasters, it will continue heating. The roast degree is only determined by bean temperature which will lead to unchangeability of the recipes. It is unable to make changes according to the size of the batches and other requirements of dynamic flavours. In addition, it does not have the air and heat compensation mechanism, so it is hard to keep consistency. This type of roast method does not function based on the recorded profile.

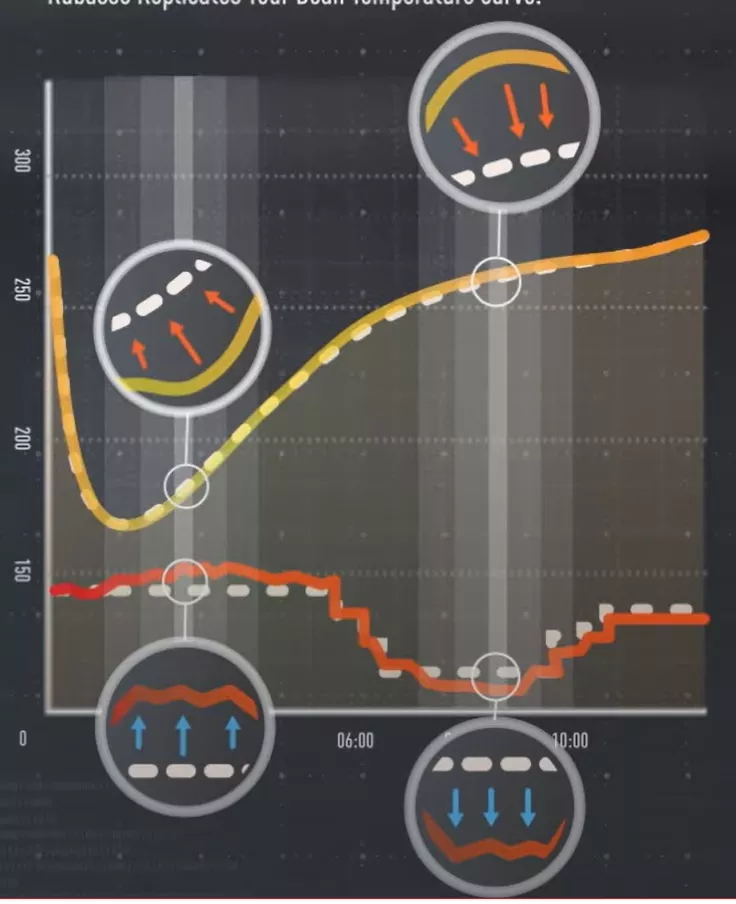

Computer-calculated compensation based on the recorded profile

The professional automatic coffee roasters is able to make compensation according to the record and further compensate the imperfect environment condition.

The 2 key points of professional real-time compensation:

- The reaction time of heat control: When there are environment variables, the heat control must rely on rapid reaction/ response time. Otherwise, even if the computer detects the temperature difference and increases the heat, it usually takes a long time to compensate for the difference. Therefore, an automated system though it has, it is unlikely to make real-time compensation.

- Parameters of bean & air temperature, airflow & heat power, the rotation speed of the drum, etc. are recorded and real-time computer-calculated compensation will be made accordingly. For example, if the profile was recorded in summer, the computer will adjust the heat to meet the required temperature in winter to make the current profile and the recorded profile consistent.

The automated coffee roasters on the market:

- Probat high end fully automatic coffee roasters: equipped with gas hot-air and computer-calculated compensation system able to record the roast profile and replicate the roast results.

- Diedrich: ses Zenith Automation computer system able to record all the actions and duplicate the roast profile. However, it is equipped with semi-hot air and diecast drum which lengthen the reaction time. The reaction time could be as long as one minute. Thus, to reproduce the algorithm is quite challenging.

- Loring: with the application of Autopilot computer system and gas hot air heat recycle system to duplicate the profile and to stably reproduce the flavour.

- Rubasse: utilises the infrared radiation directly irritating the beans with extremely short reaction time and instant compensation for the surrounding condition. With Rubasse PID Backtracking Algorithm, the coffee roasters is able to automatically make compensation for the imperfect environment condition affected by the weather and enables the roast no longer be influenced by the surrounding temperature, humidity and other factors to genuinely replicate the taste and flavour.

7. Thickness of the Drum

The material and the thickness of the drum will directly affect the thermal conductivity to the green beans and further affect the roast method.

The thick drum material - cast iron

Thick drum usually is made of cast iron since the material contains graphite which has better thermal conductivity. Besides, to make a cast iron drum is not cheaper than a stainless steel one.

The thin drum material- stainless steel

The thin drum is usually made of stainless steel which contains nickel and some precious metal. The thermal conductivity is only one-third of cast iron.

The correlation of thermal conductivity and heat recuperation

Many people might mix up thermal conductivity and heat recuperation and consider cast iron has better heat recuperation due to better thermal conductivity; stainless steel has worse heat recuperation because of worse thermal conductivity.

