What is a Differential Pressure Manometer?

A differential manometer is a device that measures the differential pressure between one end to the other end. Installing the manometer sensors in the exhaust pipe enables us to measure the differential pressure between the inner and outer of the roaster drum. The unit for pressure is the pascal (Pa).

Pressure manometers can be generally categorised as mechanical manometers and electronic manometers:

- A mechanical manometer (as shown in the picture) indicates the instant differential pressure with the pointer on the scale.

- An electronic manometer shows the differential pressure precise to decimal places with digital display. The measurement is more accurate, and further, the record of the pressure fluctuations can be kept by computer.

How does Differential Pressure cause?

Exhaust

Hot air roasters generating the hot air from the roasting chamber and blowing into the drum will cause the positive differential pressure. Direct fire and half direct fire roasters are rotating-drum roasters which exhaust the air from the drum by the air pump and generate the negative differential pressure. The cold air outside of the roaster can therefore be introduced into the roasting chamber to be heated.

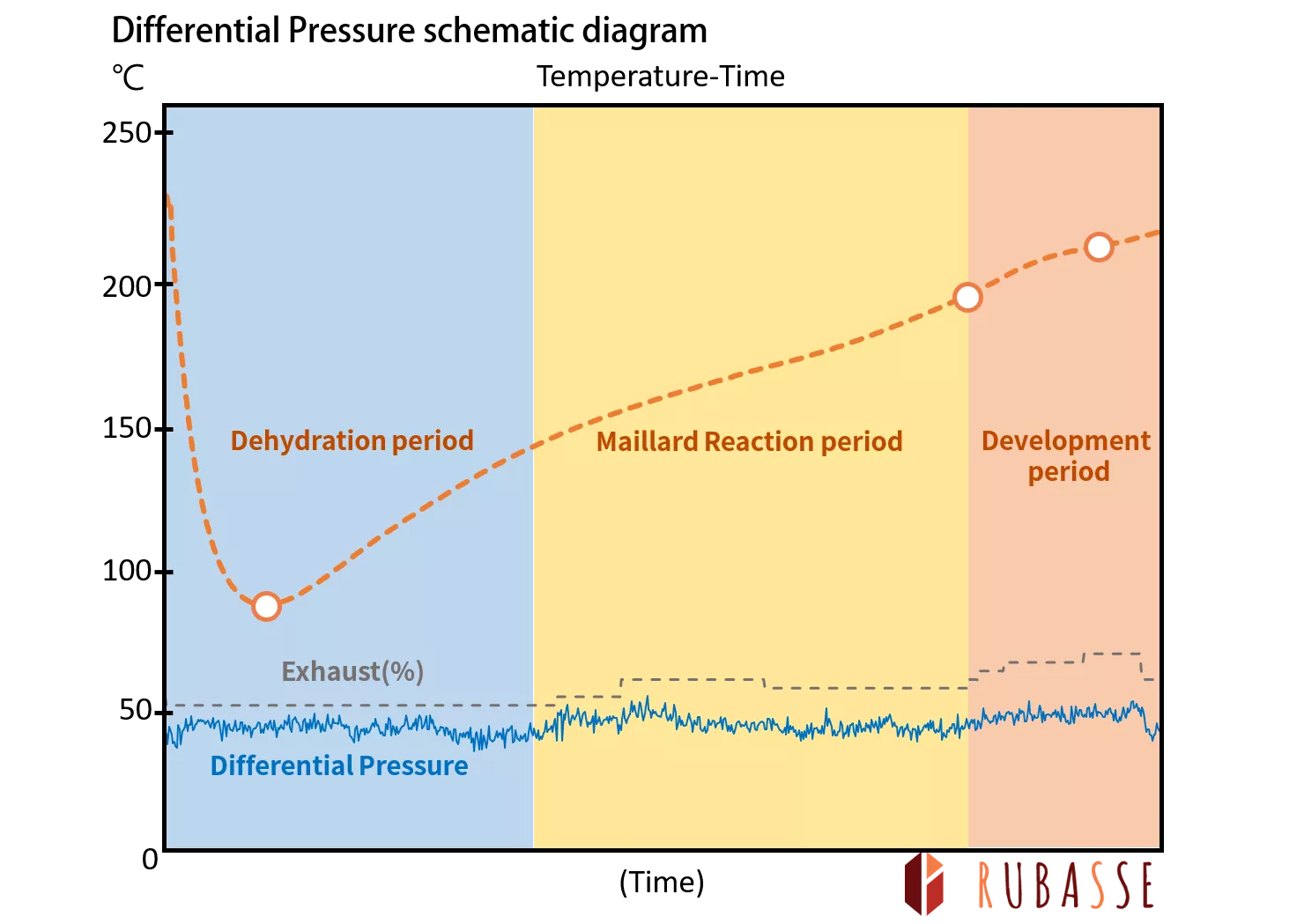

The Reactions of Roasting Process

During the roasting process, the free water slowly evaporates and generates steam inside. Through Dehydration period, Maillard Reaction period and Development period, a variety of chemical reactions make the moisture and carbon dioxide in the cells discharged in a short time. As a result, the humidity, air pressure and the differential pressure between the interior and the exterior of the drum are increased.