Under the same volume condition, the specific heat capacity of stainless steel is about 1.5 times of cast iron. The larger the specific heat capacity is; the weaker the heat absorption or heat dissipation of the object is. Therefore, the heat recuperation effect of stainless steel is actually better in the same volume.

The difference between thick and thin drum

Why the traditional direct fire and half direct fire do not use thin drum?

Using gas heat source to heat the drum directly will make the drum overheated, and the beans may easily be scorched and have a bad taste. As a result, increasing the drum thickness can avoid the drum being overheated.

The thickness of the traditional drum lining is usually 5-10 mm. The thicker the lining is, the better the heat recuperation is, which means it takes a longer time to preheat and react. After turning off the heat, the temperature will continue rising due to heat recuperation. Accordingly, the reason why using the thick drum is due to the limitation of traditional heating.

The volume of the thick drum is also bigger than the thin drum, and the heat recuperation is thus more. If the drum temperature cannot be appropriately controlled. As it reaches the target temperature, the drum temperature will keep rising. The actual bean temperature will be higher than expected. To avoid the kind of situation, the heat needs to be turned off to conduct the sliding operation. The sliding operation is the operation method that minimises the temperature fluctuations and maintains the temperature within the specified range and heats up slowly.

The thin drum has less heat capacity due to the volume which means it is very sensitive to the temperature change. The operation is very flexible and is possible to stop anytime. The temperature can be precisely controlled to attain the effect of sliding.

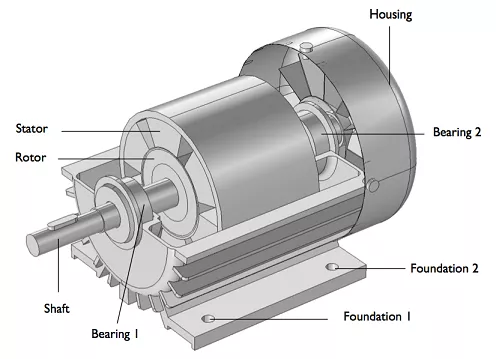

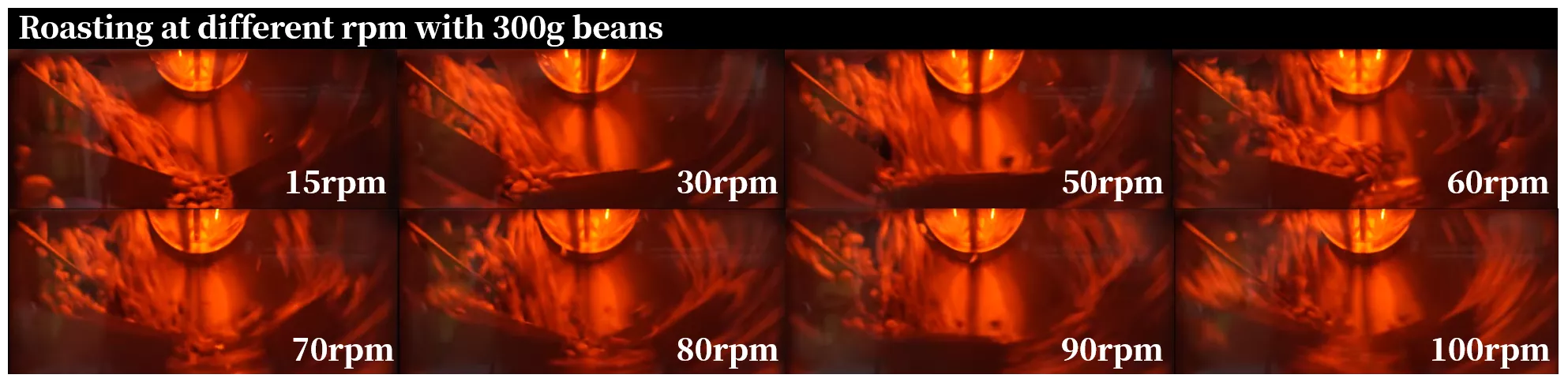

8. Drum Rotation

The rotation speed of the drum will influence the uniformity of the heat absorption of the beans, the heat transfer between the air and the beans, the contact between the heat source and the beans, and further affect the time taken for dehydration and other chemical reaction.

The basic model (with fixed rotation speed)

The rotation speed is unchangeable. You can only switch on or off and drum motor.

The advanced model (with flexible rotation speed)

The rotation speed of the drum can be adjusted by adding the frequency converter to the motor. However, there will be a low limit of the rotation speed.

High-end model (with flexible rotation speed and changeable rotation direction)

The drum equipped with precision motor technology allows the precise adjustment of the rotation speed. Furthermore, the rotation direction is also changeable on some models.

There is a close correlation between the rotation speed of the drum and the high limit of the applied heat. If the rotation is too slow, the beans may not be stirred and aired properly which results in the unevenness of the roast. If it rotates too fast, the beans may spill when tossing about. Additionally, the effect of exhaust and airflow will further cause the beans lack of steaming which greatly influences the layers of flavour and the bean structure, i.e., it relates to the exaction. On that account, it is very important to adjust the drum rotation accurately according to the different roast requirements.