Why Observing the Differential Pressure?

*All data is fully parameterised and integrated into the system.

The Correlation between Differential Pressure and Airflow Volume

Bernoulli's Law:

- v is the fluid flow speed at a point on a streamline,

- g is the acceleration due to gravity,

- h is the elevation of the point above a reference plane, with the positive h-direction pointing upward -so in the direction opposite to the gravitational acceleration,

- p is the pressure at the chosen point, and

- ρ is the density of the fluid at all points in the fluid.

- constant is a non-varying value.

Based on Bernoulli’s law, in the case of fixed atmospheric pressure, the variables are (1) and (3), so v2 (velocity, fluid flow speed) is directly proportional to p (fluid pressure), i.e., the differential pressure is directly proportional to the square of an air velocity (exhaust air volume).

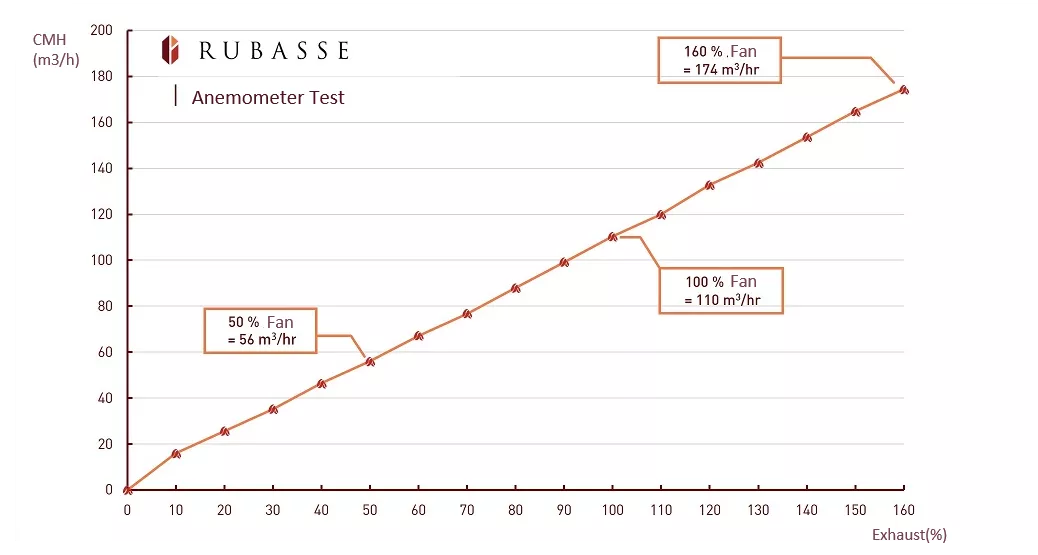

Taking Rubasse Infrared Digital Coffee Roaster as an example, when the exhaust is adjusted to 50% and 100%, the measured differential pressure is relatively around 10 Pa and 40 Pa. We can thus make predictions based on the exact correlation. While roasting, we are able to accurately estimate the instant volume of the airflow based on the differential pressure.