9. Heat Source: Heating Technology

Heat source of the coffee roasters on the market

Direct fire coffee roasters

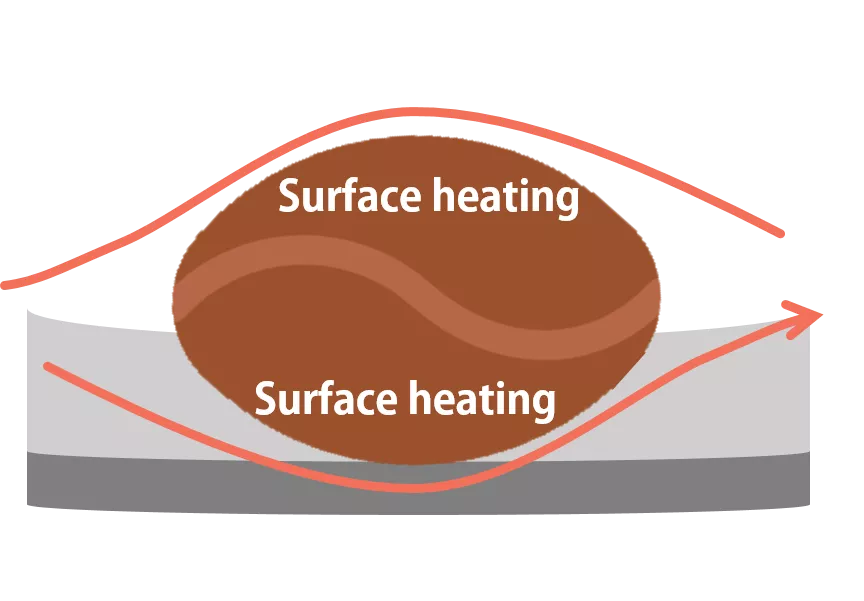

The heat source includes gas fire and charcoal fire. The fire can directly contact the beans through the holes on the top and the bottom of the drum and the heat source is absorbed from the outside toward the inside of the beans. The improper operation may make the surface of the beans overcooked before the core is cooked which results in uneven roasting. The kind of drum with holes makes the heat more difficult to control and leads to longer roasting time and more severe caramelisation reaction.

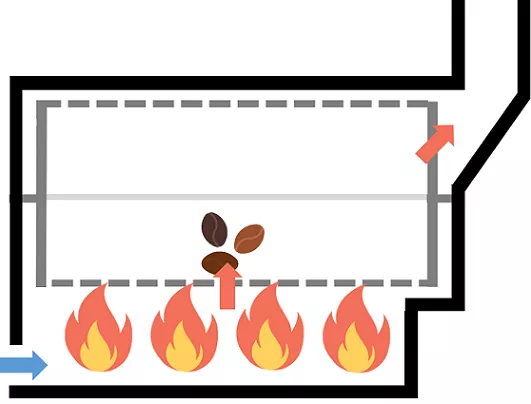

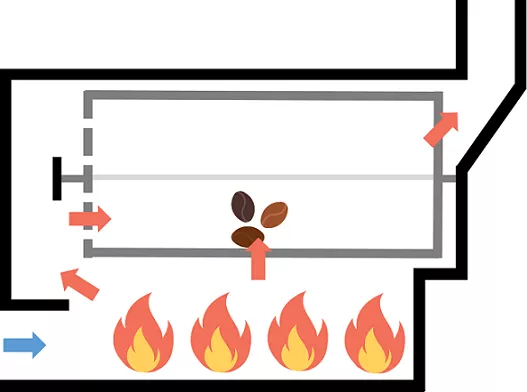

Half hot air coffee roasters

The half hot air coffee roasters relies on the heat conduction and heat convection, and the heating ratio may vary with different model designs.

Unlike the direct fire one, there is no hole on the top and the bottom of the drum. The holes are designed at the rear of the drum and the heat source will not directly contact the beans. Although the heat brought by the hot air can heat up the beans evenly, the effect of the heat conduction of the drum still should be taken into account. Thus, we need to be very careful about temperature control.