Monitor and Control the Airflow Volume

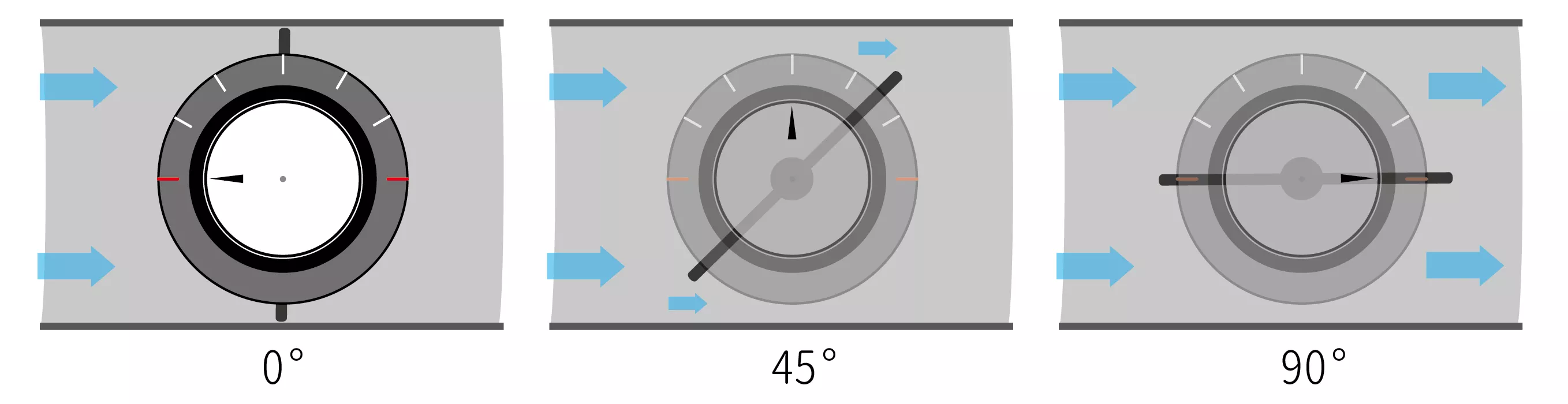

*Conventional damper

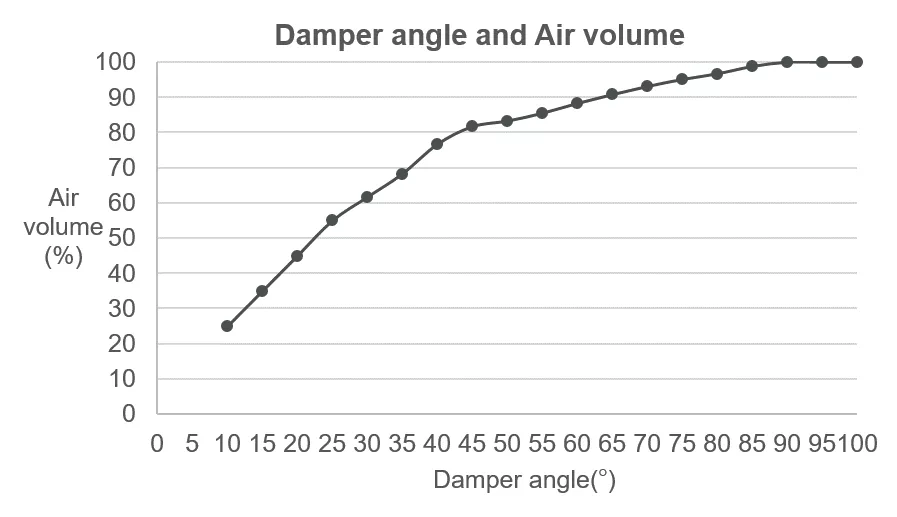

The Correlation between conventional damper and Airflow Volume

If the roaster itself does not have an airflow control system which allow to control the volume precisely, judgements are usually made based on the reading shown on the damper. However, the reading of the damper and the airflow volume are not in linear relationship which may result in inaccurate adjustments.

When the roaster is working, the positive or negative pressure will be produced in the exhaust pipe. According to Bernoulli’s law, we are able to observe the airflow volume through the reading of the differential manometer which also reflects the strength of the air pump. Therefore, the reading can also be considered as the indication of the damper that enables the roaster to monitor and control the airflow volume more precisely and effectively.

Stability of Roasting

In the process of roasting, the grease and dust will adhere to the silver skin collection tray and the exhaust fan. Due to the blockage, the exhausted volume will thus become less and less and greatly reduce the exhaust effect. It will have a profound influence on the roasting result. If using the conventional damper, only when the roaster checks and compares the different batches of the roasted beans several times can he/she find out the problem. During the process, a large quantity of raw beans may be wasted consequently.

Surely, it is recommended to clean the roaster routinely to maintain its performance and functionality. The advantage of using the differential manometer is that when the dust and/ or any other factors start affecting the exhaust effect, which may lead to abnormal correlation between the differential pressure and the air volume, we can immediately determine whether the exhaust pipe is blocked based on the reading of the manometer, and further, make adjustments to the airflow and maintain the differential pressure within the acceptable range. By doing so, we can ensure the quality of the current roasting pot, and then clean the pipes and eliminate the blockage afterwards.

The Effects of the Differential Pressure

Are the Effects of the Drum’s Internal and External Differential Pressures Significant to the Roasting Results?

One standard atmospheric pressure is equal to 101325 Pa. The exhaust of Rubasse Infrared Digital Coffee Roaster will produce a differential pressure of approximately 114 Pa. For a roaster, the difference is not trivial. The actual differential pressure between the interior and the exterior of the drum is calculated to be 0.112% (114 Pa/ (101325 Pa-114 Pa)=0.001126), which is only an approximately one thousandth difference. Therefore, such subtle effect is hardly to be detected.

Effect of High Altitude and Typhoon on Differential Pressure

The evaporation and the boiling of water are the keys during roasting. For example, as we go higher in altitude, the boiling takes place at lower than 100℃ which results in a common situation in the mountains that the instant noodles and meat are hardly to be cooked. It is due to the fact that the pressure is much lower at the top of a mountain than that at its foot. The atmospheric pressure decreases with altitude, and so does the boiling point.

At the altitude of 3000m, the atmospheric pressure is around 70000 Pa, only the seven tenth to the foot). As the atmospheric pressure decreases 100 Pa, the boiling point of water decrease about 0.03℃, i.e., the boiling point goes down from 100℃ to 91℃ (100-30000/100*0.03).

On the typhoon days in Taiwan, there are chances that the pressure decreases from 100200 Pa (the average pressure in summer) to 94000 Pa, an approximately 6% difference (100200 Pa-94000 Pa)/100200 Pa=0.0618), and the boiling point also goes down from 100℃ to 98.14℃ (100-0.03*(100200-94000)/100). Therefore, the impact of the differential pressure can not be underestimated.