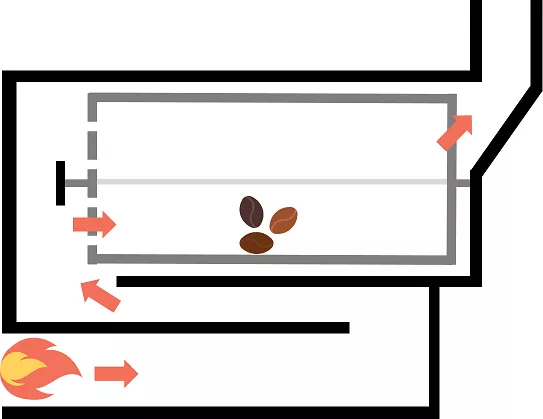

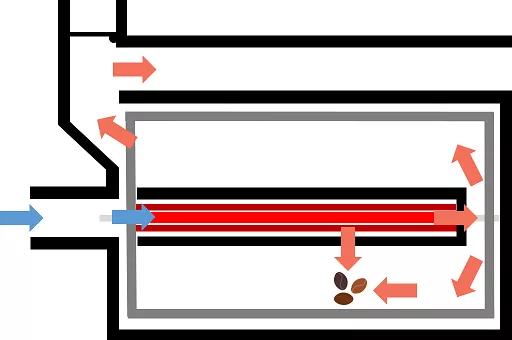

Hot air coffee roasters

The hot air coffee roasters has another roasting chamber that introduces the hot air to the drum. By doing so, the beans can be roasted relatively more uniformly and the temperature control is also easier. It can reach the required temperature without heat recuperation issue so the roasting will be much simpler and stabler.

It should be noted that after the beans are heated by the hot air, the hot air will be discharged from the coffee roasters. The heat consumption here is bigger than the direct fire and half hot air coffee roasters.

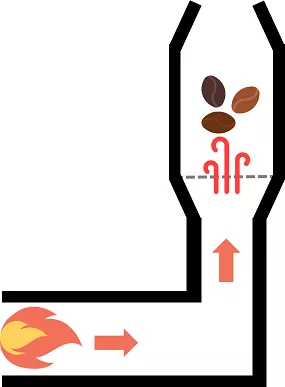

Fluid bed coffee roasters

The fluid bed coffee roasters is like a popcorn popper which sends heated air from below the beans to the top and the hot air as well as the air pressure can heat up and toss about the beans at the same time to achieve the purpose of even roasting.

The advantage is that the coffee roasters structure is simple. The roasting chamber is made of transparent glass, so the progress of colour changes and chemical reactions of the beans can be easily observed. The temperature control of hot air is not complicated and preheating is unnecessary. The disadvantage is that the roasting chamber is small. The hot air continuously flows in and out, and the hot air cannot be recycled and the heat consumption is the biggest compared to the others.

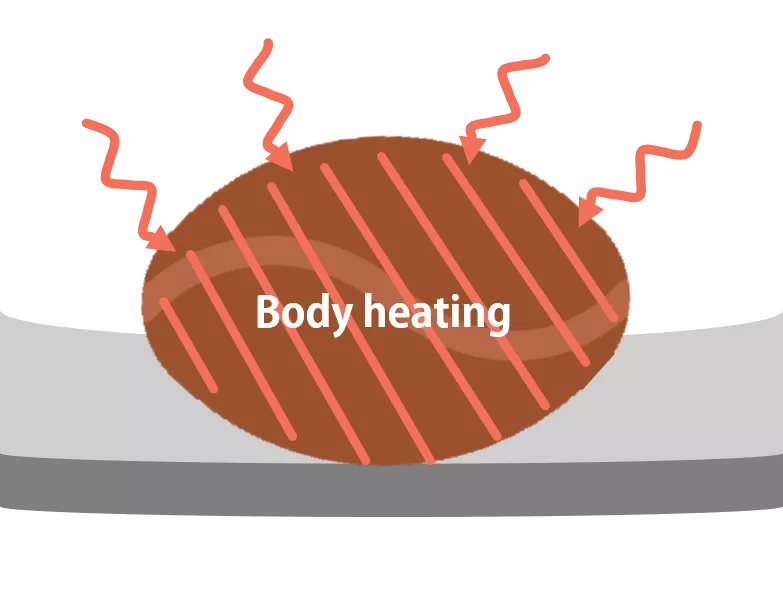

Infrared coffee roasters

The infrared direct irradiation heating technology utilises the wavelength suitable for heating coffee beans (grains) through irradiation transmission. The transmitting distance of the radiation going through to the coffee beans can be up to 1 cm. The advantage is that the surface and the core of beans can be heated uniformly. Higher roasting efficiency and uniformity of heating can be achieved. Due to the fact that the infrared radiation irradiates the beans directly in the drum instead of from the outside of the drum, the heat source can be particularly aimed at the beans. Compared with the conventional half hot air coffee roasters, the reaction time of the infrared coffee roasters is approximately 20 times faster. No open fire is used throughout the whole process so there will not be any smells coming from charcoal or gas, and there is no silverskin burnt by the open fire. As a consequence, smoke emissions will be even less.

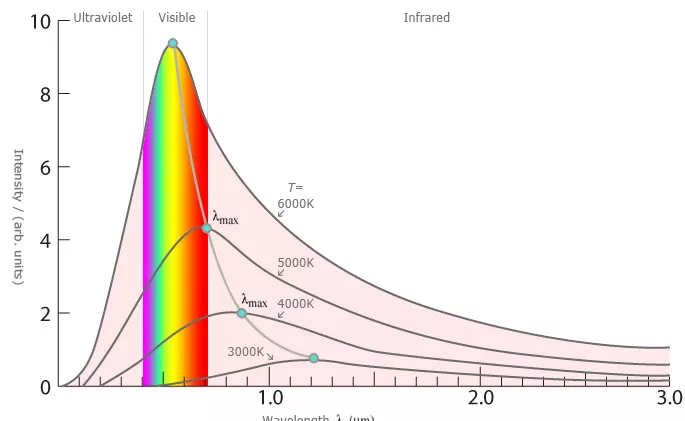

10. The Difference between Infrared Radiation and Far Infrared Radiation

Because of the features of black-body radiation, as long as the temperature of an object is higher than absolute zero, infrared radiation will be generated. When the temperature rises, the intensity of the emitted infrared radiation will also increase at the rate proportional to about the fourth power of the absolute temperature. Generally, wavelengths are classified into near-infrared radiation, mid-infrared radiation, and far-infrared radiation. With different wavelengths, the emitted energy density is also different.

When heating, the temperature of Short-wave infrared lamp is as high as 2200 ℃. Therefore, nearly 100% of applications are short-wave near-infrared radiation with high transmittance. The transmitting distance of the radiation going through the coffee bean can be up to 1 cm. On the market, it is mostly applied to medical equipment.

The far-infrared coffee roasters utilises half hot air blower with ceramic gas heater plates. The temperature of the ceramic plates is at about 310 to 755 ℃, and it emits long-wave far-infrared radiation. The energy density of far-infrared radiation is much lower than that of high-temperature infrared lamps. In addition, the transmittance of far-infrared radiation to grains is very low, 1um only. It is not possible to transmit through the iron drum if the heating system is set outside of the drum.

Therefore, it still mainly relies on the heat conduction and heat convection of the drum, and the heating efficiency is not good.

11. Roasting Techniques

Steam roasting & steam simmering

For drum coffee roasters, there is a certain proportion of steam flow existing in the drum during the heating process. It acts on the green beans in the form of steam. Before the first crack, the stage is called “steam roasting” and “steam simmering”. The purpose of steam simmering is to take use of the steam convection to achieve the steaming effect similar to the electric pot.

The fluid bed type coffee roasters utilise hot air and air pressure to heat and stir the beans as well as take out the water through the air flow during heating. The water will be completely discharged from the roasting chamber and the hot air will be the only heat source. Therefore, the steaming roasting method is not applicable to the fluid bed coffee roasters.

Layers of coffee

Some people like the simple tasting and some like the complex tasting of coffee. The so-called “layers” is the different roasting levels of the roasted beans which can be observed through the cross-section of the bean. The different roasting levels result in a mixed flavour of the darker roasted surface and the lighter roasted core of the bean.

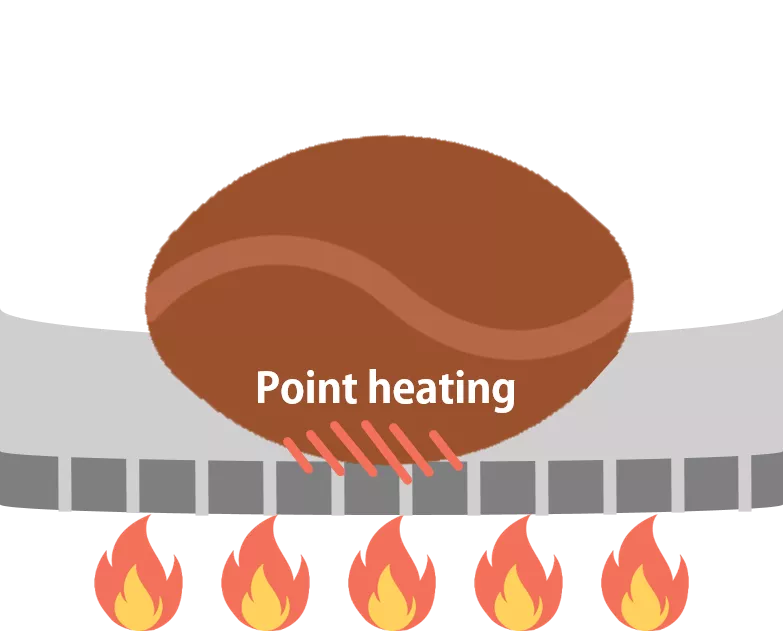

Direct fire coffee roasters

The smell and aromas of coffee will be produced easily because the heat source directly contacts the beans. The heating aims at a certain spot of the bean so the uneven roasting takes place easily. The layers would be the most obvious. To roast the coffee with balanced taste requires lots of experience.

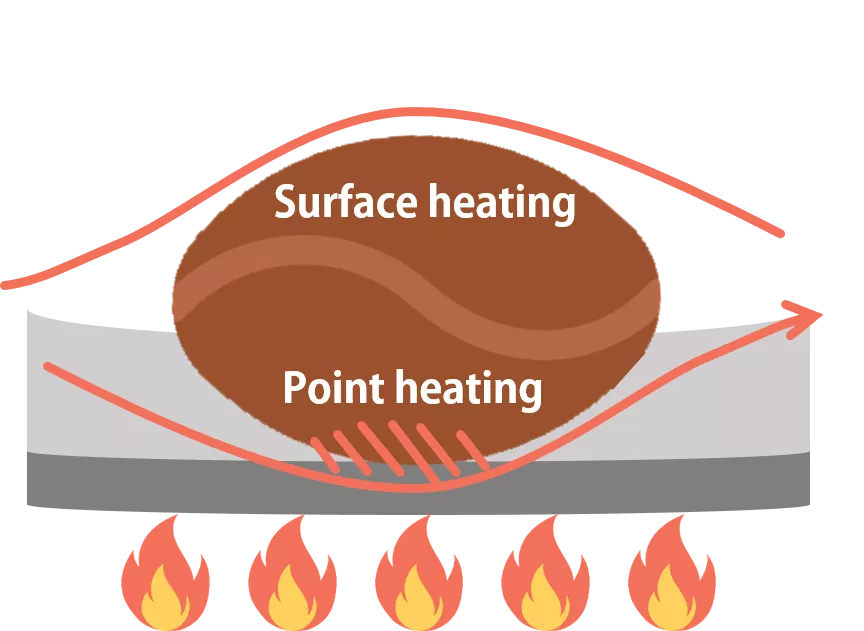

Half hot air coffee roasters

Half hot air coffee roasters' heating system relies on the heat contact from below the beans and the drum as well as the comprehensive heating by the hot air. In this way, the hot air can make up the uneven heating issue of direct fire type coffee roasters and make the taste simpler, brighter and more uniform.

Hot air coffee roasters

Hot air roasting utilises the hot air to heat the surface of the beans thoroughly which enables the heat to be transmitted to the core of the bean more easily and makes heating more evenly. On that account, it is hard to find incompletely roasted beans here. The original and simple taste of coffee could be presented by this type of coffee roasters.

Infrared direct heating coffee roasters

The short-wave infrared light directly irradiates to the beans with lamps. The short-wave infrared radiation has good transmittance (up to 1 cm), which can uniformly heat the core and surface. It is the most uniform heating method. After the long-term testing by the users, it was found that since the infrared lamps are placed in the middle of the drum, the high-temperature area surrounding the lamps with the regulations of drum rotation speed can be used to create different layers of the core and surface of the bean.

12. Comfort of Environment, Energy & Waste Heat

Comfort of environment

Waste heat refers to the extra heat energy produced by heaters and machines that can not be reused.

During the traditional roasting process, enormous waste heat would be produced and spread, which makes the roasting environment become very hot. This explains there is a large proportion of heat source being wasted. Taking the gas coffee roasters as an example, 80 percent of heat energy will turn to waste heat. It is mainly because the gas heat source is located outside of the drum, only part of the heat source is applied to the drum. The waste heat makes the area around the coffee roasters become very hot and further spread to the roasting environment. As a consequence, low thermal efficiency makes the energy wasted and produces extra heat which results in an unfriendly roasting environment.

The energy efficiency of infrared direct irritation heating technology

The infrared light lamps installed in the middle of the drum irritates the beans directly and the cold air is exhausted from the inlet cone through the glass tube to be heated by the infrared radiation lamp and afterwards, introduced to the drum. It can not only dissipate the heat to extend the lamp’s life but generate more hot air to heat up the beans. In addition, when the infrared radiation irritates the drum, the drum is not only heated directly but also continue reflecting the radiation. The inside of the drum becomes a very nice reflector that reflects the radiation and heats the beans again and again. After practical testing, the discharged wind temperature is just around 100 ℃. The heat source is only used to heat the beans not used to heat up the extra air so the energy efficiency is extraordinary. During the roasting process, the temperature of the machine itself is only 40 ℃ and the waste heat is minimised so that the surroundings can be kept cool. Even in the air-conditioned room, the capacity of the air conditioner will not be affected, either. Accordingly, a large amount of energy can be saved.

13. Exhaust, dehydration, humidity, Maillard Reaction and Silverskin collection

With fixed heat, if we increase the airflow, the air temperature will decrease; vice versa, if we decrease the airflow, the air temperature will go up. During the dehydration process, steam needs to be exhausted properly to reduce the humidity of the drum and further to avoid steaming effect like the rice cooker which will facilitate the decomposition of the tannic acid in the beans and produce a bad taste. In order to eliminate the uneven dryness of green beans issue, we can reduce the airflow and use the steam simmering method to extend the dehydration time to ensure the even dehydration. During Maillard Reaction, we can adjust the airflow and wind temperature to process the changes caused by chlorogenic acid. After the first crack, to avoid the influence of burnt silverskin on the taste, we can increase the airflow volume so that the silverskin can be smoothly pumped away from the drum.

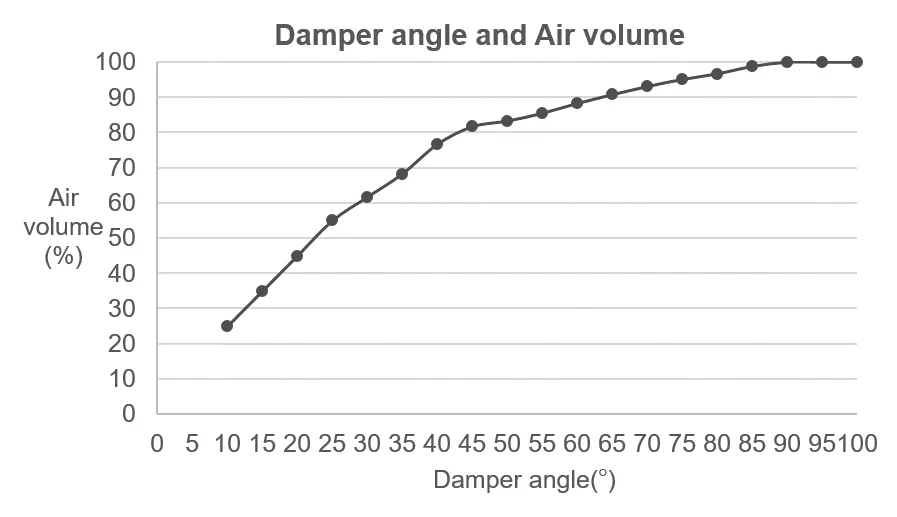

Several examples indicate the important correlation between exhaust control and roasting results since it causes different chemical reactions. Therefore, precise control of the exhaust is the key to a good roast, taking the lead on the diversity of coffee taste. The airflow volume control can be generally categorised to physical damper butterfly valve, induction motor and DC inverter motor. What are the different features of the applications?

Basic - Physical damper butterfly valve

Some of the traditional coffee roasters are without the airflow volume control which is only equipped with a switch for turning on and off. This kind of design makes it difficult to have the roast with a good taste so there is usually at least one valve, the disk, to control the airflow volume by adjusting the angle of it. The trivial angle changes will greatly affect the air volume. However, because the adjustment is not linear with the resulting air volume, it is difficult to control it precisely. Some slight angle changes of the disk may result in a drastic impact of the air volume.

Advanced - Traditional motor with frequency converter

The traditional motor is an induction motor designed to induce current. The speed of the current itself might be fluctuating. Just like the common electric fan, when you try to block the fan, it will decelerate due to the added loading. If adding the frequency converter to the induction motor, the theoretical rotation speed and the actual speed still varies which makes it difficult adjusting the air volume precisely. On the practical roasting, it makes the coffee roasters unable to duplicate the operation.

Advanced - Brushless DC Motor

The high-end coffee roasters are usually equipped with a DC frequency converter triggered by the DC brushless motor. It is small in size and strong in power. It is capable of controlling the airflow by fixing the rotation speed and accurately attaining the required airflow volume. If you try to stop the DC motor fan, the loading will become bigger, the motor itself will increase the current and restore the original speed setting. As a result, the cutting reaction will continue to occur and no deceleration will happen even if it is blocked by other objects. It is very stable and practical in use.

14. Silverskin Collection

During the roasting process, there are quite a lot of dust, crumbs and silverskin (chaff) coming out from the green beans. In order to avoid them discharging along with exhaust and making a mess, the post-treatment of silverskin before discharging is also a very important step of roasting.

Home use - strainer and filter cotton

The general household coffee roasters do not particularly have a dust collector with the exhaust system. Usually, the air is discharged to the rear of the machine, or the small space behind the machine with a strainer or filter cotton to collect the silverskin. The former will directly affect the environment; The latter will affect the air volume due to the chaff blockage of filter which leads to the decline of airflow volume and the inefficiency of dehydration. The filter needs to be cleaned whenever finishing the roast. Thus, for the coffee roasters used for commercial purpose, it is not going to be the first option.

Commercial use - cyclone dust collector

When the dust and silverskin are brought into the cyclone dust collector with the airflow, the dust collector rotates at high speed in the cone-shaped cylinder where the centrifugal force is much bigger than gravity which separates the solid and the gas. Then the physically heavier silverskin rotates down to the collecting bucket; the lighter smoke and gas are discharged from the top of the cylinder to the static machine to remove smoke.

If without the cyclone dust collector, the silverskin and smoke will be discharged into the static machine directly and a large amount of silverskin will block the collecting plate which weakens the effectiveness of the static machine. Furthermore, it will affect the discharge and roasting process. Therefore, for commercial purpose, it will be best to have a cyclone dust collection device facilitating the roasting efficiency and minimising the silverskin issue.

15. Smoke Removal System

When the roasting temperature goes over 160℃, it will start generating smoke. Apart from the silverskin, if the smoke and dust are not treated properly, they will be emitted and cause pollution to the environment.

Static machine

Most shops utilise the static machine to remove smoke and to degrease at the rear of the coffee roasters. The static dust collecting chamber apply the principle of charge interaction that a positively charged object will attract a negatively charged object to make the dirty and greasy particles charged and attached to the dust collecting plate. Then, the air will be purified and discharged. The advantage of using a static machine is that it is an energy-saving and low-cost installation. The treated air still has a smell of roasting. The standard solution is to use the activated carbon filter at the end of the exhaust to lessen the smell. The activated carbon filter needs regular maintenance and replacement.

Afterburner

Recently, some people will use afterburner to burn the gas produced by roasting at the temperature of 500 ℃ or higher to eliminate the chemical substances existing in the gas.

The afterburner must heat up the chemical molecules in the air to at least 500℃ to reach high efficiency of combustion decomposition. Therefore, using an afterburner is highly energy and fuel consuming.

According to the review of users, the energy it takes for conducting the post-combustion treatment is 5 times more than roasting.

In addition, an afterburner is expensive, even twice the price of the coffee roasters itself.

16. Energy Consumption

Traditional

For the coffee roasters that take gas as the energy source, the cost of the gas for roasting a batch is generally around USD$0.03-0.1 which is not much.

The electricity cost on roasting one batch by the electric heating coffee roasters is about USD$ 0.2 for around 3-5 kWh.

Infrared electric heating

For energy consumption, a roast of a batch done by Rubasse fully automatic infrared coffee roasters takes approximately 0.6 kWh of electricity which costs less than USD$0.06. In the long run, it can save a lot of expense on energy consumption for the users.

17. Productivity & Manpower Cost

The coffee roasters (person) plays a crucial role in the roasting process. Generally speaking, the salary for a coffee roasters is about USD$1,700-2,300 per month. The experienced coffee roasters usually choose to start their own business. If the owner him-/herself is a coffee roasters, he or she still needs to stay by the side of the machine while roasting. For an owner, the invested time is very uneconomic.

The benefits of full automated

The full automated equipment allows the coffee roasters to conduct the repetitive roasting work by itself. The users just need to charge the green beans and the rest roasting process can be done by the machine. It helps the owners to save a great deal of time and expense on the professional coffee roasters.

If the preferred profile is found, the owner even can hire a part-time worker to pour and select the beans. The most complicated process is roasting; however, it can rely on the coffee roasters to replicate the profile of roasting. One person is sufficient for taking care of 3-6 coffee roasters which help to minimise the cost on labours.

Last but not least, when choosing the full automated coffee roasters, the most important is whether the coffee roasters is capable of replicating the flavour and taste. If it just simply has the beans roasted like the simple auto coffee roasters, it is impossible to meet the customers’ requirement nowadays.

Conclusion

After viewing the pros and cons of a variety of functions and designs, if you have a better understanding of the coffee roasters? Before purchasing your coffee roasters, please do make a comprehensive comparison of the coffee roasters to get the utmost out of performance and functionality.

Rubasse is dedicated to researching, developing and integrating the most intelligent coffee roasters with the features of high flexibility and productivity. Taking the above 17 points into consideration, we try our best to put the ideal into practice:

- Price and roast capacity: Coffee roasters designed and made in Taiwan meet the veterans and owners requirements such as functionalities, performance and affordability of investment.

- Recording profile: The self-developed recording software provides the full parametric record.

- Control method: All models equipped with surface computer provide digitalised operation.

- Automated roasting process: The actions of “charge, discharge and unloading” are automated.

- Replication of the flavour and taste: Utilisation of computer real-time algorithm backtracking technology in parallel with the million worth technology.

- Thin drum: Made of stainless steel with precise temperature control that is sensitive to the temperature changes suitable for flexible techniques.

- Internal stirring in the drum: Precision motor technology makes fine adjustment precise to 5rpm of drum rotation speed. Both clockwise and anticlockwise rotation are available.

- Heating technology: Globally unique short-wave infrared radiation direct heating technology with specialised transmittance for the grains.

- The comfort of the environment: low emission of waste heat system allows the machine to keep itself in a lower temperature, 40 ℃, and the emitted air temperature can be lowered to 100 ℃.

- Exhaust: the utilisation of the DC brushless motor makes the linear damper, precise control and the possibility of fixing rotation speed.

- Silverskin collection: All models equipped with cyclone dust collector helps with the segregation of silverskin and increases the efficiency of roasting.

- Energy consumption: High efficiency and energy saving. One roast costs only 0.6 kWh of electricity.

- Manpower cost: Highly repetitive and specialist-required works can be conducted by computer to reduce labour cost.

The core heating technology combines the patented infrared lamps, the self-developed profile recording system, the panel control, the adjustable drum speed, the comprehensive exhaust system, etc., and the last but not least, the domestically unique technology of replication of profile. Rubasse puts the ideal coffee roasters with low consumption and low manpower requirement into practice. This definitely is the best helper with your roasts no matter for beginners, veterans and owners. Let’s keep up with the trend of the freshly roasted and brewed coffee!

If you would like to get further information about Rubasse, please add our official LINE@ account and Facebook Fanpage @rubassetaiwan to receive the latest news or email us at [email protected].